A multi-component alloy co-infiltration treatment method with sufficient mixing and contact

A technology of multi-component alloy co-infiltration and treatment method, which is applied in the field of fully mixed and contacted multi-component alloy co-infiltration treatment. Alloy co-infiltration treatment unevenness and other problems, to avoid anti-corrosion weak position, reduce wear and deformation, good temperature resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

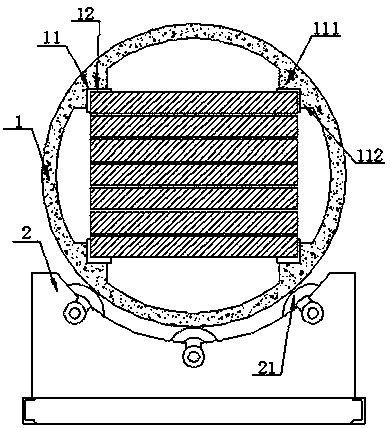

[0016] refer to figure 1 , figure 1 It is a schematic diagram of the structure of the rotary heating tank used in the specific embodiment of the present invention. The inner wall of the rotary heating tank 1 is provided with four sets of fixed clamping protrusions 11, and each set of fixed clamping protrusions consists of a horizontal limit bump 111 and a The vertical limit protrusion 112 is formed; the bottom of the rotating heating tank 1 is provided with a heating tank rotating car 2 for moving and driving the rotating heating tank 1 to rotate, and the heating tank rotating car is provided with a rotating support roller 21, and the rotating heating tank 1 is placed On rotating support rollers 21.

[0017] A multi-element alloy co-infiltration treatment method for fully mixed contact, comprising the following steps:

[0018] Plate cleaning: Put the metal plate that needs multi-component alloy co-infiltration treatment into the aqueous solution containing surfactant for che...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com