Device and method used for detecting sealing piece

A technology for closures and closed containers, which is applied in the directions of closures, optical devices, measuring devices, etc., can solve problems such as identification problems and unreliable gap sizes, and achieve the effect of improving product reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

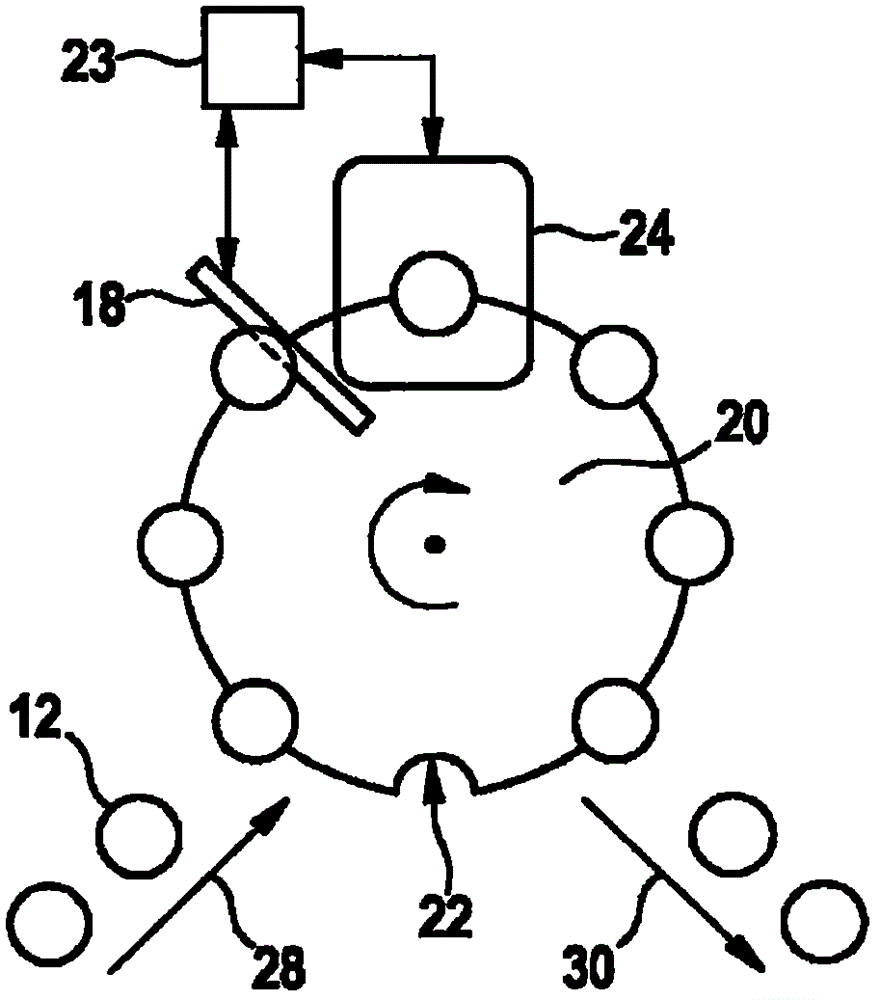

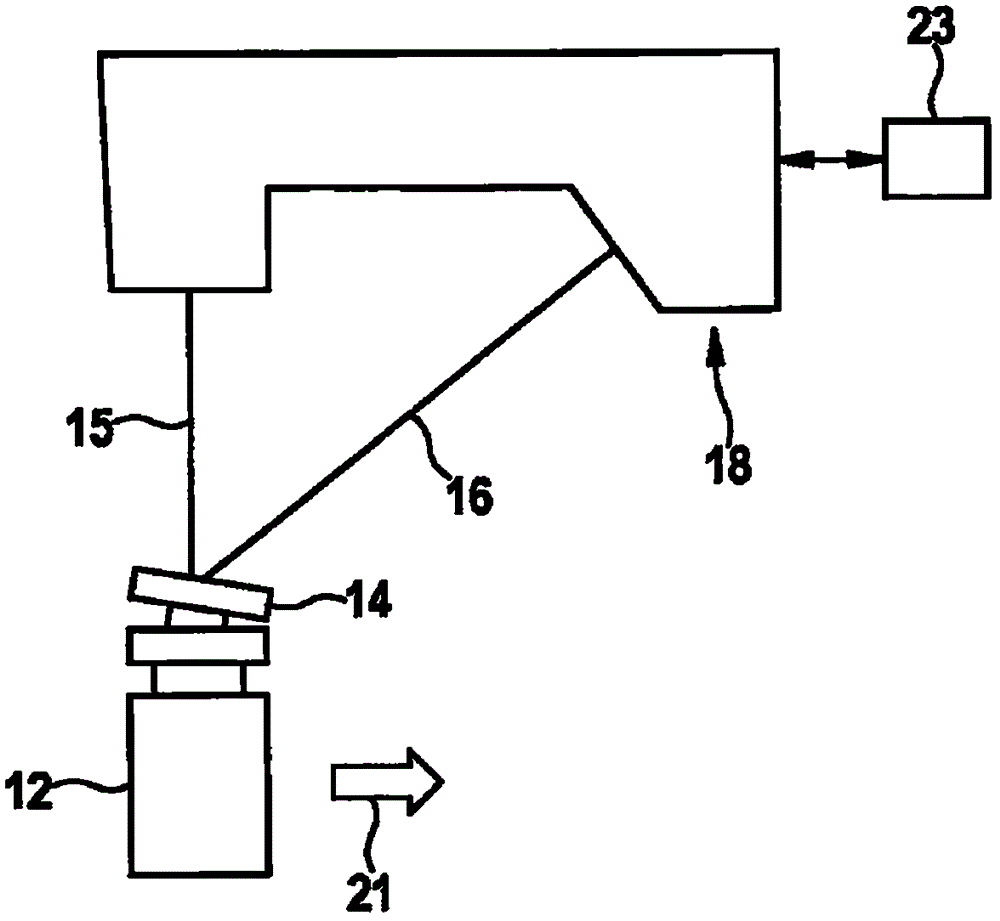

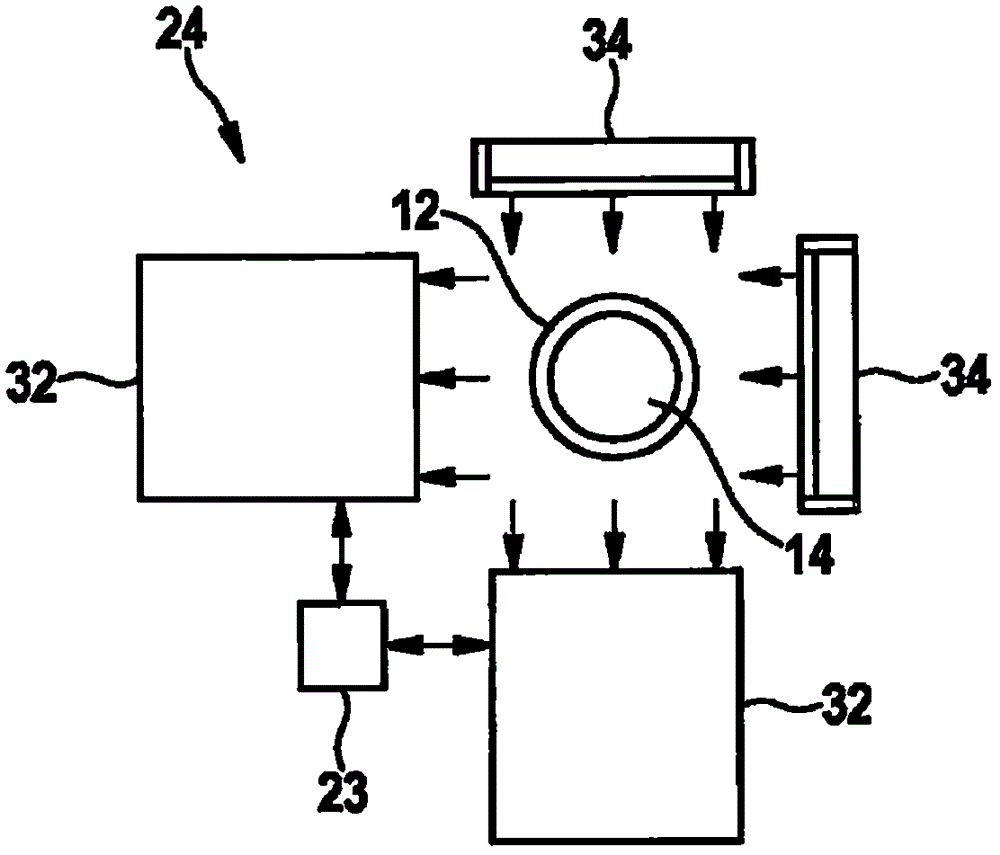

[0020] The container 12 is conveyed to the conveying device 20 through the inlet 28. The container 12 has been filled with product, such as liquid medicine, and closed by the closure 14 at a previous, not shown work station. in figure 1 The device shown in is used for checking the closure area or for checking the size of the gap formed between the container 12 and the closure 14. The conveying device 20 is configured as a conveying star, for example. The conveying device 20 has a receiving portion 22 on the outside, in which the container 12 can be fixed. The transfer device 20 rotates clockwise. Therefore, the container 12 first reaches the sensing area of the sensor 18 for determining the height profile. The sensor 18 for determining the height profile is arranged above the conveying path of the container 12. By way of example, the sensor is constructed linearly and at least partially covers the surface of the closure 14 closing the container 12. The sensor 18 for dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com