Correction method for rheological test data of coaxial cylinder rheometer

A technology of test data and rheometer, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve problems such as aggravating unsteady flow, affecting researchers, and being unable to obtain rheological parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

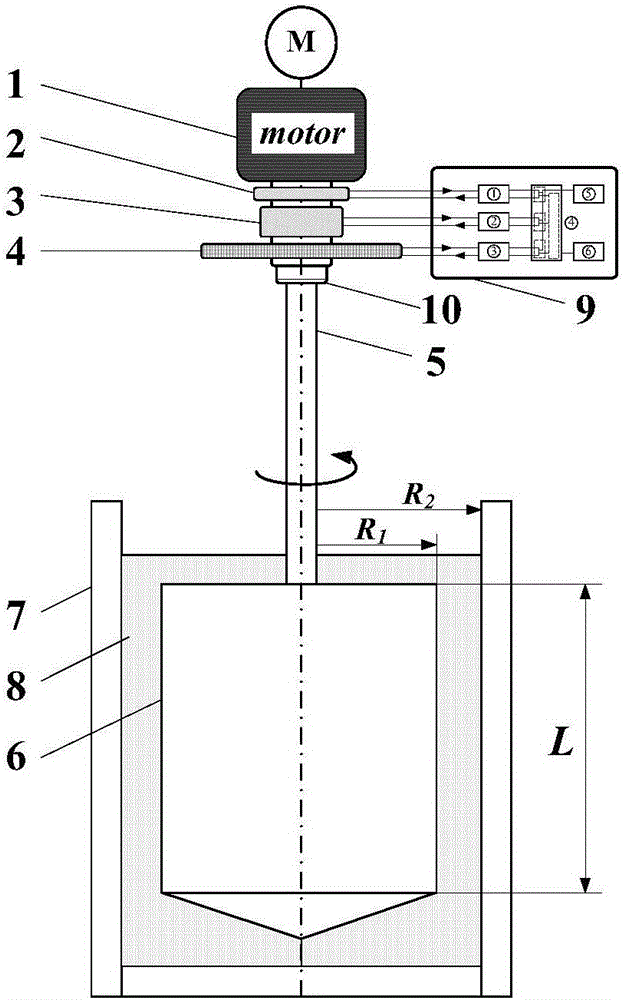

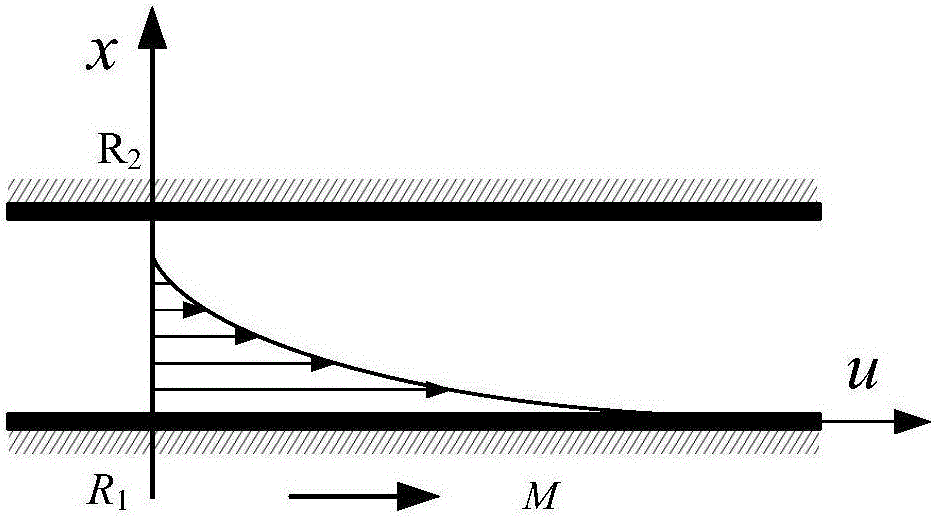

[0054] figure 1 is the actual model of the rotational rheometer coaxial cylinder test system, figure 2 It is a simplified diagram of the model of two infinite parallel plates. figure 1 The width of the measurement gap is much smaller than the height of the measurement fixture. According to the axial symmetry of the flow field in the coaxial cylinder, the model is further simplified to a one-dimensional transient model of the flow field changing along the radial direction, namely figure 2 The Couette flow between two infinitely large plates. and in figure 2 Considering the system inertia in the simplified model, the torque balance relationship at the boundary of the measuring fixture is established. The boundary of the measurement gap includes dynamic boundary and static boundary. The dynamic boundary gradually becomes stable from static in the initial process, and the flow field also gradually develops from static to stable.

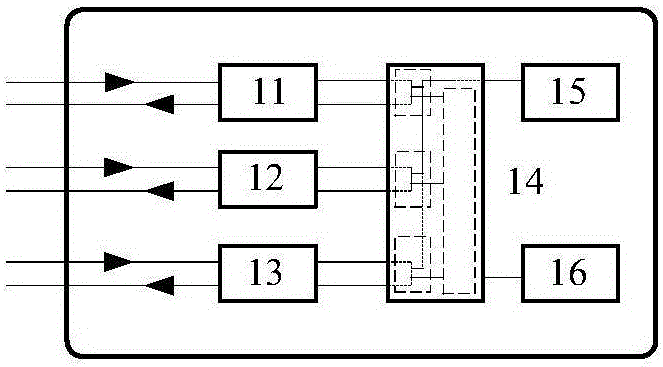

[0055] Such as figure 1 — Figure 4 As sh...

Embodiment 2

[0077] A method for correcting rheological test data of a rotational rheometer cone-plate system or a flat-plate system, the specific steps are as follows:

[0078] Step 1: Put the sample to be tested in the cone-plate system or plate system of the rotational rheometer;

[0079] Step 2: Carry out experiments in the setting mode and collect data;

[0080] Step 3: Introducing the torque correction item of shear stress to calculate the corrected fluid shear torque, and the corrected rotational rheometer cone-plate system or flat-plate system to measure the real shear stress and real transient viscosity at the boundary of the fixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com