Cross-linked polyethylene insulated multi-core coaxial power cable

A cross-linked polyethylene and power cable technology, applied in the direction of insulated cables, coaxial cables, insulated conductors, etc., can solve the problems of cable electrical performance degradation, easy displacement of cores, easy core breakage, etc. Strong fire resistance, not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

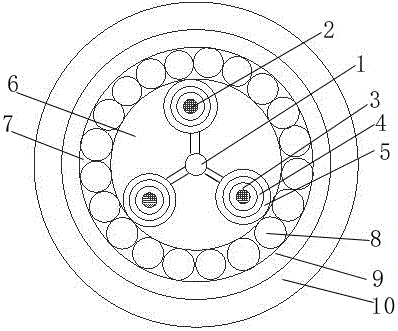

[0017] Such as figure 1 As shown, a cross-linked polyethylene insulated multi-core coaxial power cable according to the present invention includes a cable core, and PVC insulating material 6 is filled in the gap of the cable core; an outer conductor 7 is arranged outside the cable core, and the The outer conductor is made of multiple aluminum alloy monofilaments 8; the outer conductor is wrapped with a rock wool insulation layer 9 with a thickness of 0.48-0.9mm, and the rock wool insulation layer is extruded with a thickness of 1-2cm Aluminum sheath 10; the cable core is made of three insulated wire cores and a triangular reinforcing rib 1 connecting the three insulated wire cores; It consists of a 2mm cross-linked polyethylene insulating layer 4 and a shielding layer 5 with a thickness of 2-3mm extruded outside the cross-linked polyethylene insulating layer.

[0018] The triangular reinforcing rib 1 is composed of a circular insulating plastic core and three plastic brackets...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com