A cleaning system for photovoltaic power station cleaning robot

A cleaning robot and cleaning system technology, which is applied in the field of cleaning systems, can solve the problems of non-interchangeable and single-use robots, and achieve the effect of ensuring versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

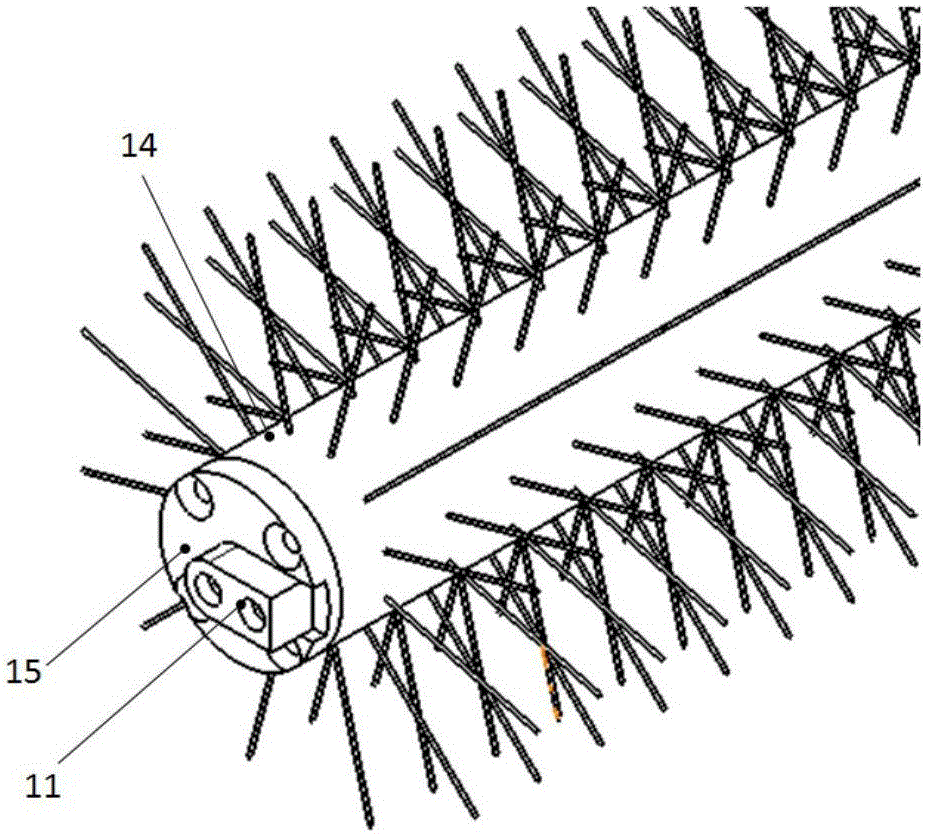

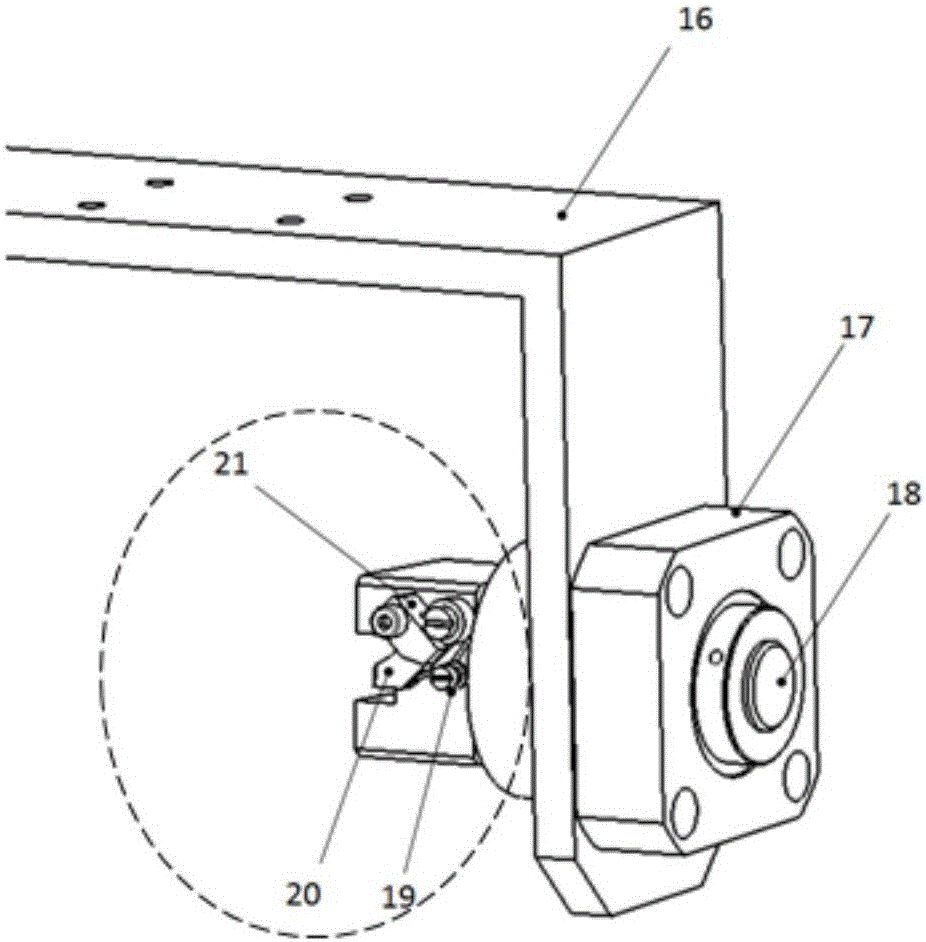

[0022] The cleaning robot of the present embodiment installs the rolling brush assembly first, and the structure of the rolling brush assembly is as follows: figure 2 shown. The left and right ends of the roller brush body 14 are connected with a roller brush coupling 15 and a projection 11 with screws, wherein the projection 11 is inserted into the groove at one end of the cleaning main shaft 18 . On the side that cleaning main shaft 18 has groove that end, be fixed with torsion spring 19, driving lever 20 and limit block 21 with screw. The torsion spring 19 presses the driving rod 20 to make it in the working position, and at the same time, the limit block 21 defines the upper limit position of the driving rod 20 . When performing cleaning tasks, the motor drives the cleaning main shaft 18 installed in the bearing assembly 17 to rotate, and drives the torsion spring 19, driving lever 20 and limit block 21 installed on the side of one end of the cleaning main shaft 18 to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com