Demister

A technology of mist eliminator and mist eliminator, which is applied in chemical instruments and methods, combined devices, gas treatment, etc., can solve the problem that micron-scale and sub-microscopic particles cannot be captured, the separation efficiency of baffle plate mist eliminator is limited, and the type of A single baffle defogger and other problems can achieve the effect of intelligent defogging, increasing pressure loss and reducing possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

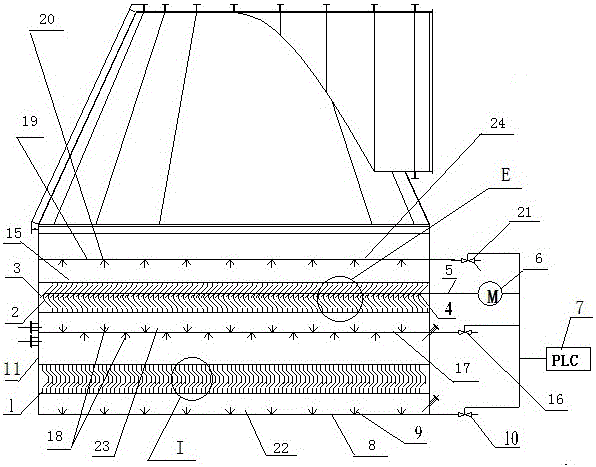

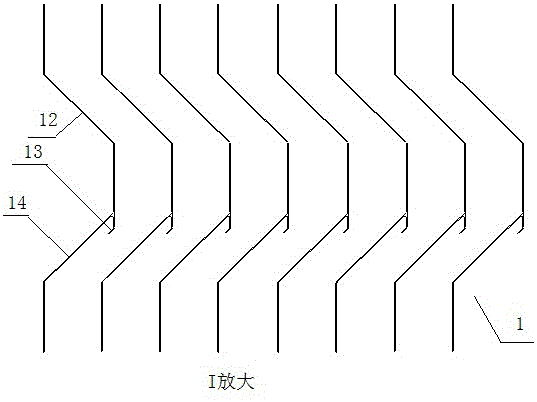

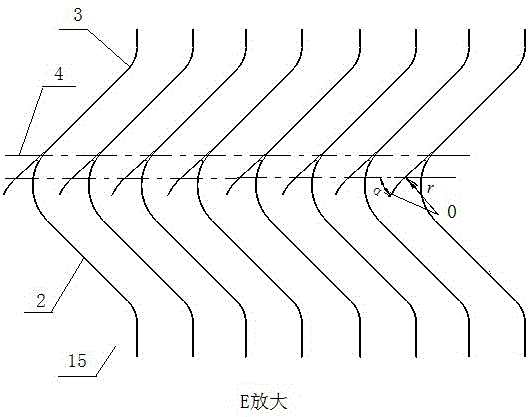

[0024] Such as figure 1 As shown, a demister includes a demister body 11, and a first high-pressure flushing device 22, a hook baffle demister 1, and a second high-pressure flushing device are sequentially arranged in the demister body 11 from bottom to top. The device 23, the hook plate adjustable corrugated plate defogging device 15 and the third high-pressure flushing device 24, the programmable controller PLC is connected with the first control valve 10 of the first high-pressure flushing device 22 and the second high-pressure flushing device 23 respectively. The control valve 16 is electrically connected to the third control valve 21 of the third high-pressure flushing device 24 , and the programmable logic controller (PLC) is electrically connected to the drive motor 6 of the corrugated plate defogging device 15 with adjustable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com