A high-performance neutron collimator and its assembly method

A collimator and high-performance technology, applied in the direction of using the diaphragm/collimator, etc., can solve the problems of narrow neutron beam energy range, lower collimation performance, large beam divergence, etc., and achieve easy machining and high effect Good, high performance collimation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

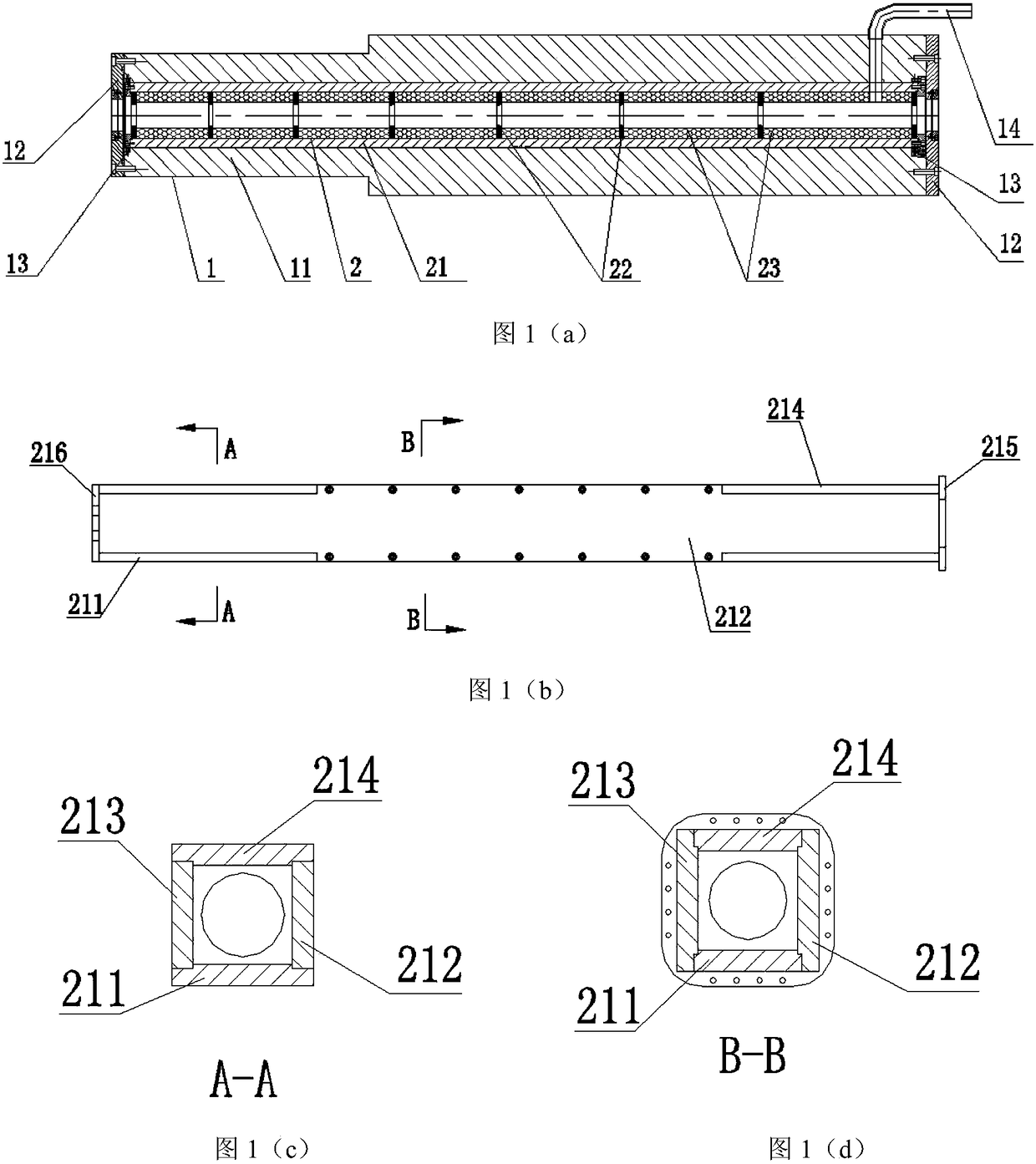

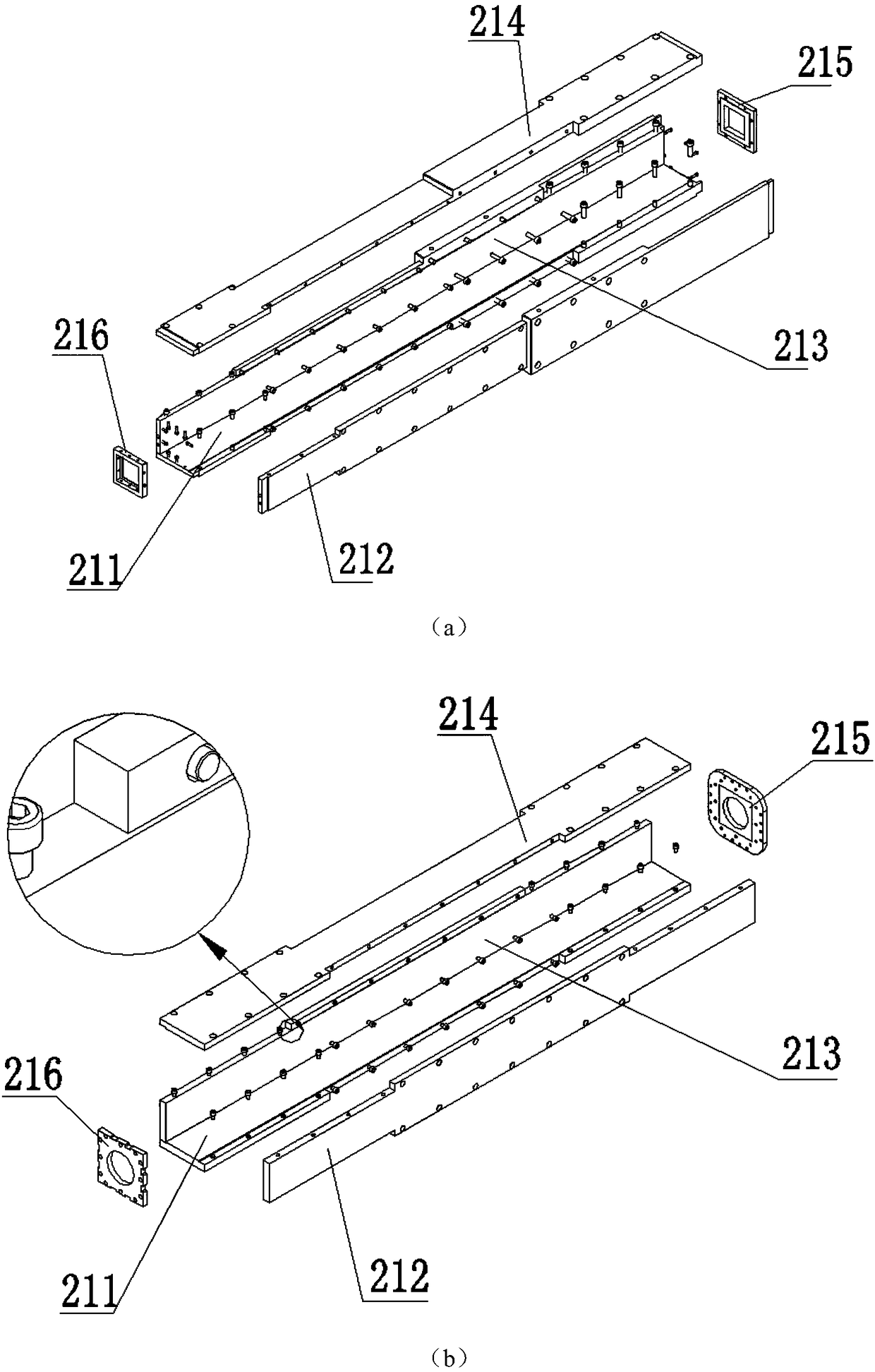

[0042] Accompanying drawing 1 is a schematic diagram of a high-performance collimator. Take this as an example to further illustrate the specific implementation of the present invention.

[0043] First complete the assembly of the collimation plug-in 2: firstly remove the top plate of the plug-in housing assembly 21 and the large end flange of the housing, and then install the blocking blocks and shielding blocks one by one from the side of the small end flange of the housing, Then install the large end flange of the plug-in housing and the top plate of the housing, then install the screws (initial screwing) and positioning pins to accurately reset the relative positions between the boards, and finally tighten all the screws.

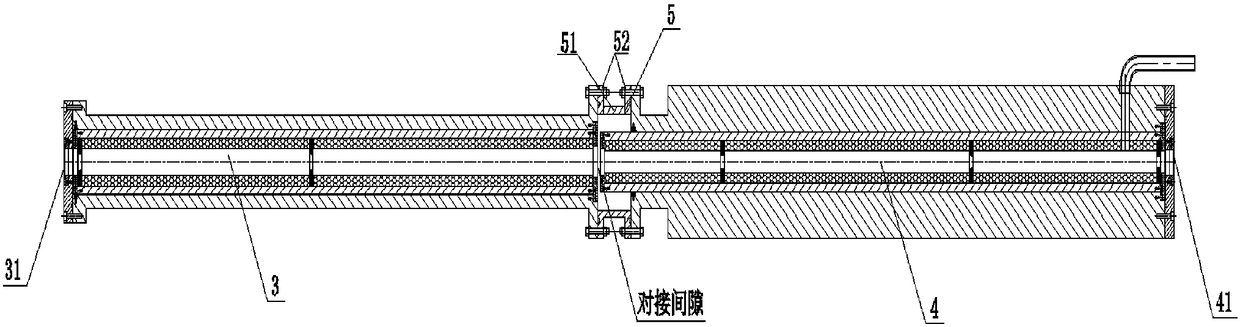

[0044] Push the assembled collimation insert 2 into the inner cavity of the vacuum chamber assembly 1 from one end until the fixed flange at one end of the collimation insert is aligned with the embedded end face of the vacuum chamber, and then adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com