A method for vertical sampling of high-speed railway ballastless track subgrade soil

A technology of ballastless track and high-speed railway, which is applied in the field of foundation soil survey, foundation structure engineering, construction, etc. It can solve the problems of cumbersome assembly procedures, heavy weight, and inability to take out soil samples.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

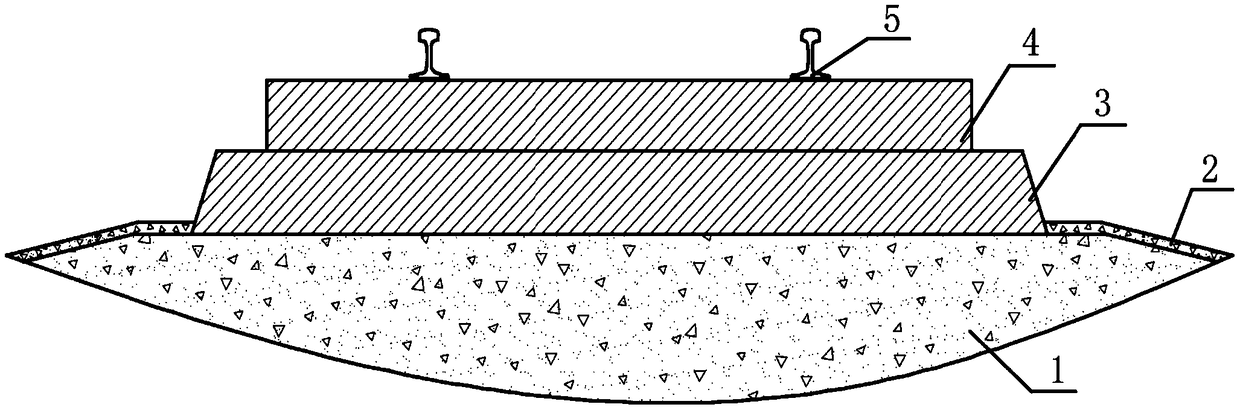

[0028] Such as figure 1 As shown, at present, the upper track structure and subgrade structure of the ballastless track of high-speed railway is that the base plate 3 (or support layer) is laid on the surface layer 1 of the subgrade bed, and the track plate 4 (or track bed plate) is laid on the base plate 3 (or support layer). The rail 5 is laid on the track slab 4 (or track bed slab); the surface layer 1 of the foundation bed is covered with a mortar sealing layer 2, and the mortar sealing layer 2 extends to the side edge of the base plate 3 (or supporting layer). Part of the ballastless track is laid with a CA mortar layer or self-compacting concrete between the base plate 3 (or support layer) and the track plate 4 (or ballast bed plate). For ballastless tracks of high-speed railways, the railway subgrade is the basis for high-speed, stable and safe operation of trains. etc.) and other factors, the current high-speed railway embankment diseases (such as embankment turning m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com