Zipper type paper box enabling tearing edge to be smooth and manufacturing method of zipper type paper box

A carton and zipper technology, which is applied in the field of zipper cartons and its manufacture, can solve the problems of not paying attention to the tearable zipper structure, not providing fresh-keeping and moisture-proof components, not paying attention to flatness, strength, aesthetics and durability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Boards suitable for making paper packaging boxes can be obtained from commercial or other sources, and laser perforation technology is used to make two rows of holes arranged in a straight line on the paper board in a straight line, as the part to be torn off of the carton.

[0036] Here, without limitation, the laser perforation process may be an existing industrialized laser perforation process, or a laser processing process disclosed in other documents (for example, Chinese patent document CN103274092A). During the processing, the distance between two rows of holes is 10 mm, the diameter of each hole is set to 1.0 mm, and the hole spacing is set to 0.5 mm; the holes are circular.

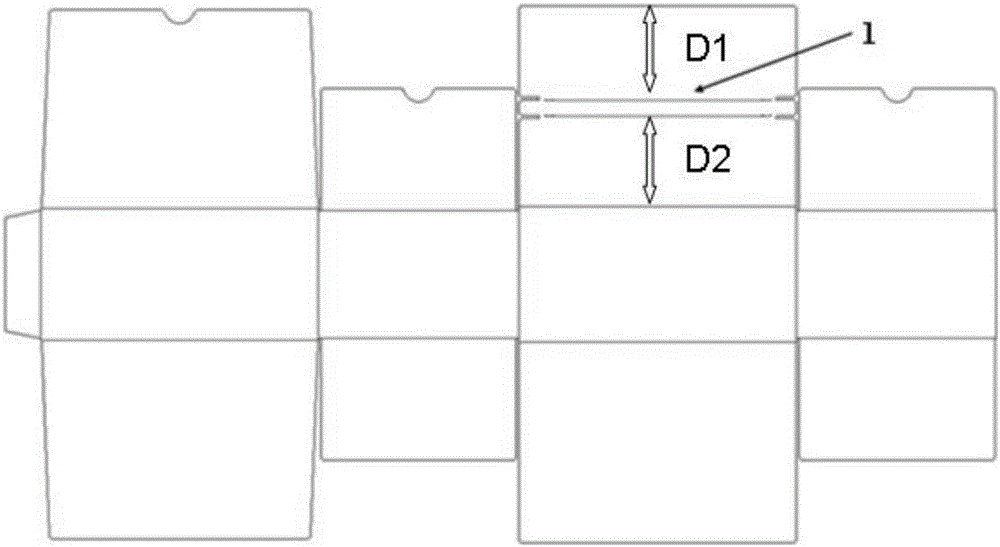

[0037] The prepared carton before folding is in figure 1 visible in . It can be seen from the figure that the position 1 marked by the two thinner lines indicated by the arrow represents the prepared carton. figure 1 Only one closely-arranged hole (that is, the part to be torn) that has ...

Embodiment 2

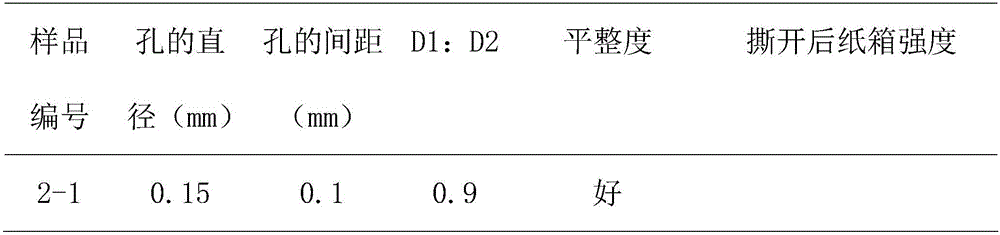

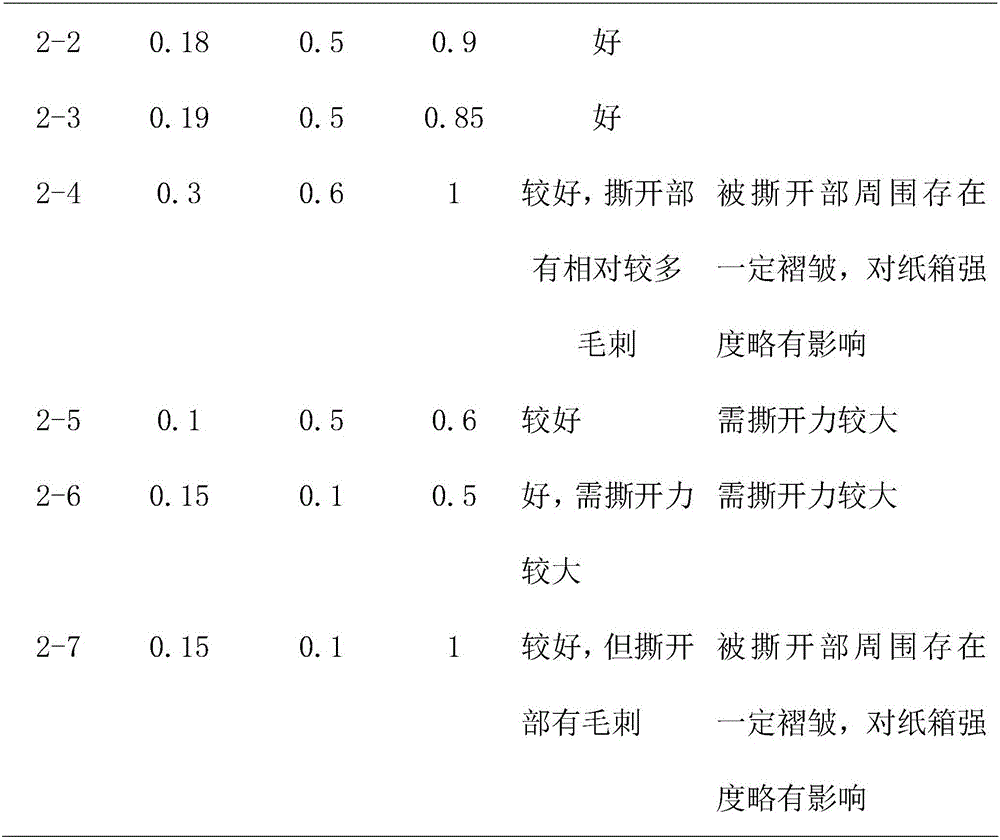

[0041] Adopt similar preparation process and steps as in Example 1, but the difference is that for the hole diameter, the spacing between adjacent holes and the width (D1) of the discarded part after tearing and the height (D2) of the carton The preferred scheme has been implemented.

[0042]Specifically, the inventors found through repeated research that although the size of the carton may vary according to the application, the hole diameter, the spacing between adjacent holes, and the discarded part are essential for the flatness and strength of the torn carton A better technical solution can be obtained by setting the ratio of the width and height of the carton. Without limitation, for example, in a specific preparation process, when the diameter of the holes is 0.15-0.19mm, and the spacing of the holes is 0.1-0.5mm, better packaging box flatness after tearing is obtained; and in the tearing process Among them, the tearing force used by the user is moderate, and the streng...

Embodiment 3

[0049] This embodiment uses a process similar to that of Embodiment 1, the difference is that this embodiment focuses on the composite structure and composition of the packaging carton.

[0050] In this embodiment, the sheet material of the paper packaging box is provided, the sheet material used (and the corresponding carton structure finally prepared) includes a face paper layer, a core paper layer and a protective layer; (optionally the face paper layer and The adhesive layer between the core paper layers) and the protective layer includes a strength protective layer, a waterproof penetration layer and an oil-proof layer, and the strength protection layer, the waterproof penetration layer and the oil-proof layer are arranged on the face paper layer or the oil-proof layer of the carton in sequence on top of the core paper layer. The strength protection layer can adopt such as metal mesh (such as steel wire mesh), fiber mesh, acrylic board; the waterproof layer can adopt alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com