A kind of polyethylene oxide based electrolyte and its preparation method and application

A technology of polyethylene oxide and electrolyte, which is applied in the field of lithium-ion battery electrolyte materials, can solve the problems of decreased mechanical properties, low vapor pressure, easy crystallization, etc., and achieves the effects of improving chain segment motion ability, increasing ion conductivity, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] Specifically, the preparation method includes the following steps:

[0055] (1) Compound of formula II and compound of formula III are mixed in the first solvent at a molar ratio of 2:1 to 5:1, fully reacted at 40°C to 60°C, precipitated with glacial ether or n-hexane, washed and dried to obtain A compound of formula IV; the first solvent is one or more of dimethyl sulfoxide and N,N-dimethylformamide; during the reaction, a molar mass of the compound of formula III can also be added 1 / 3 to 1 of the base to promote the reaction; the compound of formula II is preferably methoxy mono-capped polyethylene oxide, butoxy mono-capped polyethylene oxide, octyloxy mono-capped polyethylene oxide, decyl One or more of oxygen mono-terminated polyethylene oxides, the relative molecular weight is 350-2000, preferably 550-750, when the molecular weight is too small, the prepared compound of formula I cannot meet the coordination requirements with lithium salt , and the molecular weigh...

Embodiment 1

[0068] The chemical structural formula of the polyoxyethylene-based electrolyte of Example 1 is shown in Formula I, wherein R1 is methoxy, R2 is methyl, m is 8, and x is 0.1.

[0069] The preparation method of polyoxyethylene-based electrolyte provided by the invention comprises the following steps:

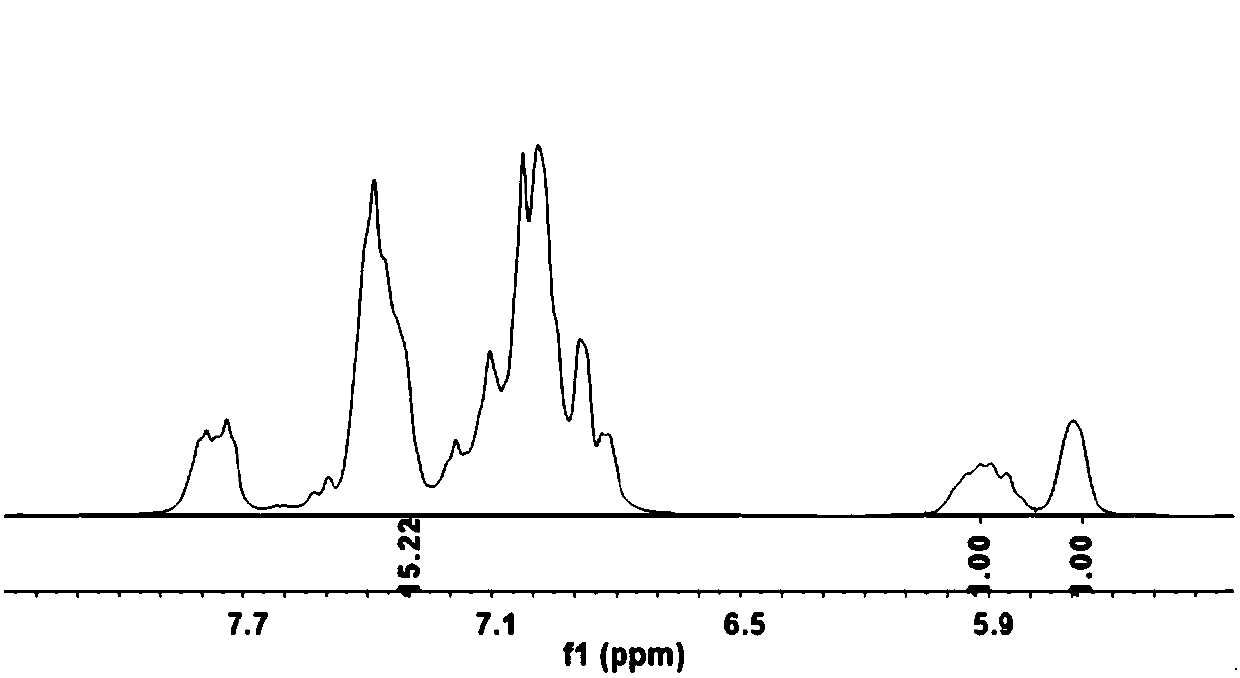

[0070] (1) Add the industrial product polyetheretherketone (structural formula VI) into concentrated sulfuric acid so that the mass volume ratio of polyetheretherketone to concentrated sulfuric acid is 1g:10ml, stir at room temperature, fully dissolve, and then heat up Carry out sulfonation reaction at 30°C for 24 hours, then precipitate with ice water, filter, and dry to obtain sulfonated polyether ether ketone (the structural formula is shown in formula VII), and its NMR spectrum is as follows: figure 1 As shown, it can be seen that 5.7 and 5.9 are the -CH and -OH shifts after carbonyl reduction on SPEEK, and -CH on the benzene ring is at 6.7ppm to 7.9ppm;

[0071] (2) Dissolv...

Embodiment 2

[0076] The chemical structural formula of the polyoxyethylene-based electrolyte of Example 2 is shown in Formula I, wherein R1 is butoxy, R2 is methyl, m is 12, and x is 0.2.

[0077] The preparation method of polyoxyethylene-based electrolyte provided by the invention comprises the following steps:

[0078] (1) Add the industrial product polyetheretherketone (structural formula VI) into concentrated sulfuric acid so that the mass volume ratio of polyetheretherketone to concentrated sulfuric acid is 1g:12ml, stir at room temperature, fully dissolve, and then heat up Carry out sulfonation reaction at 35° C. for 18 hours, then precipitate with ice water, filter, and dry to obtain sulfonated polyether ether ketone (structural formula shown in formula VII).

[0079] (2) Dissolve the sulfonated polyether ether ketone obtained in step (1) in the organic solvent N,N-dimethylformamide, and add a reducing agent, aluminum isopropoxide, so that aluminum isopropoxide and sulfonated polyet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com