Droplet transfer control device and control method for gas shielded welding based on droplet resonance principle

A technology of gas shielded welding and droplet transfer, applied in the direction of manufacturing tools, welding equipment, welding accessories, etc., to achieve the effects of shortening the heating time, preventing short-circuit transition, and shortening the heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

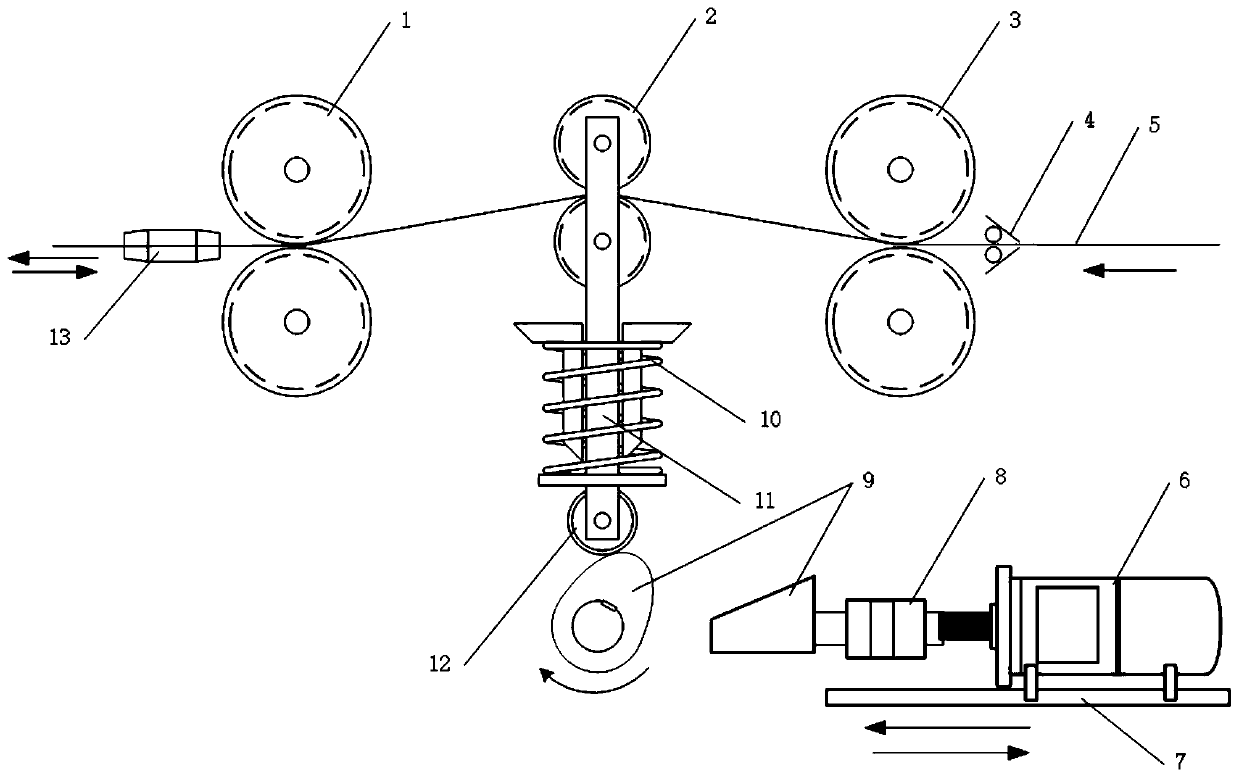

[0017] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment, the gas shielded welding droplet transfer control device based on the principle of droplet resonance in this embodiment includes a first guide wire pair wheel 1, a second guide wire pair wheel 2, a third guide wire pair wheel 3, a cam Guide wheel mechanism, cam drive mechanism and contact tip 13, the first wire pair wheel 1, the second guide wire pair wheel 2, and the third guide wire pair wheel 3 are arranged in sequence from left to right, and the second guide wire pair wheel 2 is installed On the upper end of the cam guide wheel mechanism, the lower end of the cam guide wheel mechanism is connected with the cam driving mechanism, and the welding wire 5 passes through three pairs of guide wire pairs of wheels from right to left and is connected with the contact tip 13 one by one.

specific Embodiment approach 2

[0018] Specific implementation mode two: combination Figure 1 to Figure 6 Describe this embodiment, the cam guide wheel mechanism of the gas shielded welding droplet transfer control device based on the droplet resonance principle in this embodiment includes a return spring 10, a cam push rod 11 and a cam guide wheel 12, and the upper end of the cam push rod 11 It is connected with the second guide wire pair wheel 2, the lower end of the cam ejector rod 11 is connected with the cam guide wheel 12, the return spring 10 is set on the cam ejector rod 11, and the return spring 10 is located between the second guide wire pair wheel 2 and the cam guide wheel Between 12. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination Figure 1 to Figure 6 Describe this embodiment, the cam driving mechanism of the gas shielded welding droplet transfer control device based on the droplet resonance principle in this embodiment includes a high-speed servo motor 6, a slide rail 7, a shaft coupling 8 and a variable-diameter cam 9, and the high-speed servo The motor 6 is installed on the slide rail 7, and the high-speed servo motor 6 can move linearly along the slide rail 7. The rotating shaft of the high-speed servo motor 6 is connected with the variable-diameter cam 9 through the shaft coupling 8, and the wheel rim of the variable-diameter cam 9 is connected to the cam The guide wheel 12 contacts. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com