Cyanate resin base composite material and preparation method thereof

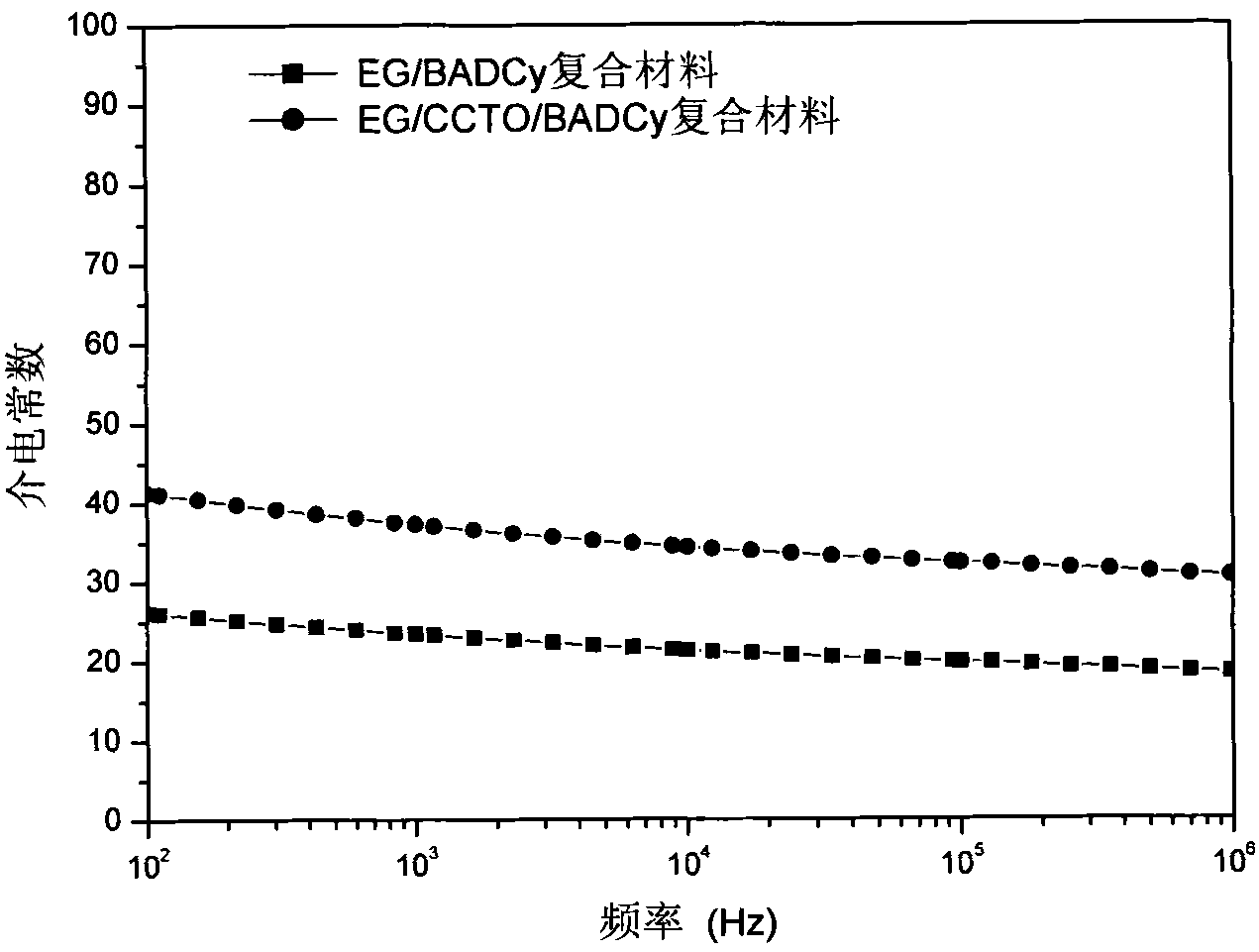

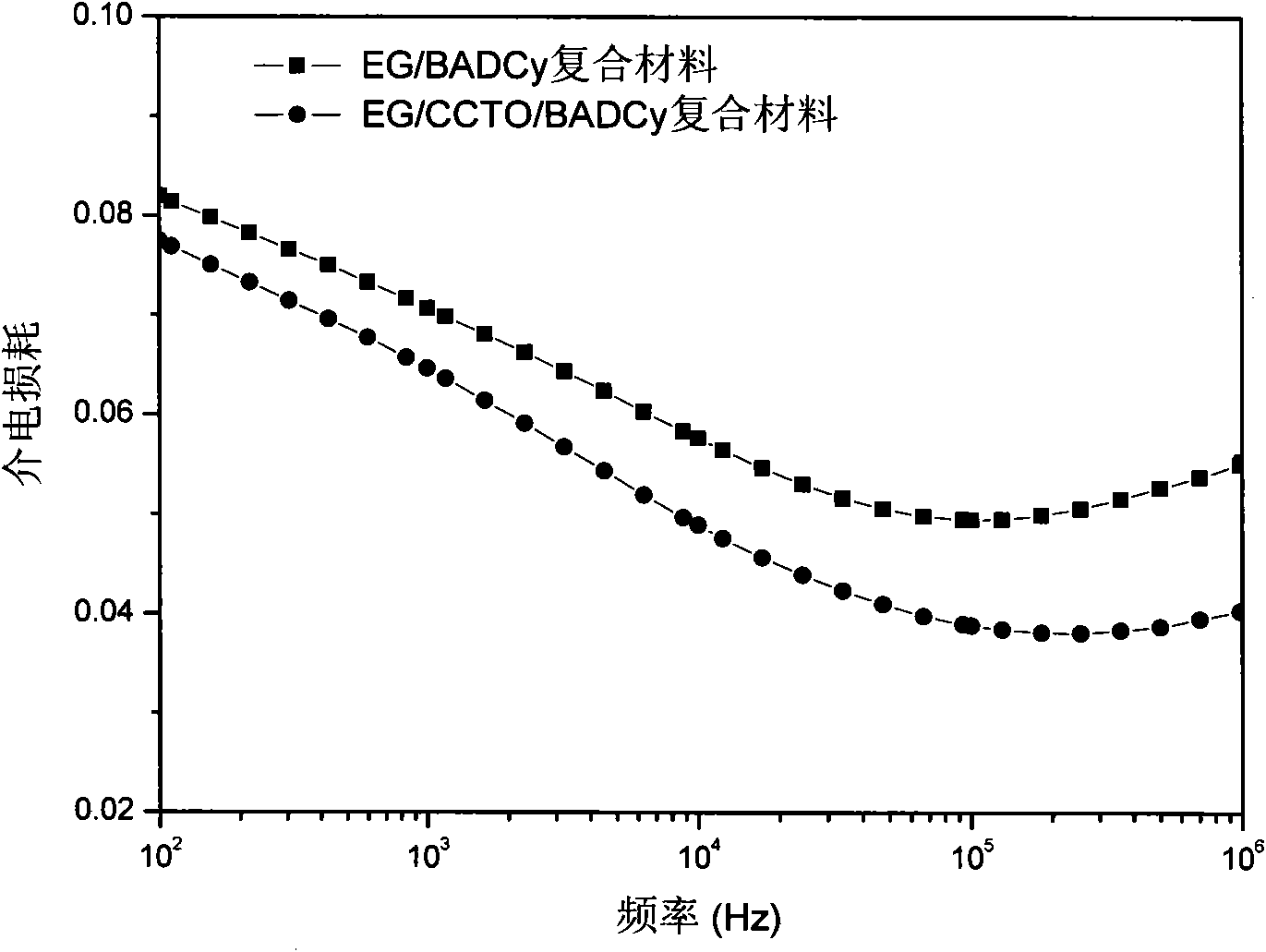

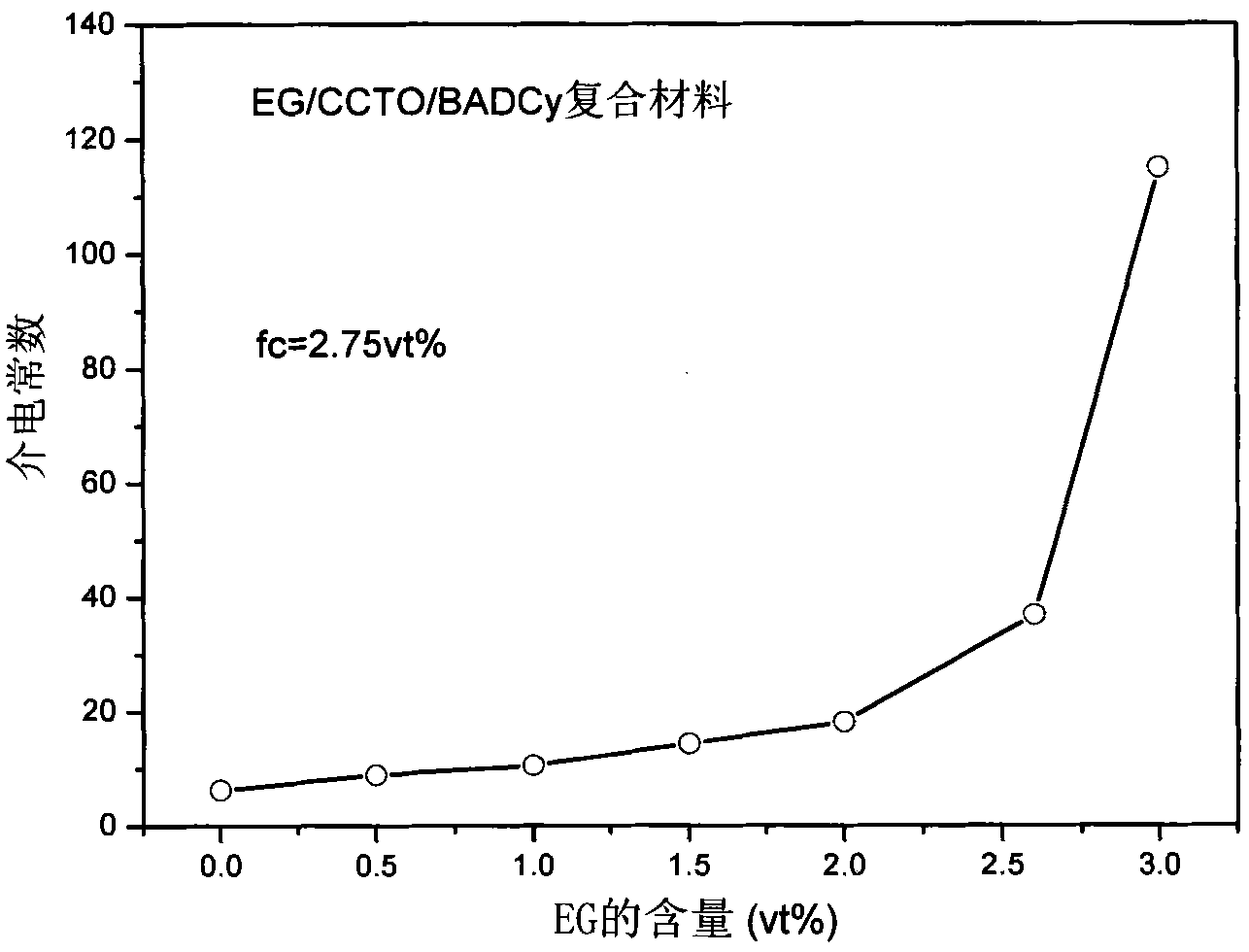

A technology of cyanate resin and composite materials, which is applied in the fields of cyanate resin-based composite materials, high dielectric constant cyanate resin-based composite materials and their preparation, and can solve the problems of high dielectric loss of composite materials and composite materials. Poor heat resistance and other problems, to achieve the effect of improving dielectric properties, promoting dispersion, and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Copper calcium titanate with a particle size of 1 μm was kept at 120° C. for 4 hours to obtain dried copper calcium titanate. Pour the dried copper calcium titanate into an ethanol aqueous solution of γ-aminopropyltriethoxysilane (KH-550) at 40°C (the mass of KH-550 is 1% of the mass of copper calcium titanate, KH-550: The mass ratio of ethanol: water is 1: 20: 2), stirred evenly with a high-speed homogeneous mixer, left to air at room temperature for 8 hours, and baked at 90°C for 2 hours to obtain surface-treated copper calcium titanate, which is denoted as CCTO.

[0032] Put the expandable graphite (80 mesh) into the porcelain crucible, expand it rapidly at a high temperature of 900°C, take it out of the high-temperature furnace when it no longer expands (about 20s), and then put the expanded graphite in acetone solvent Sonicate for 2 hours, leave in the air at room temperature for 12 hours, and dry at 90°C for 2 hours to obtain expanded graphite flakes (diameter 20...

Embodiment 2

[0041] Copper calcium titanate with a particle size of 2 μm was kept at 120° C. for 4 hours to obtain dried copper calcium titanate. Pour the dried copper calcium titanate into an ethanol aqueous solution of γ-aminopropyltriethoxysilane (KH-550) at 40°C (the mass of KH-550 is 1% of the mass of copper calcium titanate, KH-550: Ethanol: water = 1: 20: 2, mass ratio), stirred evenly with a high-speed homogeneous mixer, left to air at room temperature for 8 hours, and baked at 90°C for 2 hours to obtain surface-treated calcium copper titanate, which is denoted as CCTO.

[0042] Put the expandable graphite (100 mesh) into a porcelain crucible, expand it rapidly at a high temperature of 700°C, take it out of the high-temperature furnace when it no longer expands (about 60s), and then put the expanded graphite in acetone solvent Sonicate for 4 hours, leave in the air at room temperature for 12 hours, and dry at 90°C for 2 hours to obtain expanded graphite flakes (diameter 10-40 μm, ...

Embodiment 3

[0055] Copper calcium titanate with a particle size of 2 μm was kept at 120° C. for 4 hours to obtain dried copper calcium titanate. Pour the dried copper calcium titanate into the ethanol aqueous solution of γ-aminopropyltriethoxysilane (KH-550) at 40°C (the quality of KH-550 is 1% of the mass of copper calcium titanate, KH-550 : ethanol: the mass ratio of water is 1: 20: 2), stirred evenly with a high-speed homogeneous mixer, left to air at room temperature for 8 hours, and baked at 90°C for 2 hours to obtain surface-treated copper calcium titanate, record for the CCTO.

[0056] Put the expandable graphite (80 mesh) into the porcelain crucible, expand it rapidly at a high temperature of 900°C, take it out of the high temperature furnace when it no longer expands (about 20s), and then put the expanded graphite in acetone solvent Sonicate for 4 hours, leave in the air at room temperature for 12 hours, and dry at 90°C for 2 hours to obtain expanded graphite flakes (diameter 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com