Aerosol-generating system having a fluid-permeable heater assembly

An aerosol generation and heater technology, applied in heating elements, heating element materials, ohmic resistance heating parts, etc., can solve the problems of fragile electrical connections, difficult to manufacture in a low-cost and repeatable manner, and difficult to dispose of. , to achieve the effect of simple connection and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

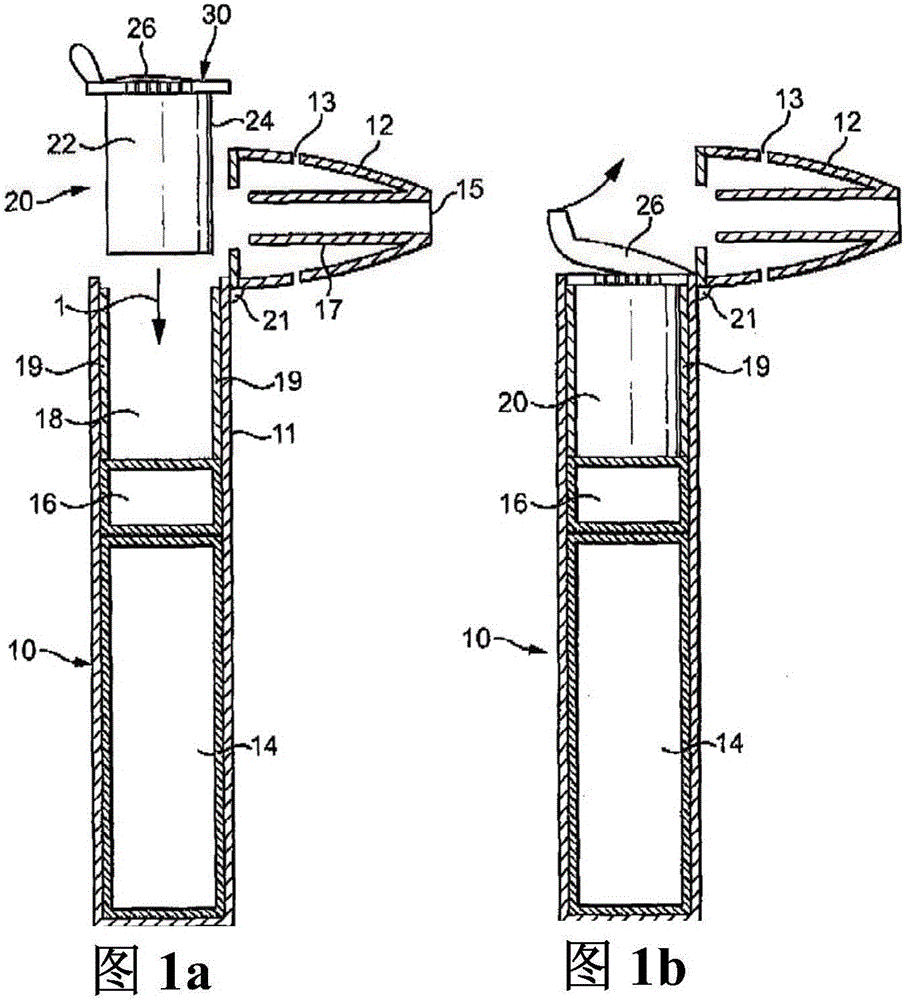

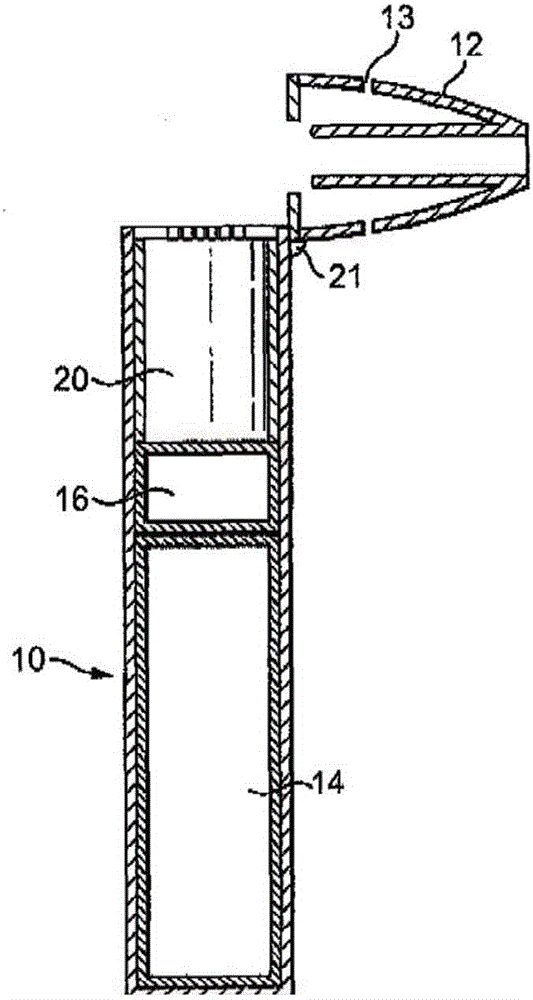

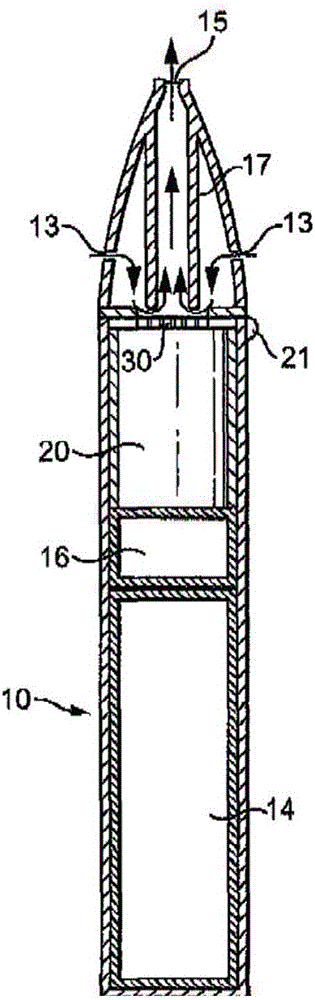

[0067] Figures 1a to 1d is a schematic diagram of an aerosol generating system comprising a cartridge according to an embodiment of the invention. Figure 1a It is a schematic diagram of the aerosol generating device 10 and the separating cartridge 20 forming the aerosol generating system together. In this example, the aerosol generating system is an electrically operated smoking system.

[0068] Cartridge 20 contains an aerosol-forming substrate and is configured to be received within cavity 18 within the device. When the aerosol-forming substrate provided in the cartridge 20 is exhausted, the cartridge should be replaceable by the user. Figure 1a Cartridge 20 is shown prior to insertion into the device, wherein Figure 1a Arrow 1 in indicates the direction of cartridge insertion.

[0069] The aerosol-generating device 10 may be a smoking device and may be of comparable size to a conventional cigar or cigarette. The device 10 comprises a body 11 and a mouthpiece portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com