Separation method of natural product

A natural product and separation method technology, applied in the field of natural product separation, to achieve the effect of saving manpower and time, large peak capacity, and high-efficiency separation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

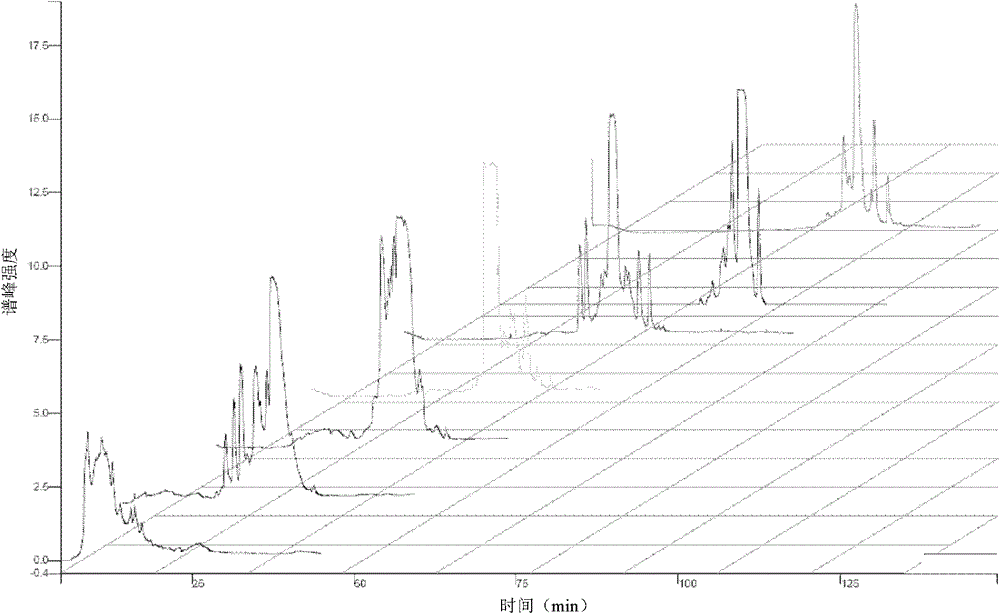

Examples

Embodiment 1

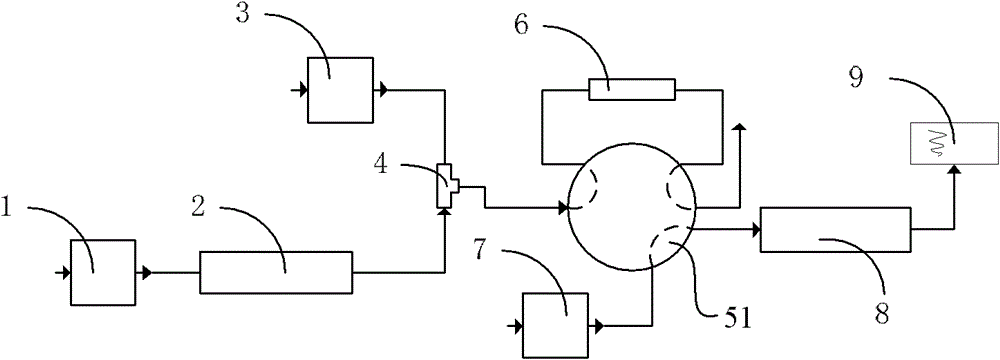

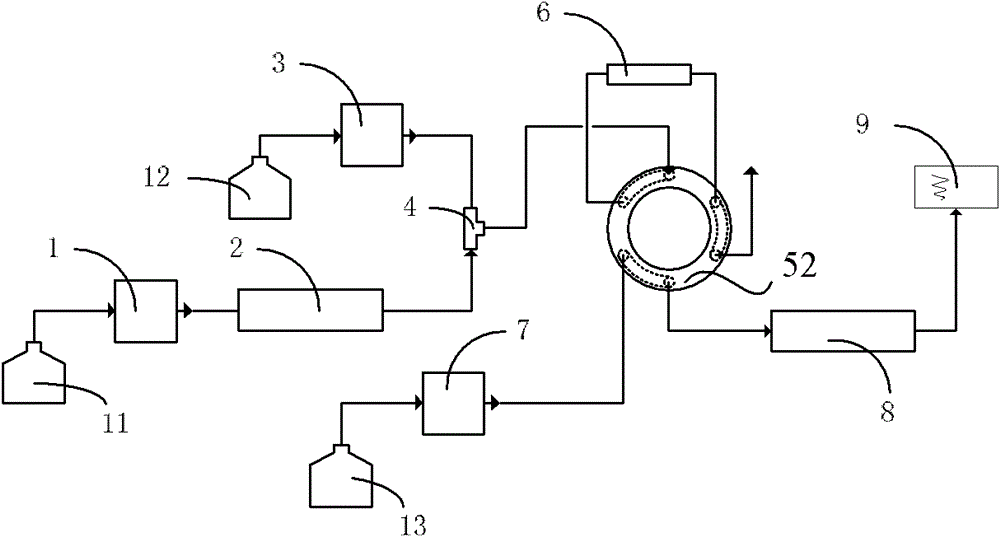

[0037] A method for the separation and preparation of natural products, the separation process adopts a comprehensive two-dimensional liquid chromatography method of high pressure liquid phase × preparative high performance liquid phase, the switching valve between the first dimension liquid chromatography and the second dimension liquid chromatography is Manual two-position six-way valve, the connection method is as follows figure 2 shown in figure 2Among them, each mark is: 1. First-dimension infusion pump (high pressure); 2. First-dimension liquid chromatography column (high pressure); 3. Diluent filling pump (high pressure); 4. Mixer; 52. Two-position Six-way valve; 6. Enrichment column; 7. Second dimension infusion pump (high pressure); 8. First dimension liquid chromatography column (preparation of high performance liquid chromatography column); 9. Detector; 11. First dimension wash Desolation; 12. Diluent; 13. Second dimension eluent.

[0038] Sample solution: 500mg...

Embodiment 2

[0064] A method for the separation and preparation of natural products. The separation process adopts a comprehensive two-dimensional liquid chromatography method of medium and low pressure liquid phase × preparative high performance liquid phase. The switching valve between the one-dimensional liquid chromatography and the second-dimensional liquid chromatography is Electronically controlled two-position ten-way valve, the connection method is as follows Figure 4 shown in Figure 4 Among them, each mark is: 1. First dimension infusion pump (medium and low pressure); 2. First dimension liquid chromatography column (medium and low pressure); 3. Diluent filling pump (medium and low pressure); 4. Mixer; 53 , two-position ten-way valve; 61, the first enrichment column; 62, the second enrichment column; 7, the second dimension infusion pump (high pressure); 8, the first dimension liquid chromatography column (preparation of high performance liquid chromatography column ); 9, dete...

Embodiment 3

[0092] A method for the separation and preparation of natural products. The separation process adopts a comprehensive two-dimensional liquid chromatography method of medium and low pressure liquid phase × preparative high performance liquid phase. The switching valve between the one-dimensional liquid chromatography and the second-dimensional liquid chromatography is A pair of synchronously switched six-position valves, the connection method is as follows Figure 6 shown in Figure 6 Among them, each mark is: 1. First dimension infusion pump (medium and low pressure); 2. First dimension liquid chromatography column (medium and low pressure); 3. Diluent filling pump (medium and low pressure); 4. Mixer; 54 , multi-position valve; 6, enrichment column; 7, second dimension infusion pump (high pressure); 8, first dimension liquid chromatography column (preparation of high performance liquid chromatography column); 9, detector; 11, first dimension Eluent; 12. Diluent; 13. Second di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com