Replaceable surface layer combined sealing structure for concrete structural joint

A concrete structure and surface layer technology, which is applied in the field of structural joints and waterproof structures, can solve problems such as non-replacement, structural reinforcement conflicts, and high concrete thickness requirements, and achieve good waterproof effects, high connection strength, and strong adaptability to deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

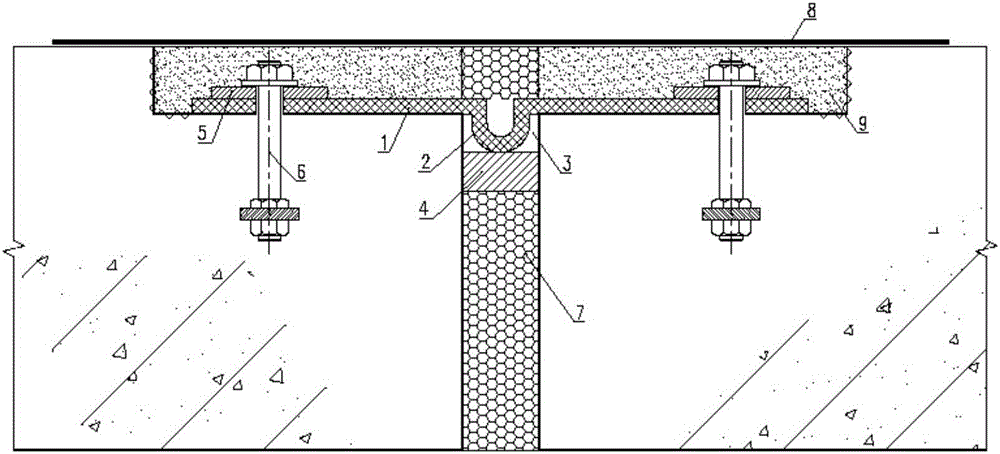

[0013] Such as figure 1 As shown, the replaceable surface layer combined water-stop structure for concrete structural joints of the present invention is grooved or reserved on both sides of the structural joint 3 on the concrete surface to form a water-stop groove, and the width of each side groove is 20-25cm , the groove depth is 4-5cm, the U-shaped rubber waterstop 1 is glued to the bottom of the waterstop by adhesive, and two waterstops on both sides of the structural joint 3 parallel to the structural joint are fixed by multiple sets of stainless steel bolts 6 The pressure plate 5 presses the U-shaped rubber waterstop 1 on the bottom surface of the waterstop, and the U-shaped part 2 of the U-shaped rubber waterstop 1 is inserted into the structural split 3, and the gap in the structural split Inject a 2-4cm thick sealant 4 between the seam material 7 and the raised U-shaped part 2, fill the upper part of the U-shaped rubber waterstop 1 with elastic material 9, and fill the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap