Conductive enhanced PC and PBT resin composition and preparation method thereof

A technology of PBT resin and conductive enhancement, which is applied in the field of polymer material processing, can solve the problems of poor impact resistance, cost increase, and impact performance decline of composite materials, and achieve good electrical conductivity and impact performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

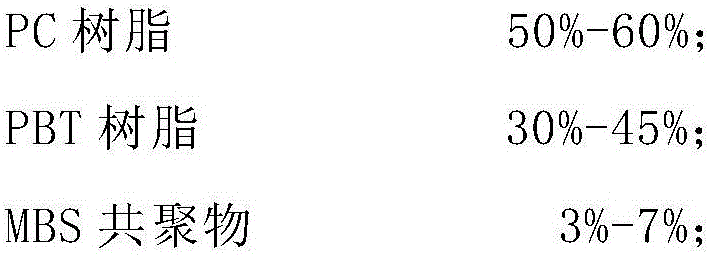

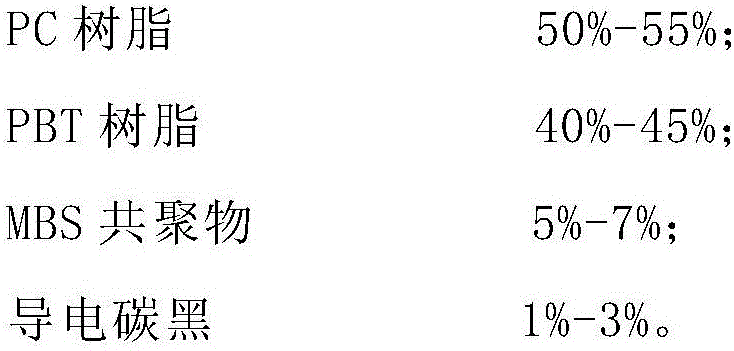

[0027] The raw materials used are:

[0028] PC resin, the weight average molecular weight is 3.0×10 4 g / mol;

[0029] PBT resin, intrinsic viscosity is 1.0dl / g;

[0030] MBS copolymer, particle diameter is 300nm, butadiene weight percentage is 60%;

[0031] Surface-modified conductive carbon black with an average size of about 100nm and -COOH on the surface; for example, Ketjenblack EC-600JD produced by Akzo Nobel.

[0032] Each component was weighed according to the weight percentage shown in Table 1, and then the thermoplastic resin composition was prepared by the following method:

[0033] Step 1, taking each component according to parts by weight;

[0034] Step 2, fully mixing PBT resin, MBS copolymer and conductive carbon black in a high-speed mixer for 10 minutes to obtain a mixture;

[0035] In step 3, the PC resin enters from the first feed port of the twin-screw extruder, and the premix obtained in step 2 enters from the second feed port, and is melted and extrud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap