A construction method for a double-layer storage tank with a flat ceiling on the inner tank

A double-layer storage tank and construction method technology, which is applied in the direction of building types, buildings, large-capacity bulk material storage, etc., can solve the problems of difficulty in transporting inner tank materials back into the tank, greater impact on project progress, and difficult construction, etc. Achieve the effect of reducing the amount of secondary installation and dismantling, improving the safety factor and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with the accompanying drawings, the present invention will be further described by describing the embodiments:

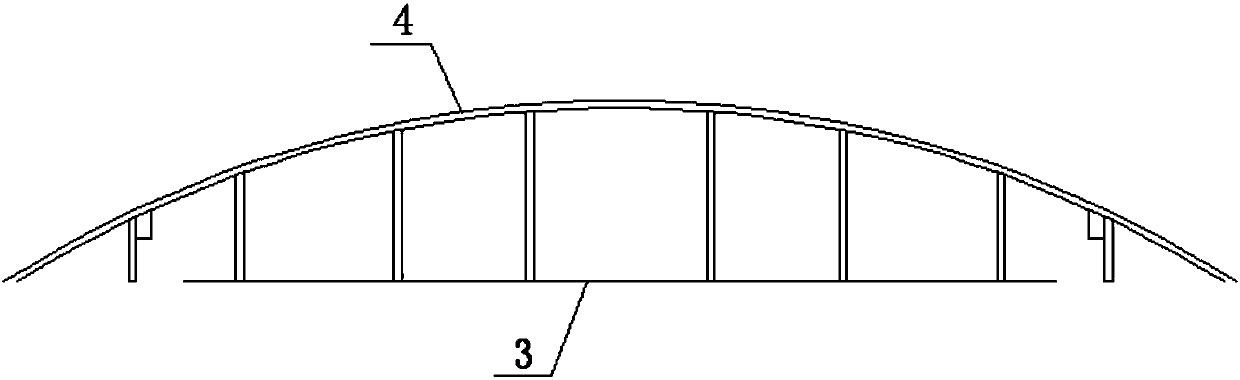

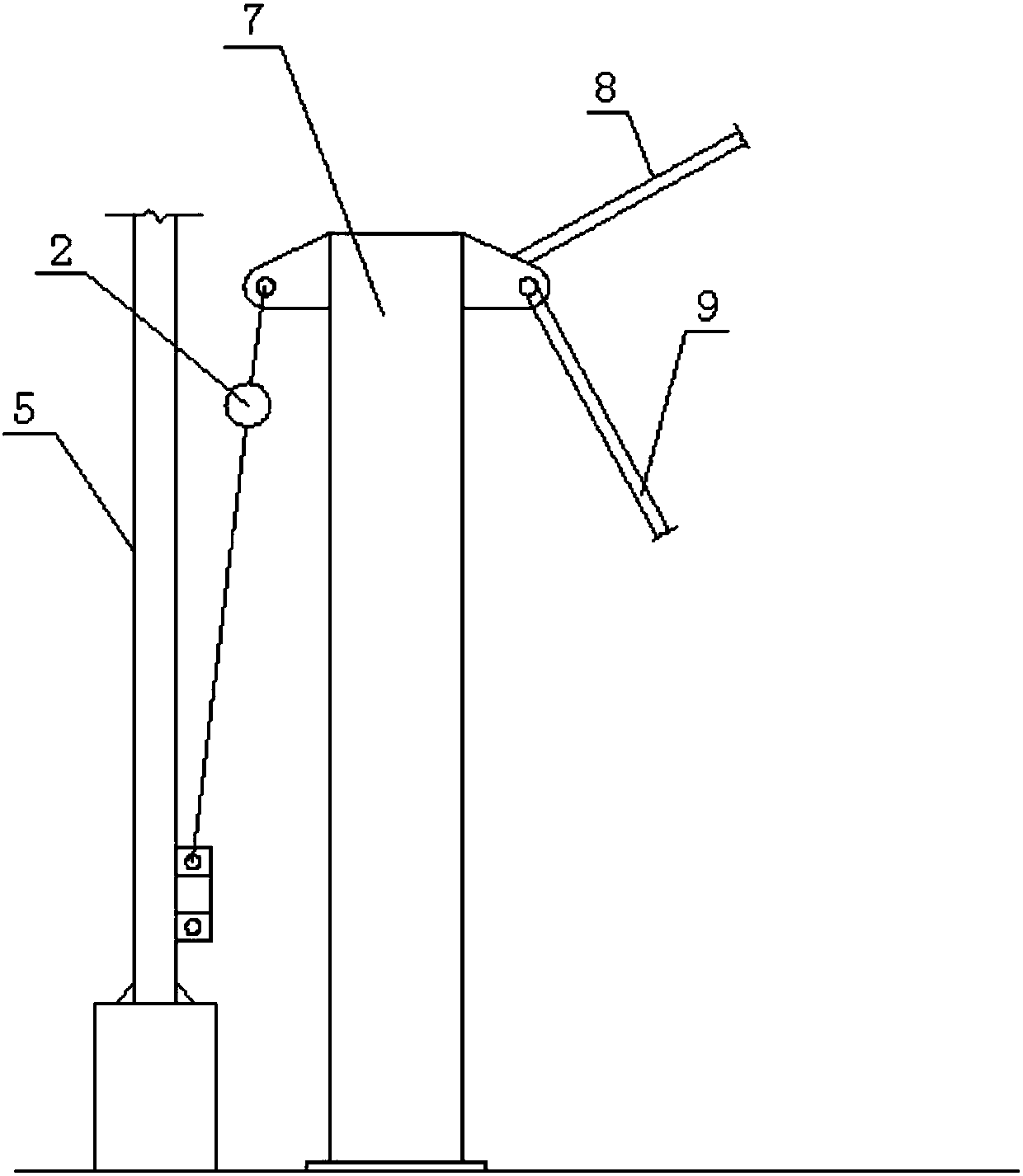

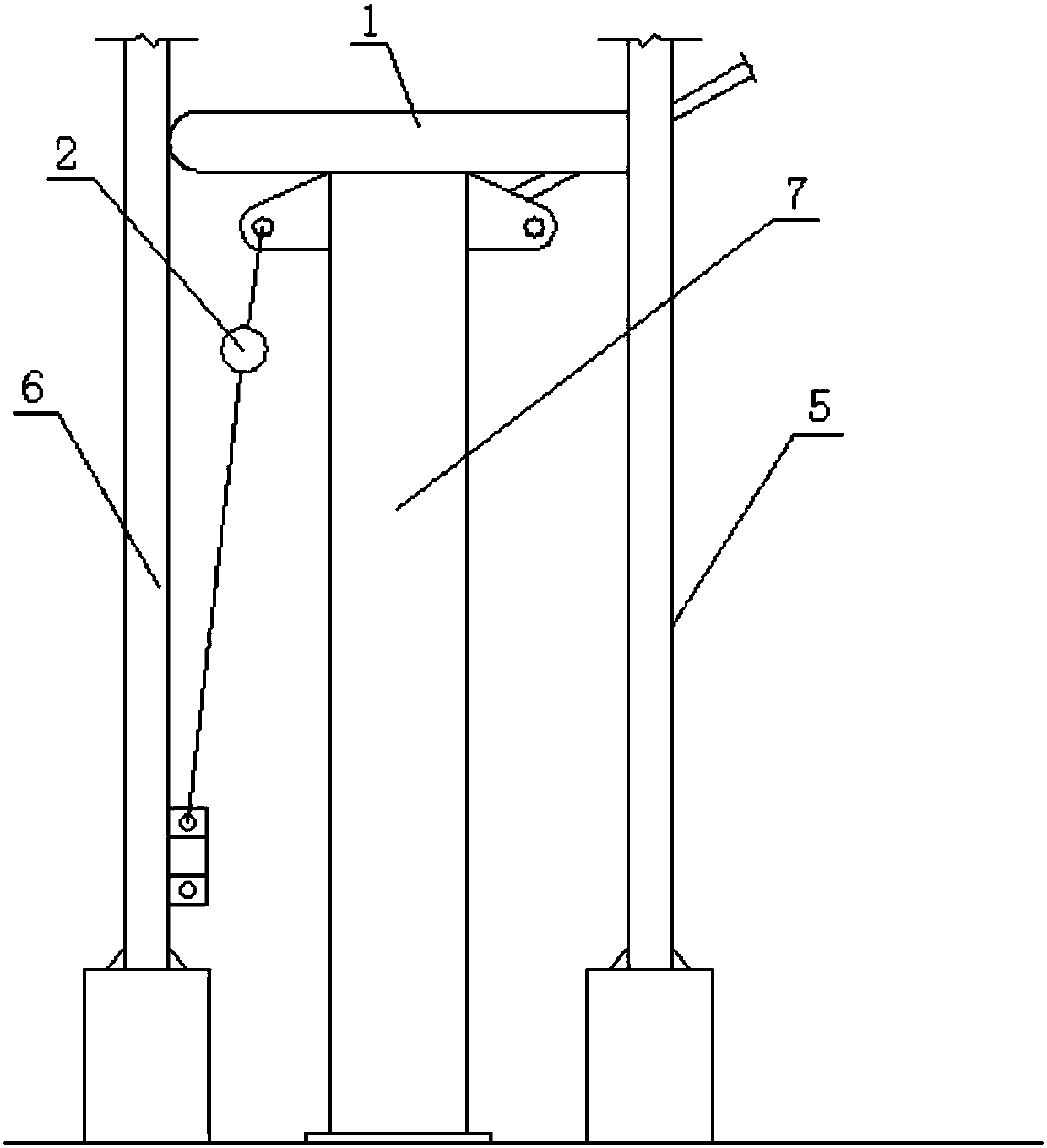

[0032] like figure 1 , 2 , 3, a construction method of a double-layer storage tank with a flat ceiling in the inner tank top of the present invention, including the construction of the inner and outer tank bottom plates, the construction of the inner tank flat ceiling 3, the outer tank dome top plate 4 and the inner tank wall plate 5. The construction of the outer tank wall panel 6 includes the following steps:

[0033] 1), cutting, prefabricating the inner and outer tank bottom plate, inner tank wall plate 5, outer tank wall plate 6, inner tank flat ceiling 3, outer tank dome roof plate 4 and parts.

[0034] 2) Assemble the bottom plate of the outer tank.

[0035] 3) After the outer tank bottom plate is assembled, prefabricate the inner tank flat ceiling 3 on the outer tank bottom plate, and then install the outer tank wall plate 6 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com