Substrate detection equipment

A technology for substrate detection and equipment, applied in measuring devices, optical testing of flaws/defects, and material analysis through optical means, can solve problems such as high equipment manufacturing costs and low efficiency, and achieve the effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

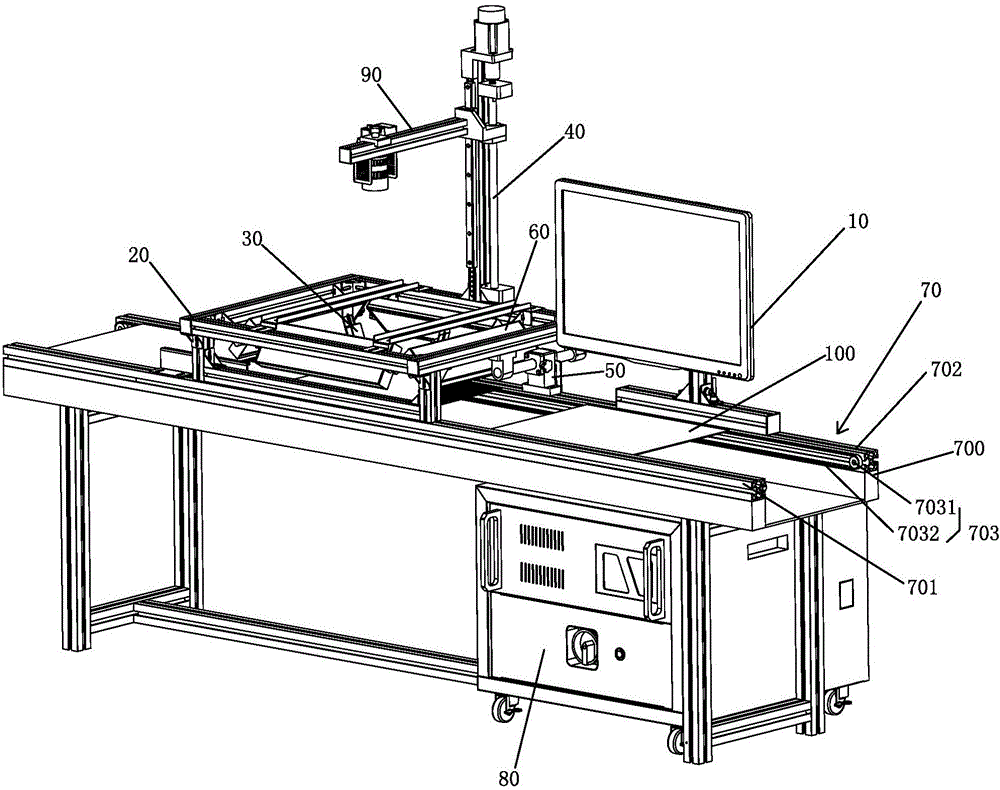

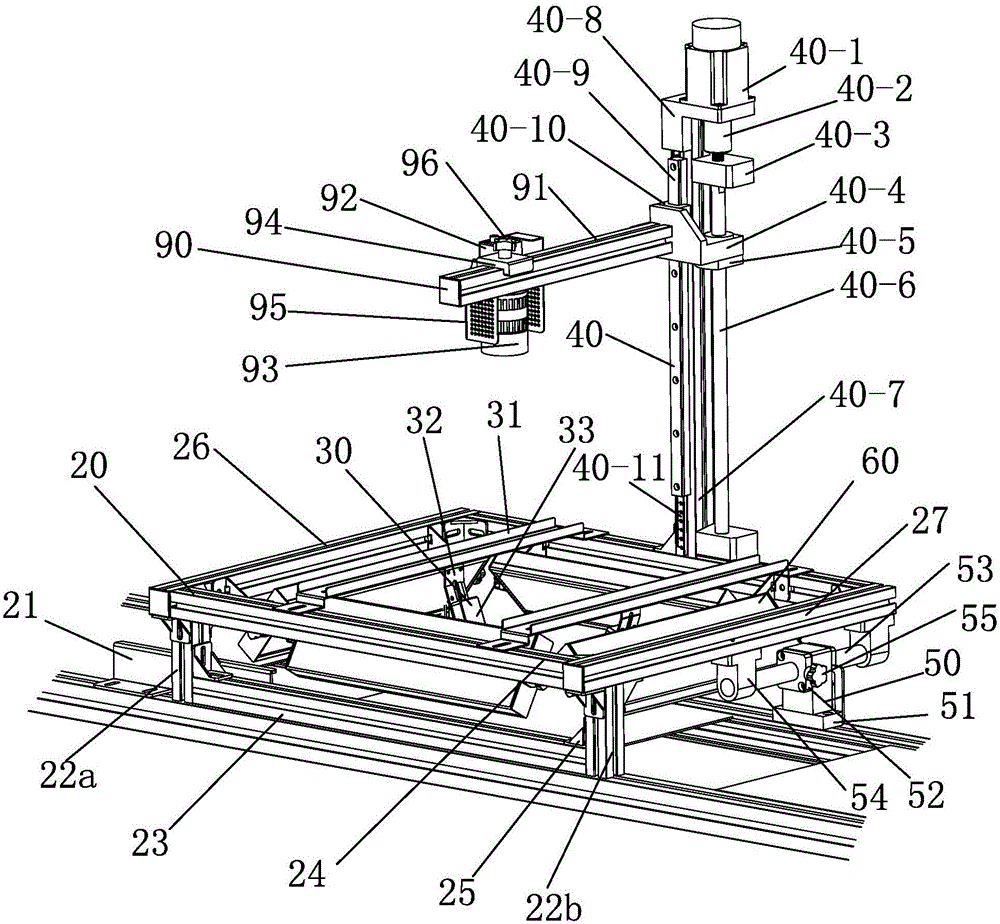

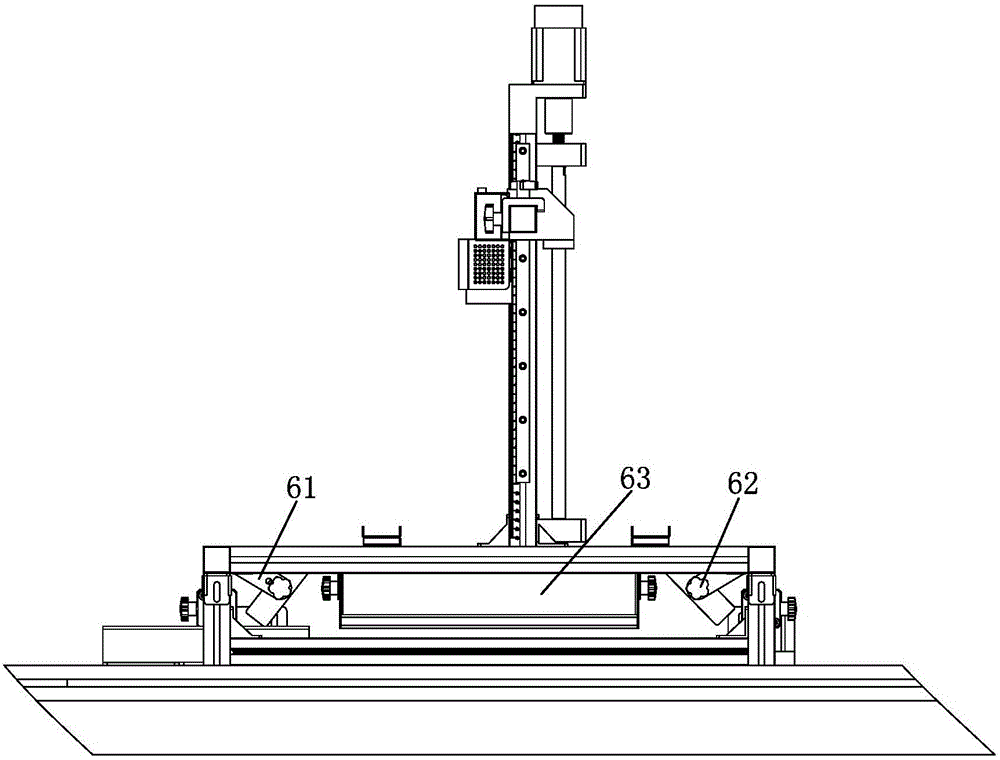

[0021] Please combine Figure 1 to Figure 4 For reference, the present invention provides a substrate inspection device, which is suitable for defect inspection of a substrate 100 such as a PCB circuit board or other plate-like workpieces. The substrate inspection equipment includes:

[0022] The transport mechanism 70 is used for transporting the substrate 100 . The transport mechanism 70 may be a SMT (Surface Mount Technology, Surface Mount Technology) production line or a docking station, which transports the substrate 100 from a previous process to a subsequent process.

[0023] The imaging mechanism 90 is arranged opposite to the conveying mechanism 70 , and is used to photograph the substrate 100 transported on the conveying mechanism 70 at a specific position to generate a complete image. The complete image can be understood as a panoramic i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com