Elastic component for resonant motor and resonant motor

An elastic component and resonance technology, applied in the field of micro-motors, can solve the problems of poor reliability of linear motor vibration, waste of electric energy, high power consumption, etc., and achieve the effects of good reliability, reduced production cost, and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

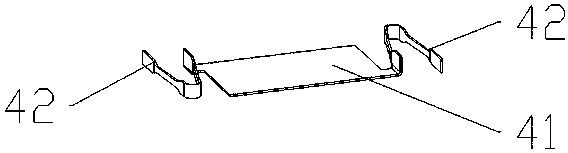

[0033] Such as figure 1 As shown, an elastic component 4 for a resonant motor, the elastic component 4 is used to carry the magnetic material in the resonant motor, and cooperate with the magnetic material to make the resonant motor vibrate, including The main body 41 of the magnetic material, and the elastic structures 42 arranged on both sides of the main body 41, the main body 41 and the elastic structures 42 at both ends are integrally formed.

[0034] The elastic structures 42 on both sides of the main body 41 may be one as shown in the figure, or may be multiple, which should not be limited by this embodiment.

Embodiment 2

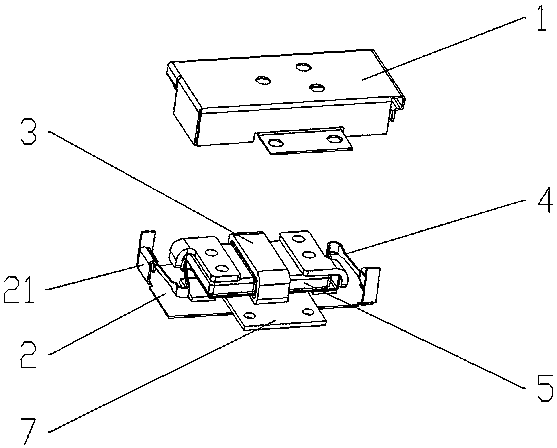

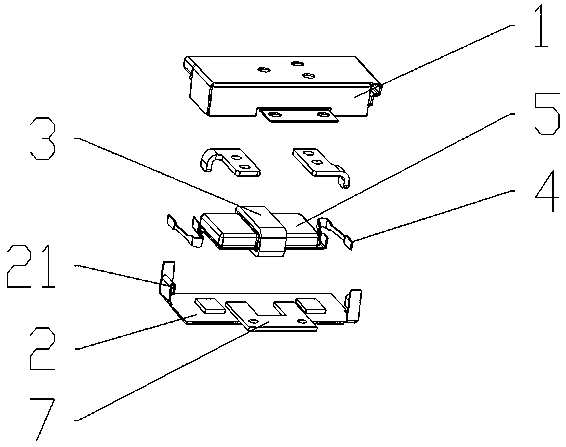

[0036] Such as Figure 2-5 As shown, a resonant motor, preferably but not limited to a cuboid shape, includes an upper shell 1 and a lower shell 2 combined together, the upper shell 1 is a boxed structure with the opening downward, the upper shell 1 and the The space surrounded by the lower shell 2 is provided with:

[0037] Coil 3: the coil 3 is fixed on the lower shell 2, and the polarity direction of the magnetic field generated by it is parallel to the vibration direction of the resonant motor;

[0038] The elastic component 4 described in Embodiment 1: the elastic component 4 is arranged in the hollow cavity surrounded by the coil 3, and is used to carry the magnetic material 5 in the resonant motor and cooperate with the magnetic material 5 Vibrating the resonant motor includes a main body 41 for carrying the magnetic material 5, and elastic structures 42 arranged on both sides of the main body 41 for connecting the upper shell 1 or the lower shell 2, the The main body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com