Output roller bed capable of achieving automatic laying of bars

An output roller table, automatic technology, used in cooling beds, metal processing equipment, metal rolling and other directions, can solve the problems of inconsistent temperature, uneven stress state, affecting the life of the cutting edge, etc., to ensure overall performance and temperature uniformity. Consistent, avoids the effect of shearing elbows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

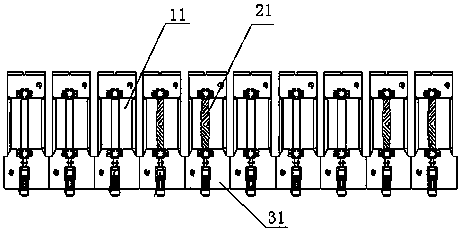

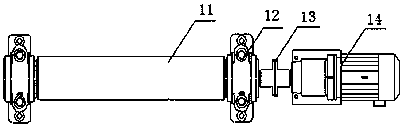

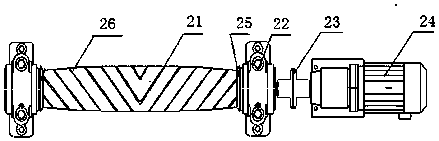

[0021] Refer to attached figure 1 , 2 3. An output roller table capable of automatically laying bars, comprising a plurality of smooth rollers arranged in parallel, the smooth rollers are cylindrical, and an ellipse is arranged between the smooth rollers arranged in parallel. Tiling vibrating roller 21, described ellipse tiling vibrating roller 21 is ellipse, is provided with round steel 26 on elliptic tiling vibrating roller 21, and described round steel 21 is along the The roll surface of the elliptical flat vibrating roll 21 is in a spiral distribution.

[0022] The installation quantity of ellipse paving vibratory roller 21 can be decided according to the length of bar material, in the present embodiment, with reference to attached figure 1 , four elliptical vibrating rollers 21 are arranged between the smooth rollers.

[0023] Refer to attached figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com