Corn integral processing device

A comprehensive processing and corn technology, applied in threshing equipment, applications, agricultural machinery and implements, etc., can solve the problems of inability to handle, low threshing efficiency, complex structure, etc., to achieve the effect of simple structure, avoidance of repetitive labor, and efficient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

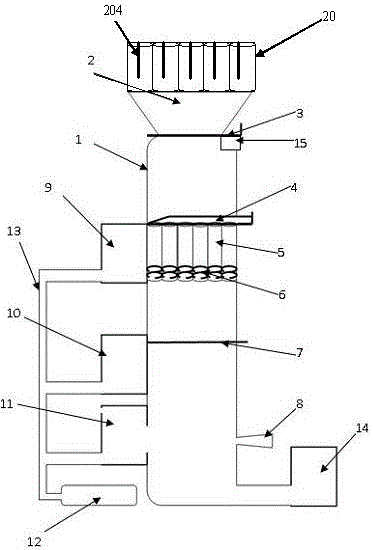

[0032] Corn comprehensive treatment device, including corn kernel removal device and by-product recovery and reuse device.

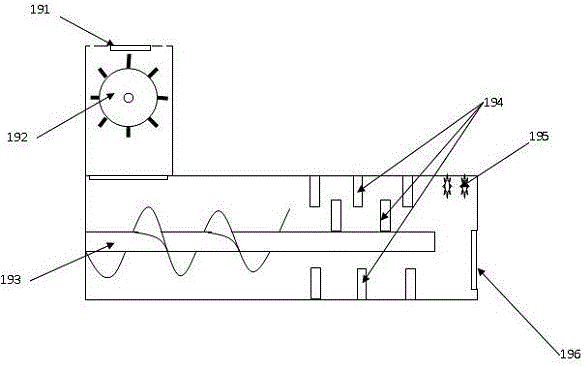

[0033] The corn kernel removing device includes a shell, a pretreatment device, a feeding device, a husk separating device, a threshing device, an impurity removing device and a control device.

[0034] The by-product recovery and reuse device includes a crushing device, a compression device and a by-product storage device.

[0035] The casing is arranged vertically.

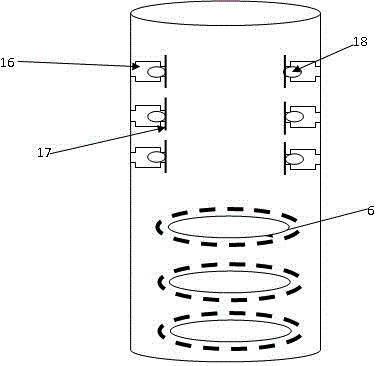

[0036] The pretreatment device is arranged on the top of the feeding device, and includes a push rod and an outer turning husk roller, and the outer turning husk roller includes a spring connected to the shell, a roller shaft, and a rotatable wheel arranged on the roller shaft. Rubber rollers and a telescopic stainless steel frame arranged in the middle of the spring and connected to the casing and the roller shaft.

[0037] The bract separation device comprises a bract cutter, a bract c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com