Direct tensile test instrument for annular rock sample

A technique for tensile testing and rock samples, applied in instruments, scientific instruments, sampling devices, etc., can solve the problems of large test interference, low actual value, and difficult operation, so as to achieve easy sample preparation and avoid stress concentration , The effect of simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

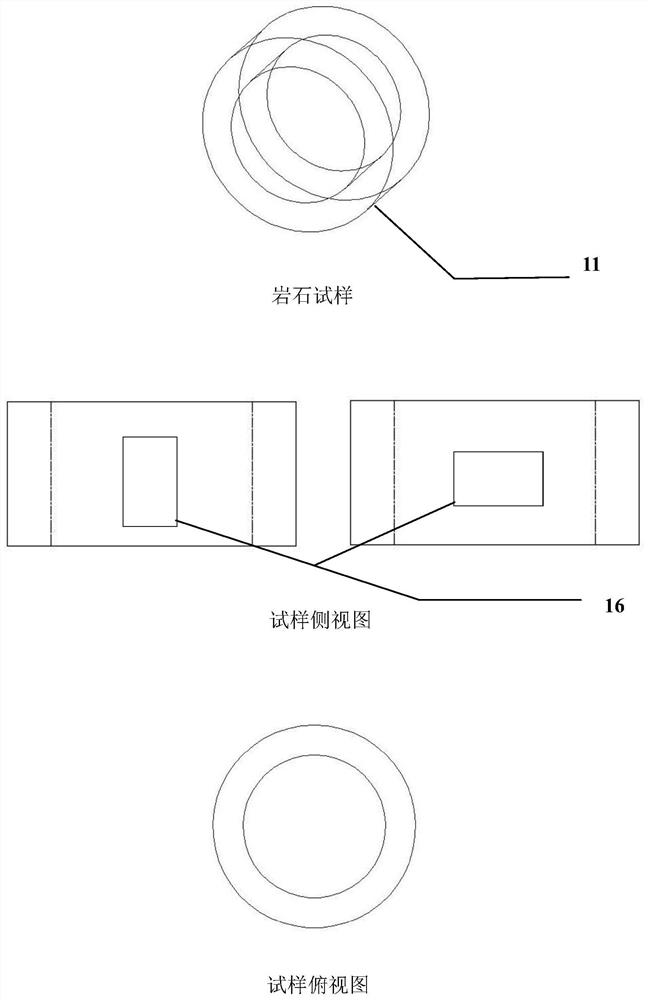

[0059] Step 1. Rock sample preparation

[0060] Prepare the ring sample 11, on the surface of the sample according to figure 2 A strain gauge 16 is attached as shown.

[0061] Step 2. Install the Specimen

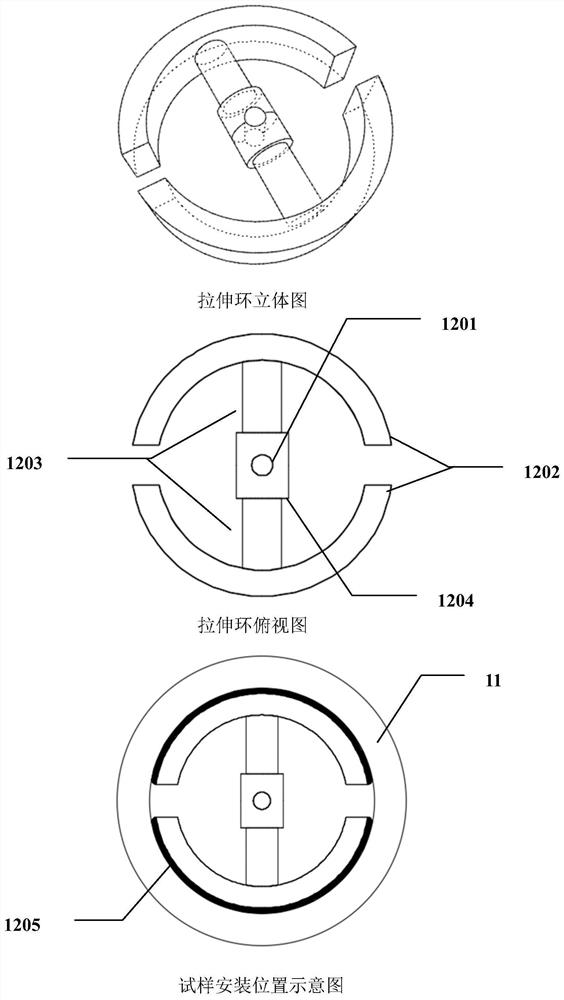

[0062] Unscrew the tension ring oil port 1201, and take off the tempered glass cover 13, such as image 3 Test specimen 11 and tension ring 12 are shown mounted in place. After the sample is installed, install the glass cover and tighten the tension ring oil port 1201.

[0063] Step 3. Exhaust the instrument line

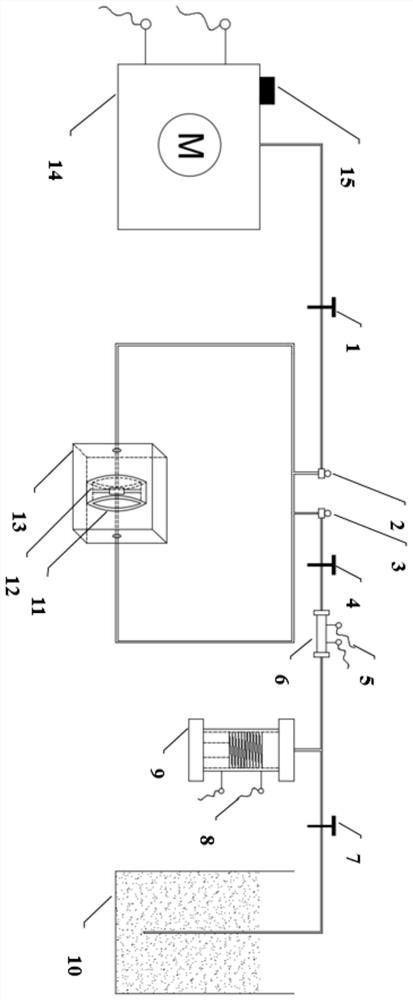

[0064] Open the shut-off valve 1 and the air release valve 3, close the shut-off valve 4, start the hydraulic station 14, inject hydraulic oil into the pipeline, and close the hydraulic station 14, air release valve 3, Stop valve 1.

[0065] Step 4. Add liquid to the servo pump

[0066] Close the shut-off valve 4, open the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com