Split-flow valve type squatting pan

A squatting pan and diverter valve technology, applied in flushing equipment with water tanks, flushing toilets, water supply devices, etc., can solve the problem of high demand for cost space, and achieve the effects of preventing light pollution, reducing costs, and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

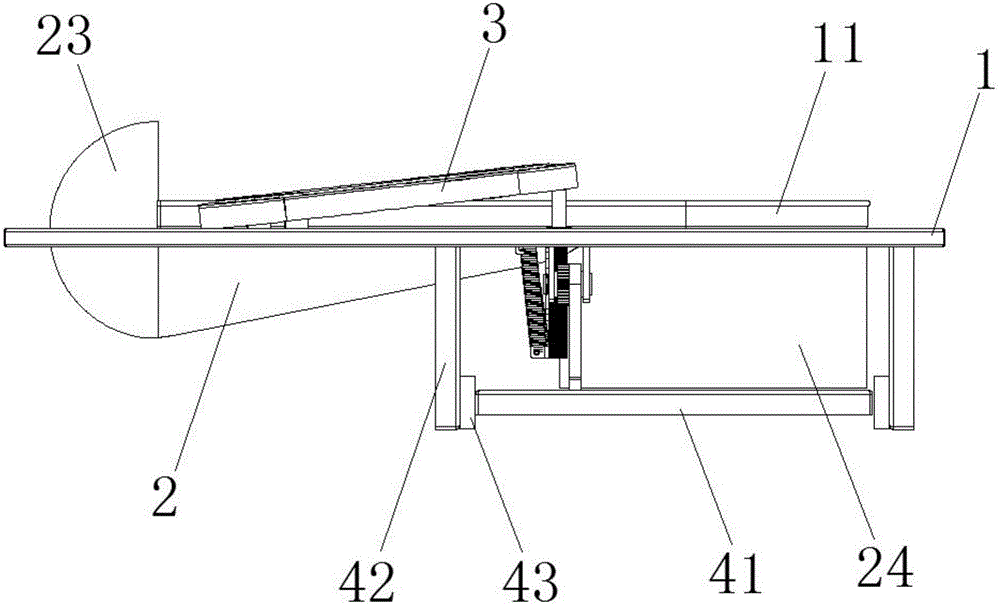

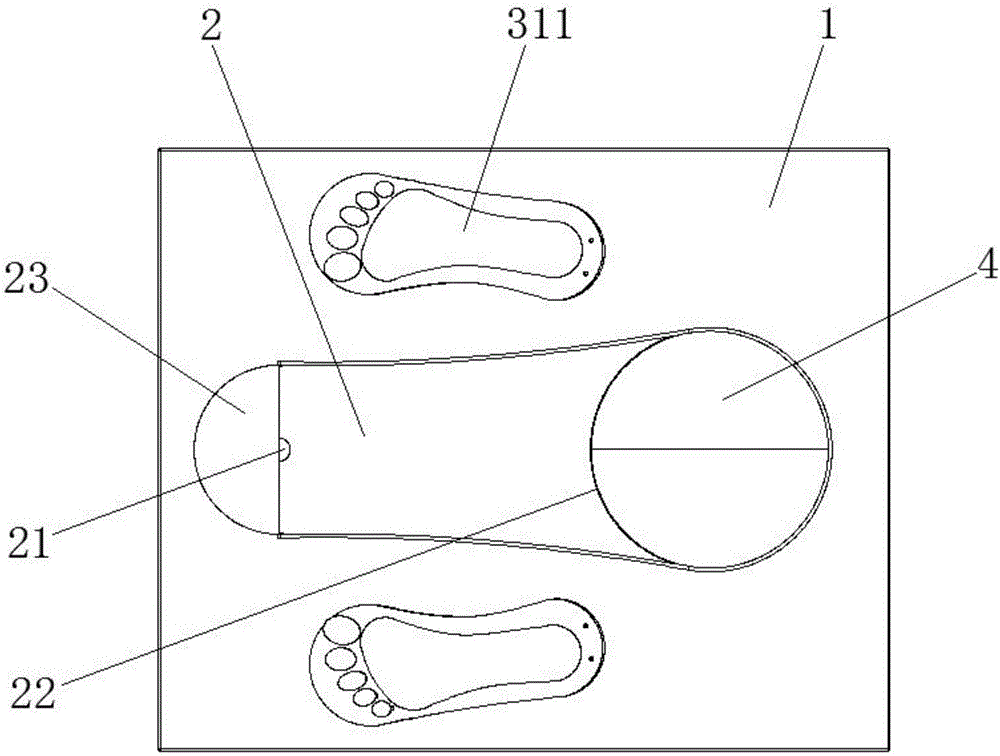

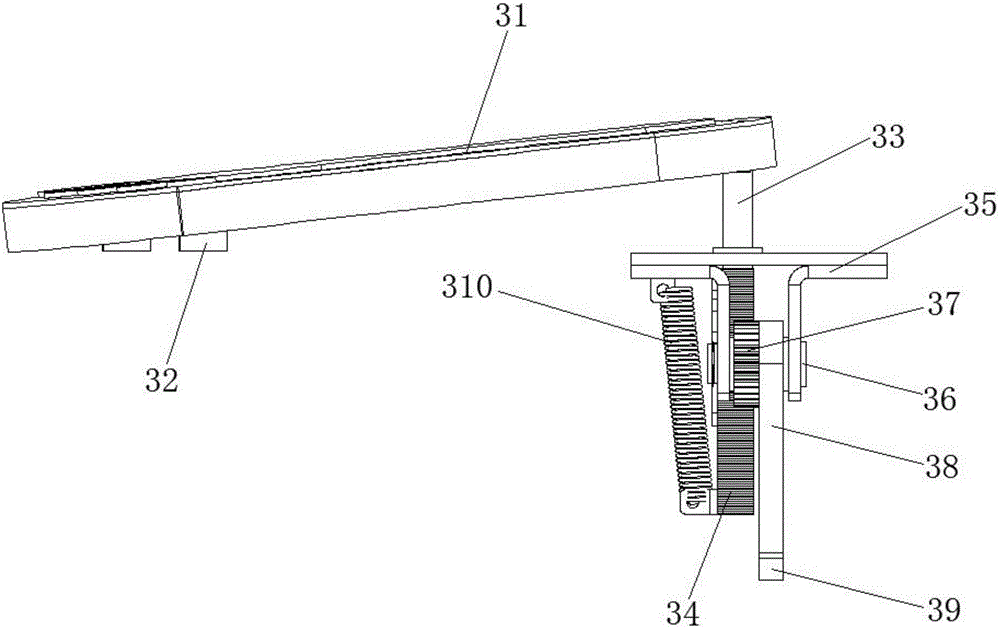

[0034] See Figure 1 to Figure 6 , The diverter valve type squatting toilet of this embodiment includes a panel 1, a bucket 2, a pedal driving mechanism 3 and a valve mechanism 4.

[0035] Panel 1 is a stainless steel panel, such as SUS304 stainless steel. The panel 1 is provided with upwardly raised patterns. The toilet 2 is arranged in the center of the panel 1 , and the front of the toilet 2 is provided with a urine drainage hole 21 , and the urine drainage hole 21 is arranged at the lowest point of the toilet 2 . The rear part of the toilet 2 is provided with a stool outlet hole 22, and the stool guide cylinder 24 is connected below the stool outlet hole 22, and the upper surface of the two valves 41 of the valve mechanism 4 is close to the outlet of the stool guide cylinder 24 of the toilet 2 end face. The upper front end of the closet 2 is provided with a urine stopper 23 . The panel 1 is provided with water retaining strips 11 arranged along both sides and the rear ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap