Vertical concrete feeder for gate groove

A feeder and door slot technology, which is applied in construction, infrastructure engineering, etc., can solve the problems of difficult access for large cranes, potential safety hazards in construction, and high occupancy rate of large equipment, and achieves simple structure, convenient operation, and reduced labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

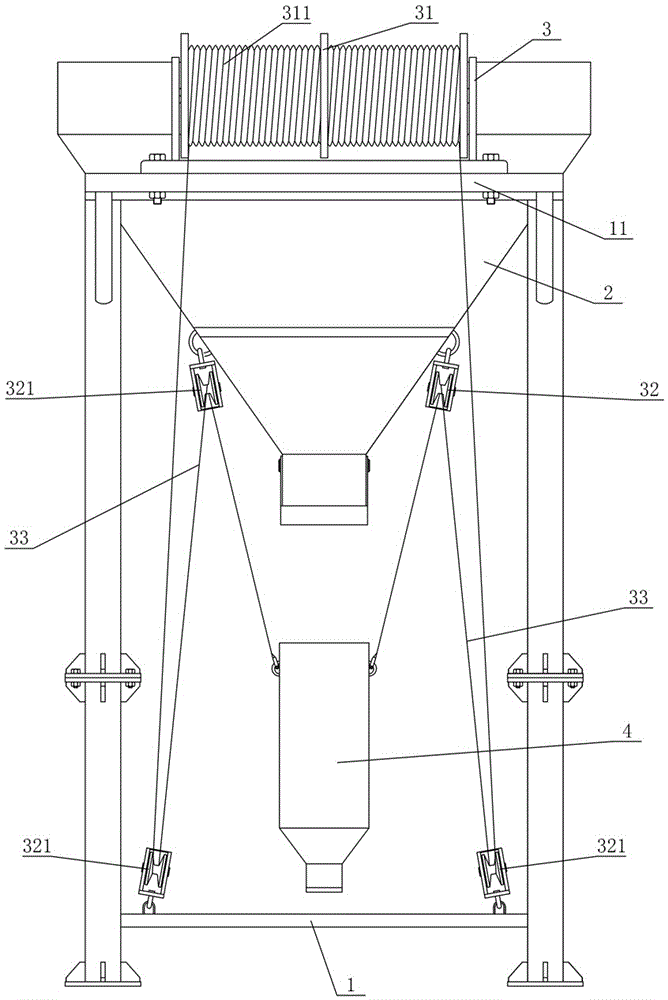

[0025] Figure 1 to Figure 6 Shown is an embodiment of the concrete vertical feeder for the door slot of the present invention, the feeder includes a frame 1, a material storage device 2 and a drive device 3 are installed on the frame 1, and a drive device and a drive device are arranged below the material storage device 2 3. A feeding device 4 that is detachably connected and is driven by the driving device 3 to move up and down. In the construction project, the concrete is sent into the storage device 2, the driving device 3 is started to lift the feeding device 4 to the vicinity of the lower position of the storage device 2, and then the storage device 2 is energized to open the lower end opening, so that the concrete in the storage device 2 falls. Put it into the feeding device 4 directly below it, then close the lower opening of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com