Remelting refining slag and method for applying remelting refining slag to electroslag remelting of high-Al and high-Ti alloy steel

An electroslag remelting and electroslag remelting furnace technology, applied in the field of electrometallurgy, can solve the problems of large deviation of the head and tail of Ti steel ingots, unsuitable electroslag remelting, uneven collection, etc. The effect of TiO2 transferring oxygen supply and improving activity coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

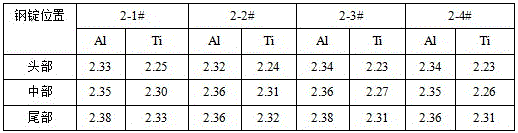

[0027] Example 1 Electroslag remelting GH37 alloy

[0028] The GH37 alloy is used as the consumable electrode, the size of the consumable electrode blank is ∮450mm, and the mold size is ∮600mm.

[0029] Select remelting and refining slag of the following components by weight: CaF 2 50 parts, Al 2o 3 20 parts, CaO 15 parts, TiO 2 10 parts and MgO 5 parts. Among them, CaF 2 、Al 2 o 3 , CaO, TiO 2 and SiO in MgO 2 The mass content of all ≤ 1.0%.

[0030] The following method is used to carry out electroslag remelting of GH37 alloy, including the following steps:

[0031] 1) Bake the above remelted refining slag at 800°C for 10 hours,

[0032] 2) Use the above GH37 alloy as the consumable electrode, assemble the electroslag remelting furnace, add the deoxidizer and the remelting refining slag baked in step 1) to the special slag melting furnace for melting, and the slag is completely melted Pour it into the remelting furnace; wherein, the added amount of the remelti...

Embodiment 2

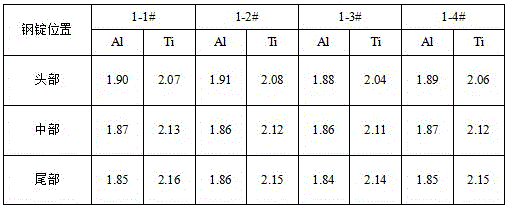

[0037] Embodiment 2 Electroslag remelting of GH35 alloy

[0038] The GH35 alloy is used as the consumable electrode, the size of the consumable electrode blank is ∮490mm, and the mold size is ∮650mm.

[0039] Select remelting and refining slag of the following components by weight: CaF 2 45 parts, Al 2 o 3 20 parts, CaO 20 parts, TiO 2 8 parts and MgO 7 parts. Among them, CaF 2 、Al 2 o 3 , CaO, TiO 2 and SiO in MgO 2 The mass content of all ≤ 1.0%.

[0040] The following method is used to carry out electroslag remelting of GH35 alloy, including the following steps:

[0041] 1) Bake the above remelted refining slag at 650°C for 13 hours,

[0042] 2) Use the above GH35 alloy as the consumable electrode, assemble the electroslag remelting furnace, add the deoxidizer and the remelting refining slag baked in step 1) to the special slag melting furnace for melting, and the slag is completely melted Pour it into the remelting furnace; wherein, the added amount of the r...

Embodiment 3

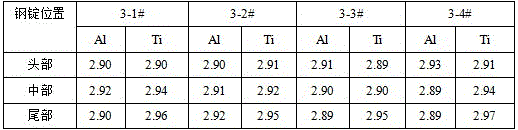

[0047] Example 3 Electroslag remelting of GH500 alloy

[0048] GH500 alloy is used as the consumable electrode, the size of the consumable electrode blank is ∮525mm, and the mold size is ∮700mm.

[0049] Select remelting and refining slag of the following components by weight: CaF 2 48 copies, Al 2 o 3 19 parts, CaO 18 parts, TiO 2 9 parts and MgO 6 parts. Among them, CaF 2 、Al 2 o 3 , CaO, TiO 2 and SiO in MgO 2 The mass content of all ≤ 1.0%.

[0050] The electroslag remelting of the GH500 alloy is carried out by the following method, including the following steps:

[0051] 1) Bake the above remelted refining slag at 700°C for 11 hours,

[0052] 2) With the above-mentioned GH500 alloy as the consumable electrode, assemble the electroslag remelting furnace. Add the deoxidizer and the remelted refining slag baked in step 1) into a special slag melting furnace for melting, and pour the molten slag into the remelting furnace after all the slag is melted; wherein, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com