Combined type locker

A locker and combined technology, which is applied in the field of machinery, can solve the problems of inconvenient use, limited storage space, and being eaten by insects, etc., and achieve the effect of diversified adjustment methods, wide adjustment range, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

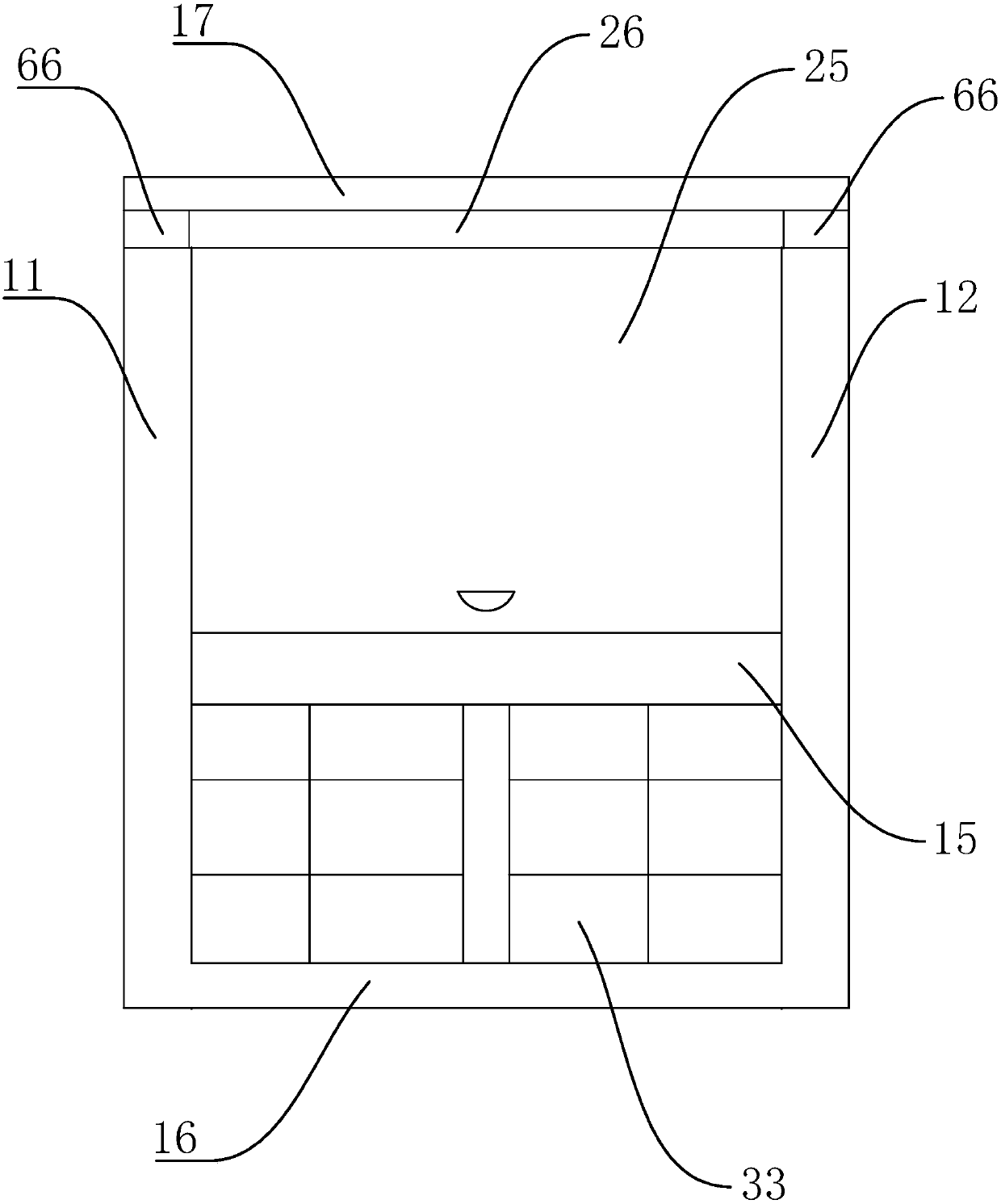

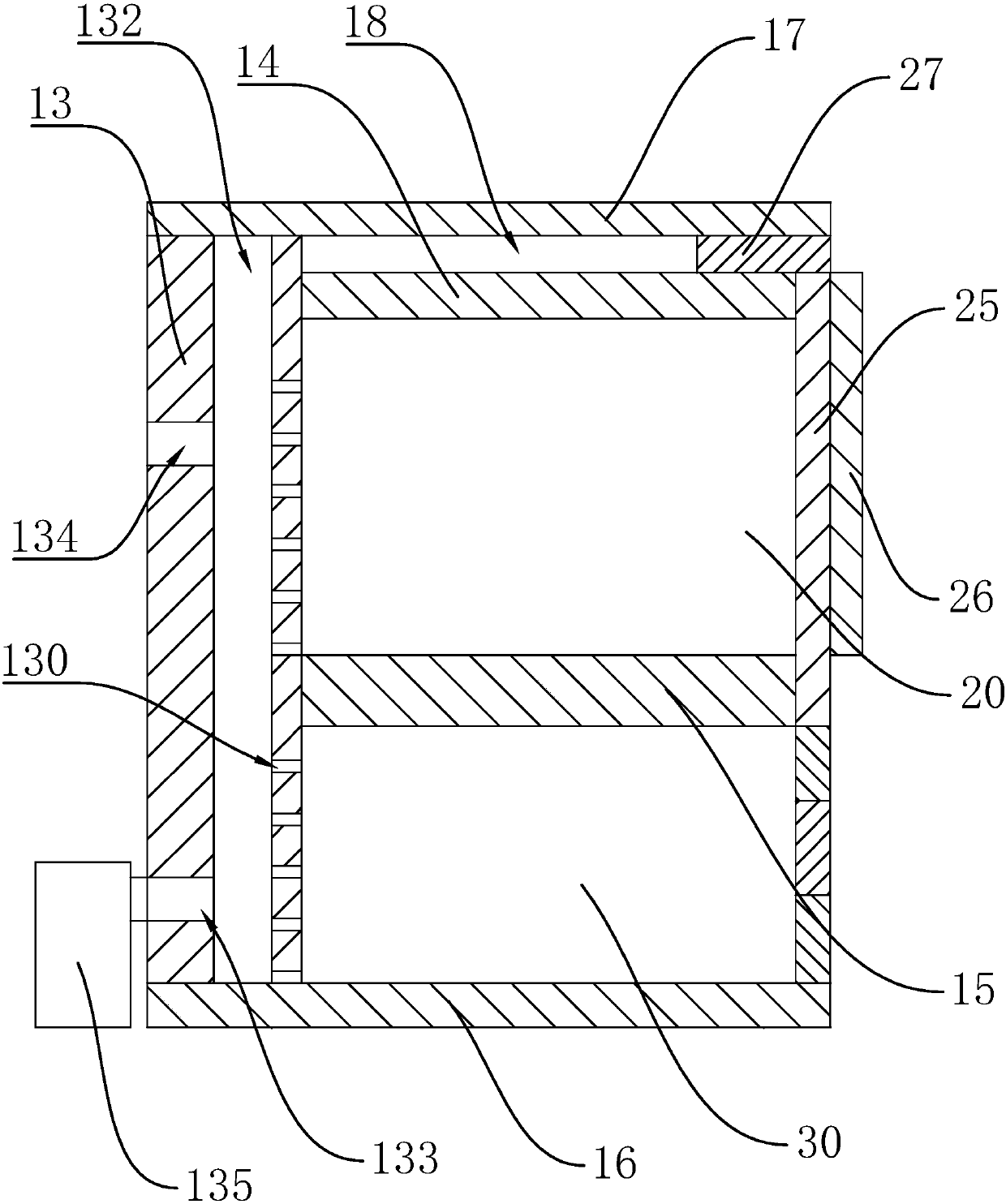

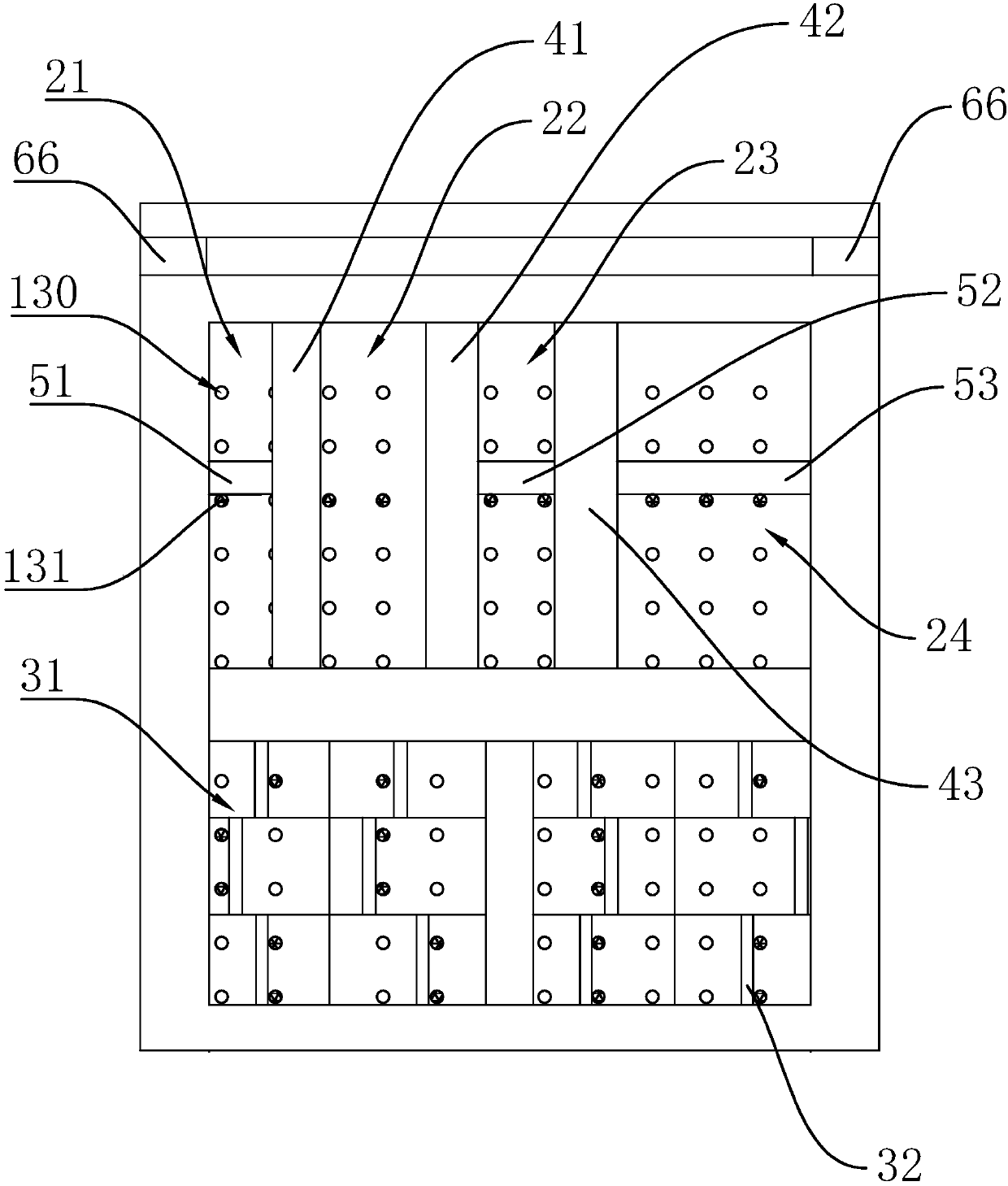

[0031] Such as Figure 1 to Figure 7 As shown, the present invention provides a combined locker, comprising a cabinet body composed of cabinet panels, the cabinet panels include a left cabinet panel 11, a right cabinet panel 12, a rear cabinet panel 13, an upper cabinet panel 14, and a middle panel 15 And the lower cabinet 16; The back cabinet 13, the middle board 15 and the lower cabinet 16 surround the lower cabinet 30 for placing documents; A chute 66 is provided, and the top plate 17 and the upper cabinet board 14 form a whiteboard cavity 18 for accommodating the whiteboard 26, which is rotatably connected to the upper cabinet body 20; the locker also includes an upper cabinet door for opening and closing the upper ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com