Four-shaft linked horizontal numerical control grinding machine and utilization method thereof

A four-axis linkage, CNC grinding machine technology, applied in the direction of grinding machine, grinding bed, grinding machine parts, etc., can solve the problems of processing technology, production efficiency can not be improved, tedious and complicated debugging work, change is erratic, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

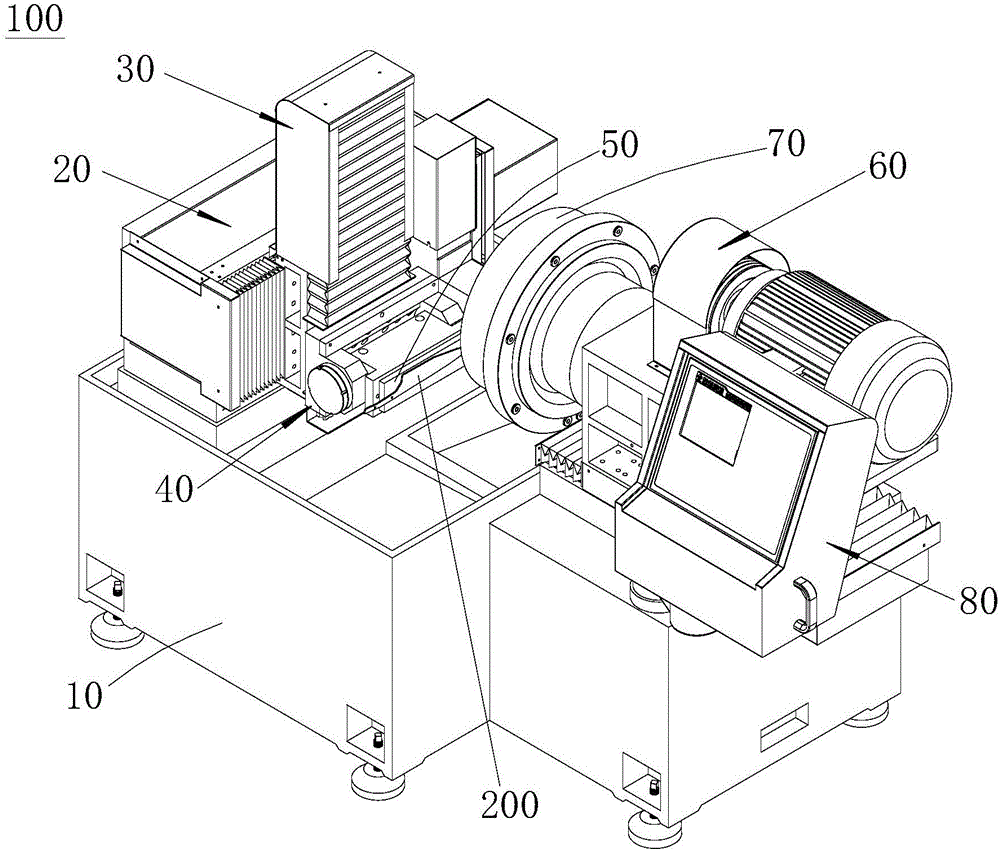

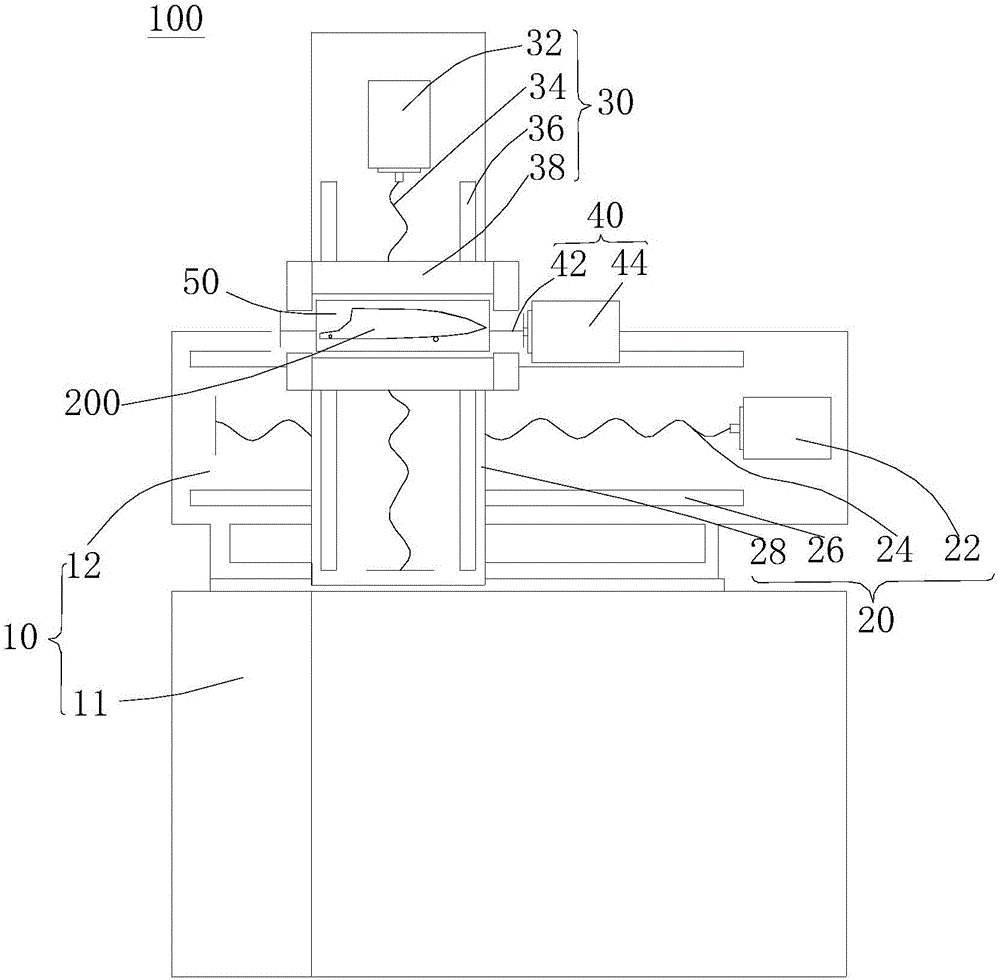

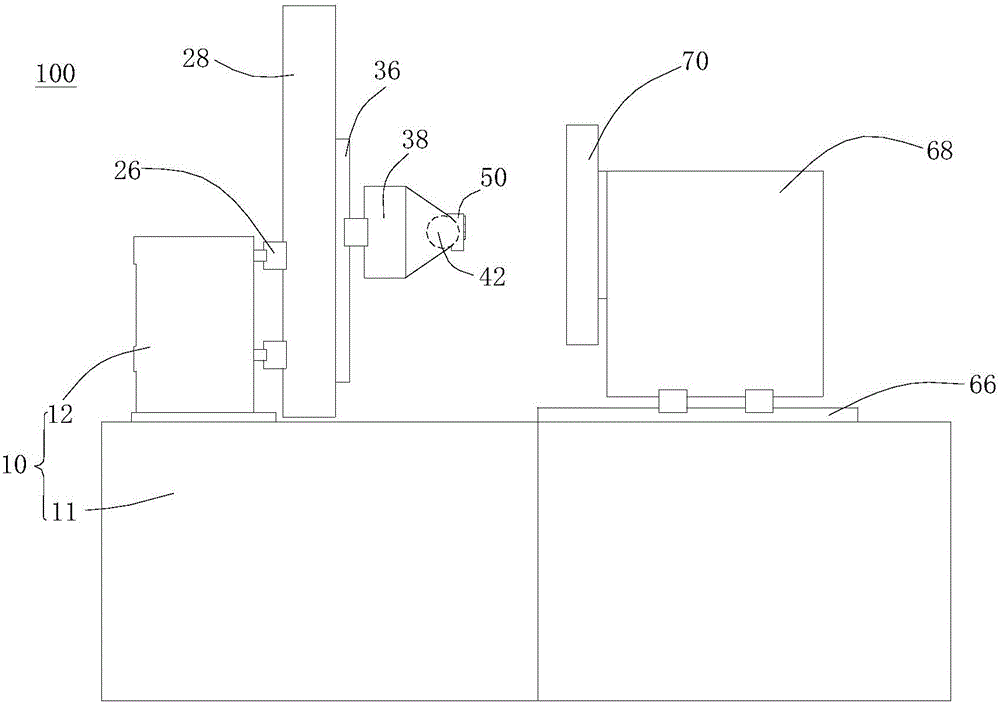

[0021] see Figure 1 to Figure 4 , a four-axis linkage horizontal CNC grinding machine 100 is used to process a workpiece 200, the four-axis linkage horizontal CNC grinding machine 100 includes a base 10, a first moving mechanism 20, a second moving mechanism 30, a rotating mechanism 40. A workbench 50, a third moving mechanism 60, a grinding wheel 70 and a numerical control device 80.

[0022] The base 10 includes a body 11 and a supporting frame 12 . The support frame 12 is fixed on the body 11 . The first moving mechanism 20 includes a first driving element 22 , a first transmission element 24 , two first sliding rails 26 and a first sliding plate 28 . In one embodiment, the first driving member 22 is a motor, and the first transmission member 24 is a threaded rod.

[0023] The second moving mechanism 30 includes a second driving member 32 , a second transmission member 34 , two second sliding rails 36 and a second sliding plate 38 . In one embodiment, the second drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com