Anti-corrosion structure of edge plate of oil storage tank and its construction method

A technology of edge plates and storage tanks, which is applied to the anti-corrosion structure of oil depot storage tank edge plates and its construction, can solve the problems of lack of performance characteristics, etc., achieve isolation of external water vapor and other corrosives, good external water vapor and other corrosives, and increase thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

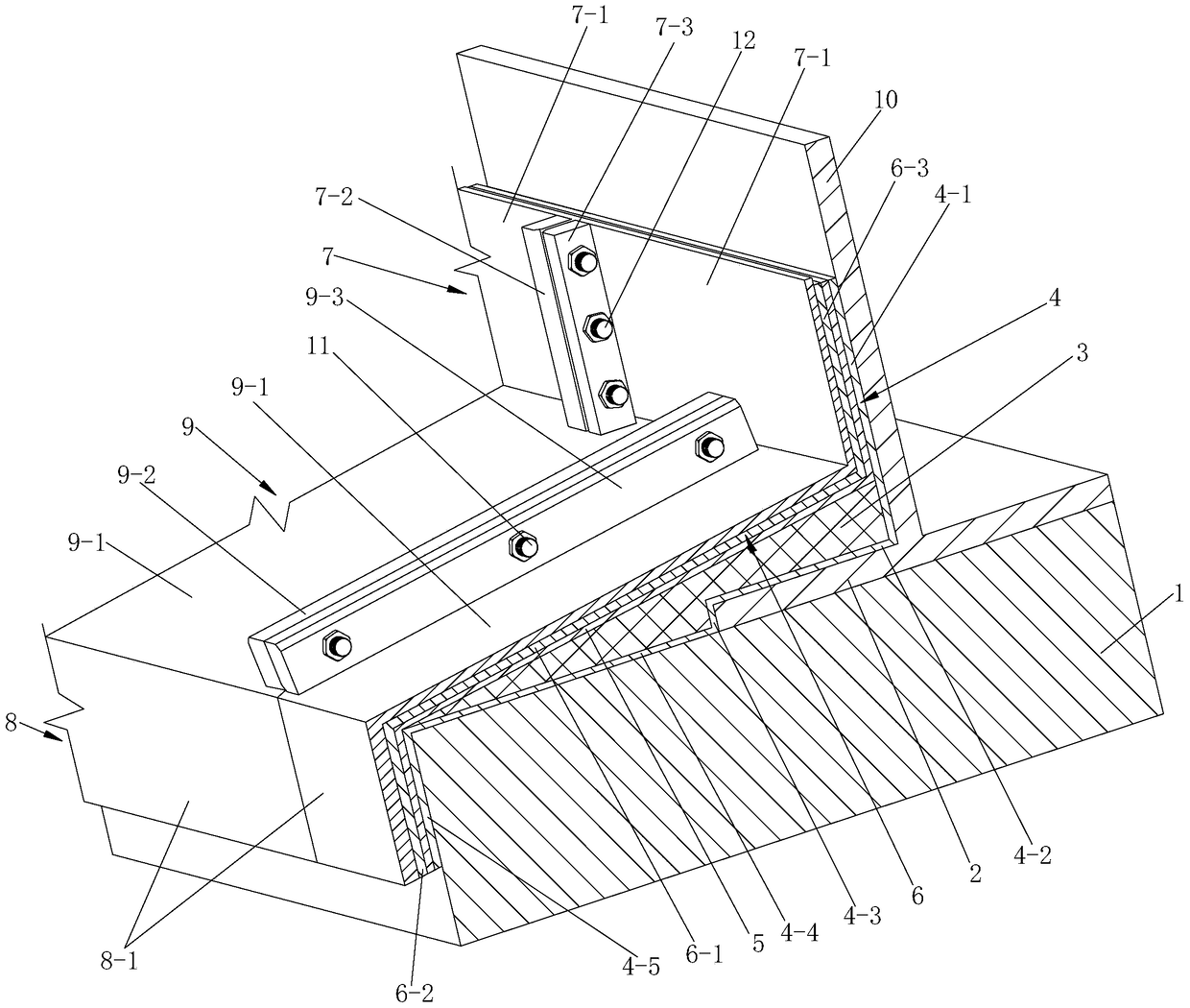

[0054] like figure 1 The shown anti-corrosion structure for the edge plate of an oil depot storage tank includes an anti-corrosion primer layer 4, a flexible slope-seeking layer 3 arranged on the outside of the anti-corrosion primer layer 4, and a first slope-seeking layer arranged on the outside of the flexible slope-seeking layer 3. The anti-corrosion oil tape layer 5 and the second anti-corrosion oil tape layer 6 covering the outside of the first anti-corrosion oil tape layer 5, and the anti-corrosion primer layer 4 includes a storage tank for covering at least part of the outer side of the tank wall plate 10 Wall plate anti-corrosion section 4-1, edge plate surface anti-corrosion section 4-2 used to cover the upper surface of edge plate 2, edge plate outer side anti-corrosion section 4-3 used to cover the outer side of edge plate 2, used to cover storage The anti-corrosion section 4-4 on the upper surface of the tank foundation 1 and the anti-corrosion section 4-5 on the o...

Embodiment 2

[0088] like Image 6 As shown, the difference between this embodiment and Embodiment 1 is only that: the outer side of the first anti-corrosion oil tape layer 5 is also coated with an anti-corrosion primer for bonding with the second anti-corrosion oil tape layer 6 to strengthen Layer 13.

[0089]In this embodiment, when the construction temperature is -20°C to 15°C, the anti-corrosion primer reinforcement layer 13 is added in order to enhance the bonding strength of the first anti-corrosion oil tape layer 5 and the second anti-corrosion oil tape layer 6 . The anti-corrosion primer reinforcement layer 13 can effectively improve the bonding strength of the first anti-corrosion oil tape layer 5 and the second anti-corrosion oil tape layer 6 .

[0090] In the present embodiment, the anti-corrosion primer reinforcement layer 13 is made of petrolatum anti-corrosion primer, and the petrolatum anti-corrosion primer adopts the model STAC oil-based petrolatum primer produced by Centra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com