An energy-saving excitation current-conducting iron core reactor

A reactor and iron core technology, applied in the direction of magnetic core/yoke, transformer/inductor magnetic core, circuit, etc., to achieve huge benefits, good effects, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

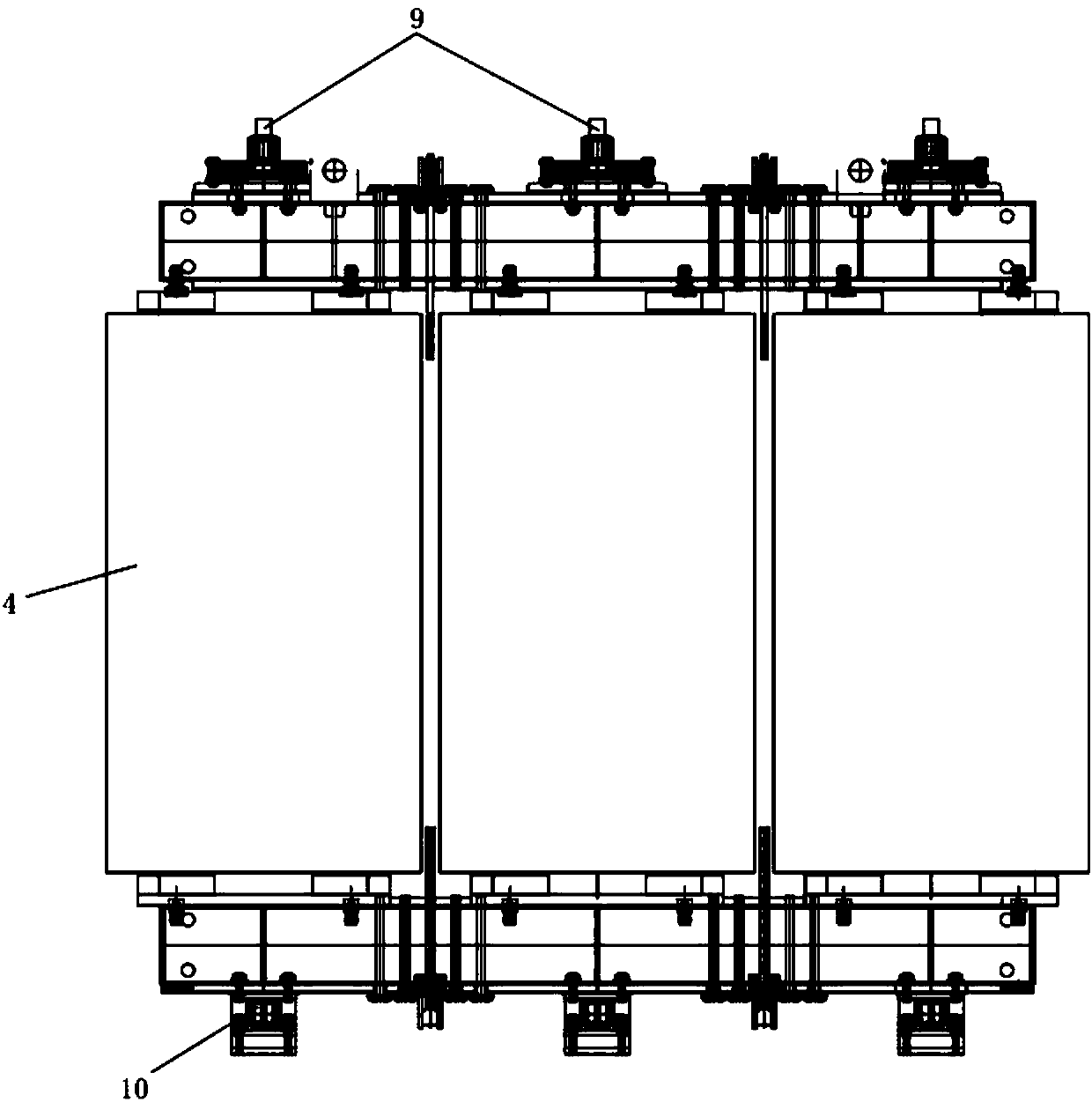

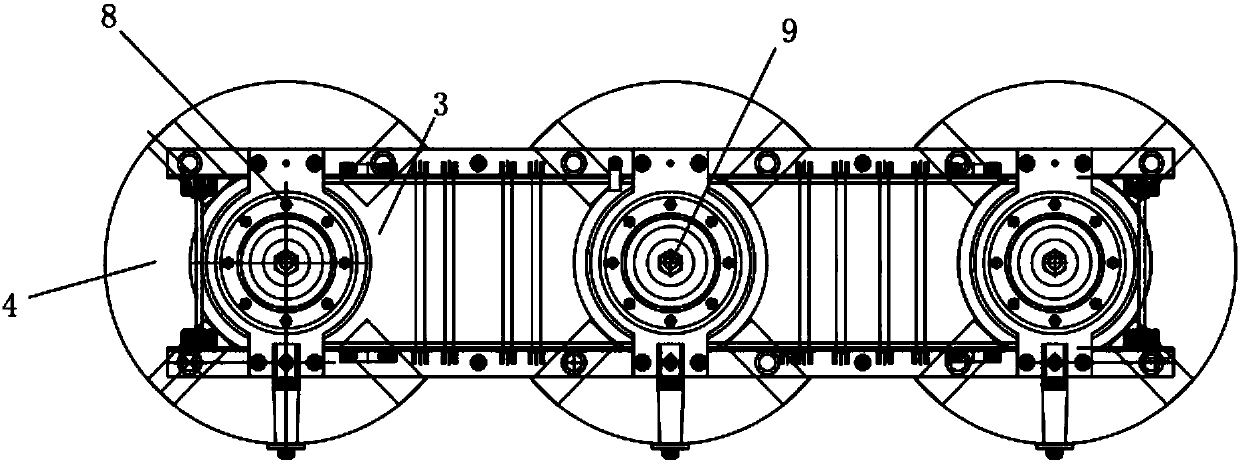

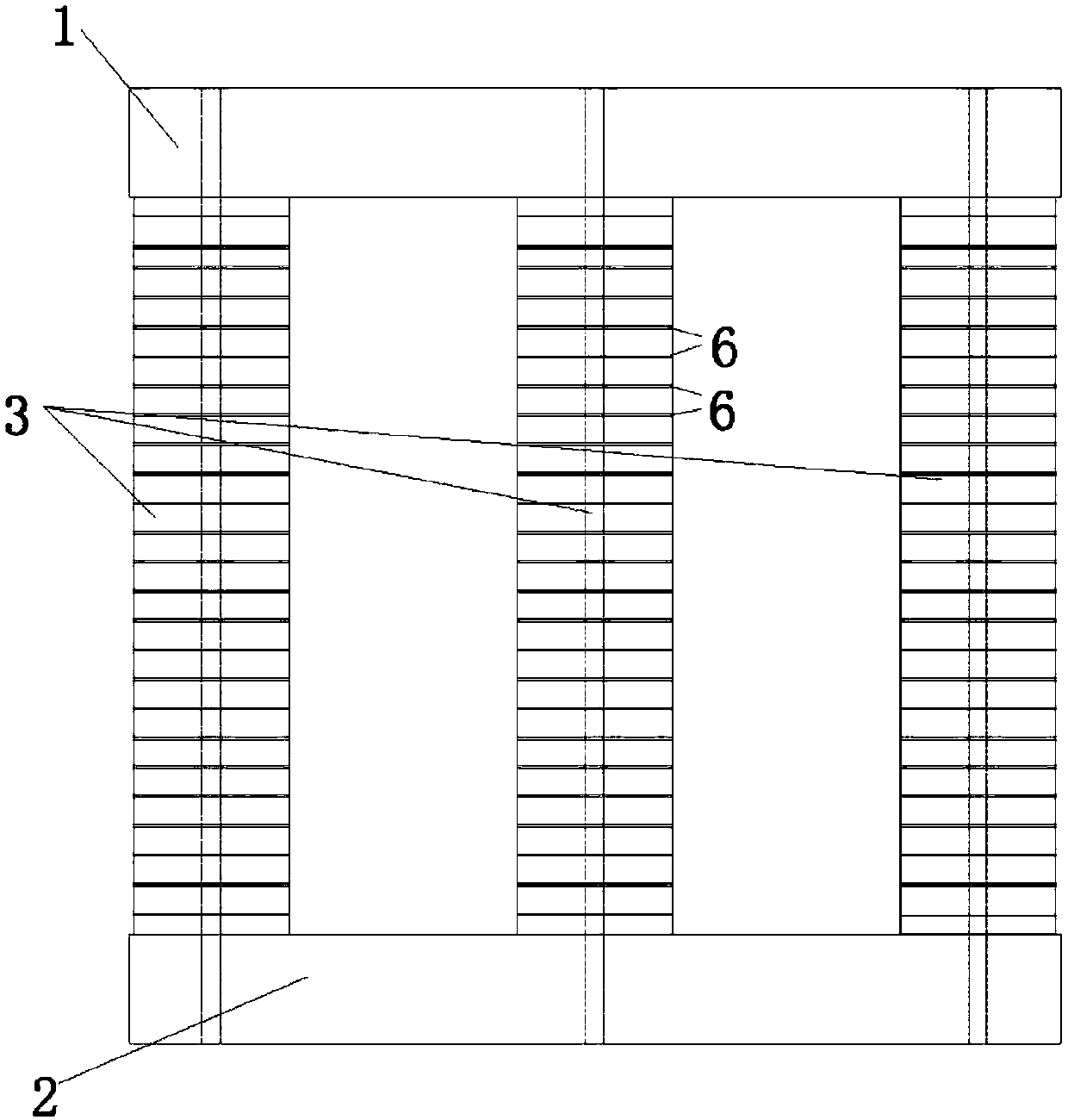

[0032] Such as figure 1 , 2 . As shown in 3, an energy-saving excitation current-conducting iron core reactor includes an iron core, and the iron core includes an upper iron yoke 1, a lower iron yoke 2, a core column 3 and an iron core assembly device, and the core column 3 is located on the upper iron yoke 1 and the lower iron yoke 2, and the coil 4 is hidden outside the core column 3. The core column 3 is formed by stacking a number of magnetic conductive cakes 5, and a gas coil is arranged between every two adjacent magnetic conductive cakes 5. Gap plate 6; the upper and lower ends of the core column 3 are provided with a hollow magnetic cake 7, and the iron core assembly includes a pressing plate 8, a central pull rod 9 and a base 10, the pressing plate 8 is arranged above the upper iron yoke 1, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com