A Real-time Judgment Method of Drill Pipe Working State in Hydraulic Decoking Process

A hydraulic decoking and working state technology, applied to measuring devices, instruments, measuring ultrasonic/sonic/infrasonic waves, etc., can solve problems such as equipment and personnel damage, affecting production efficiency, etc., achieve high compliance, improve judgment accuracy, and judge good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

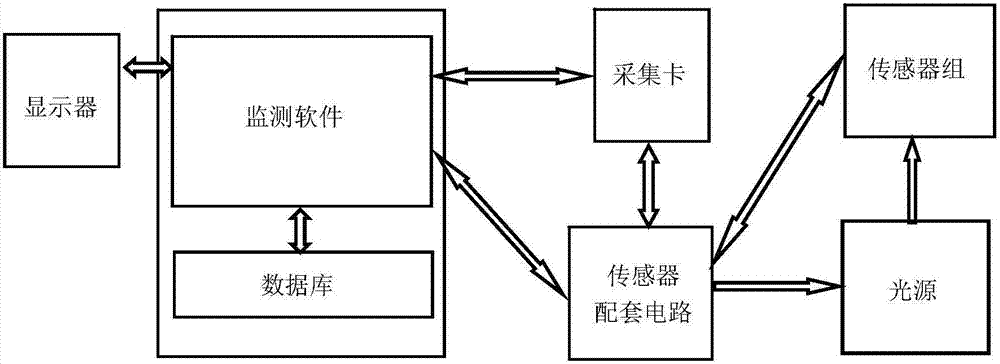

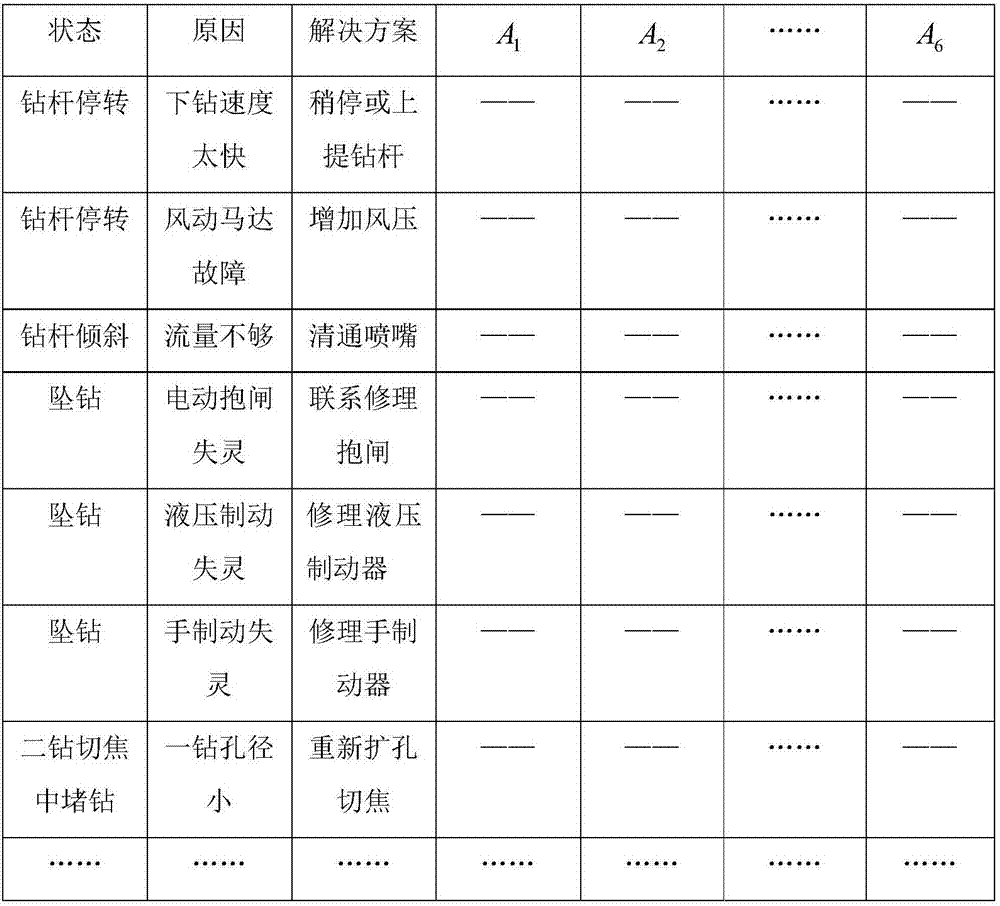

[0022] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

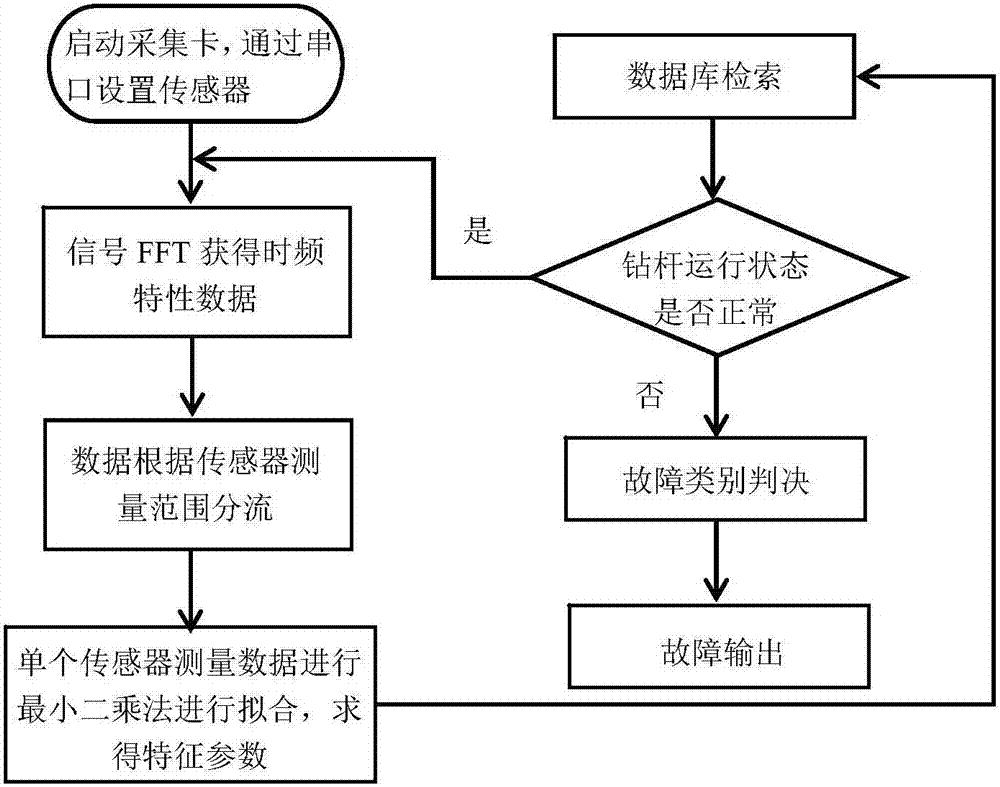

[0023] The invention provides a real-time judgment method for the working state of the drill pipe in the process of hydraulic decoking, such as figure 2 As shown, it includes the following steps:

[0024] S1. Signal collection:

[0025] Through the acoustic vibration sensor arranged on the coke tower wall (usually the outer wall) along the height direction of the coke tower, the acoustic vibration signal of the coke injected by the high-pressure water onto the inner wall of the coke tower is collected in real time, thereby obtaining the instantaneous spectrum data of the acoustic vibration signal;

[0026] During the decoking process, the height of the drill bit and the rotation speed signal of the drill pipe are obtained in real time;

[0027] S2. Data splitting: according to the occurrence position of the acoustic vibration signal, select the aco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com