Constant-pressure blank pressing mechanism

A technology of constant pressure and blank, applied in the field of constant pressure blank pressing mechanism, can solve the problems such as the pressure can not be too large, the hollow part of the blank is deformed, the wall thickness of the ceramic product is not easy to control, etc., to achieve high transmission efficiency, reduce The effect of the possibility of bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

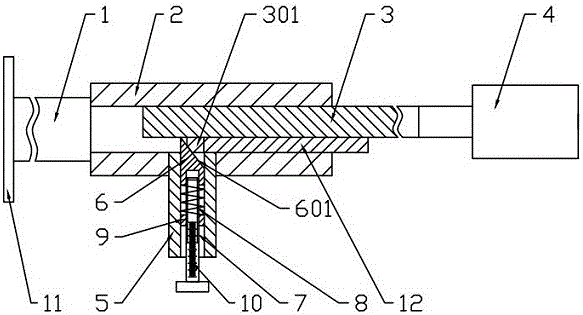

[0015] The reference signs in the accompanying drawings of the specification include: push rod 1, casing 2, power rod 3, ratchet 301, hydraulic cylinder 4, support 5, wedge 6, wedge surface 601, screw rod 7, spring 8, baffle 9. Scale 10, flange 11, block 12.

[0016] Embodiment The constant pressure blank pressing mechanism is basically as attached figure 1 Shown: including push rod 1 and bushing 2, push rod 1 and bushing 2 are coaxial, push rod 1 is fixed on bushing 2, power rod 3 is slidingly connected in bushing 2, and power rod 3 is far away from bushing 2 One end of the hydraulic cylinder 4 is provided, the power rod 3 is provided with a ratchet 301, and a through hole is opened on the casing 2 along the direction perpendicular to the axis of the casing 2, and a support 5 is fixed in the through hole, and the support 5 is Cylindrical, the support 5 is coaxial with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com