Experimental device and experimental method for testing mechanical properties of hydrate reservoir

A technology of mechanical properties and experimental equipment, which is applied in the direction of measuring equipment, strength characteristics, and the use of stable shear force to test the strength of materials, etc. It can solve problems such as wellbore instability, safety accidents, increased difficulty and uncertainty in drilling, etc. , to achieve the effect of improving the reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

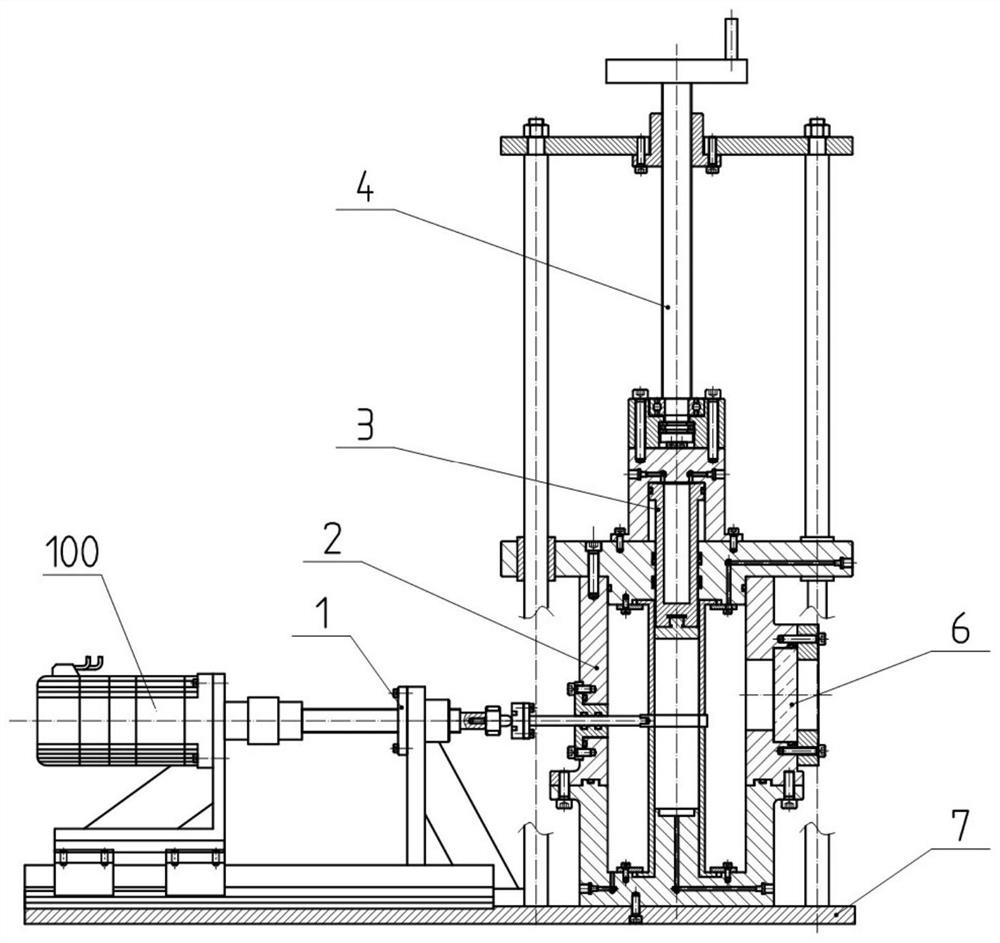

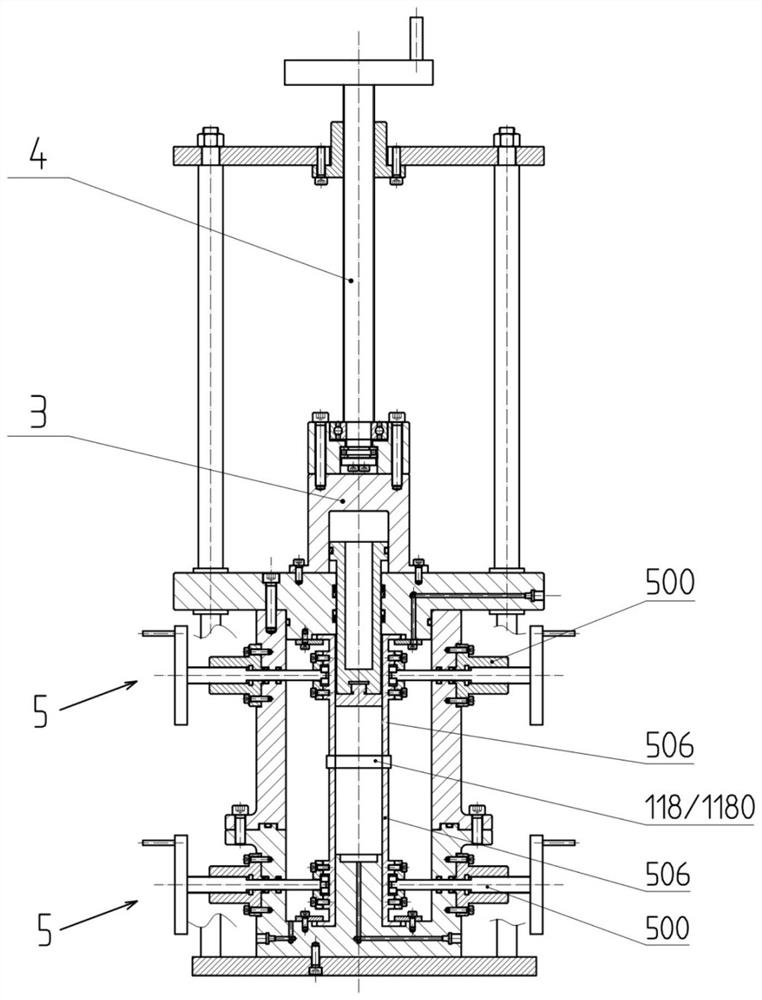

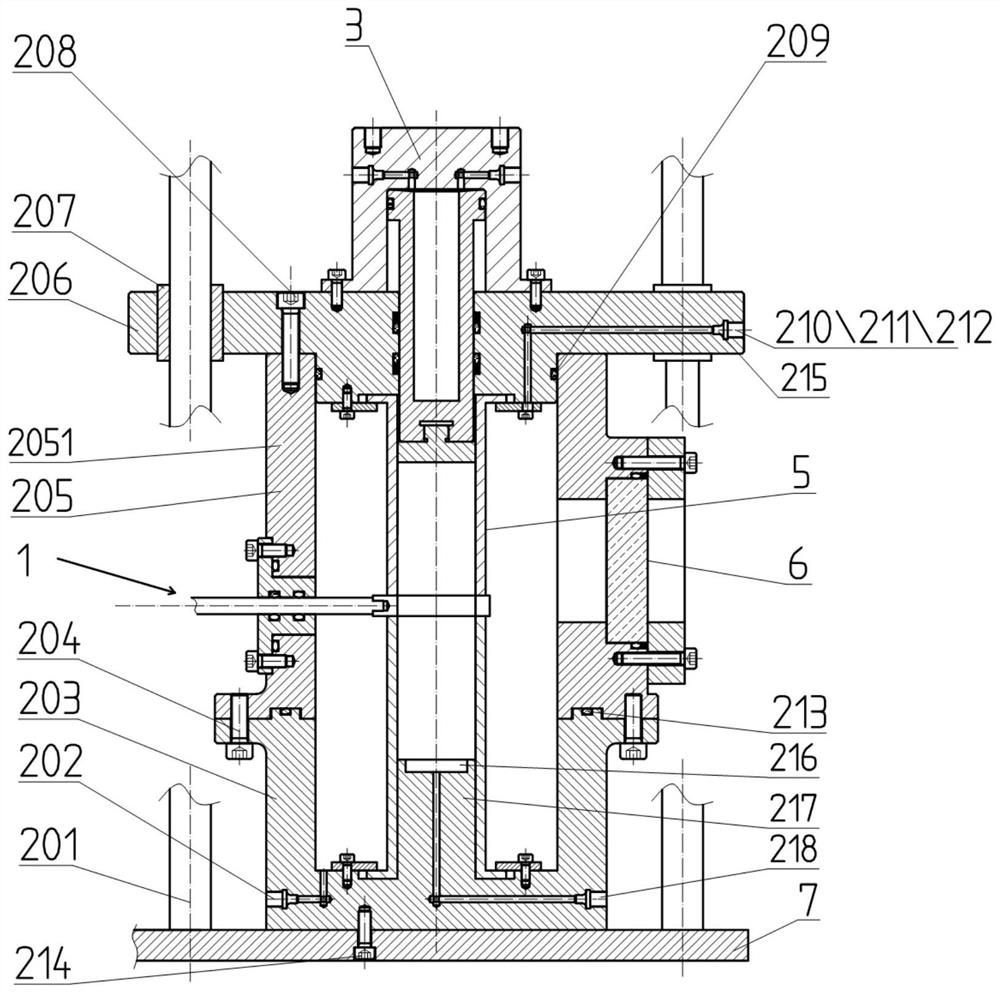

[0075] The invention provides an experimental device for testing the mechanical properties of hydrate reservoirs, such as Figure 1 ~ Figure 3 As shown, the experimental device includes: a reactor 2, a core shear mechanism 1 and a core clamping mechanism 5; the reactor 2 is provided with a drilling fluid inlet 202 and a drilling fluid outlet 215; the core shear mechanism 1 includes a shear drive mechanism 100 And shearing tool 1180, shearing tool 1180 is arranged in reactor 2, and shearing drive mechanism 100 is connected with shearing tool 1180, and shearing drive mechanism 100 can drive shearing tool 1180 to move, to be arranged in reactor 2 The rock core specimen 120 is sheared; the rock core clamping mechanism 5 includes a clamping drive mechanism 500 and a support mechanism 506, the clamping drive mechanism 500 is connected with the support mechanism 506, and the clamping drive mechanism 500 can drive the support mechanism 506 to move to the rock core The sidewalls of the...

Embodiment 2

[0109] The present invention provides an experimental method for testing the mechanical properties of hydrate reservoirs, using the above-mentioned experimental device for testing the mechanical properties of hydrate reservoirs, such as Figure 11 As shown, the experimental method includes: step S10, setting the core test piece 120 in the reactor 2; step S21, clamping the driving mechanism 500 to drive the support mechanism 506 to move away from the core test piece 120; step S22, passing the drilling fluid inlet 202 to feed drilling fluid into the reaction kettle 2, and the drilling fluid is discharged through the drilling fluid outlet 215; step S30, the clamping drive mechanism 500 drives the support mechanism 506 to move to the side wall of the core specimen 120, and the shearing drive mechanism 100 The shearing tool 1180 is driven to move to shear the core sample 120 .

[0110] The mechanical properties of the rock core sample 120 can be understood by shearing the rock core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com