A maintenance ladder docked with a fixed ladder of a transmission tower

A technology for fixing transmission towers and poles, which is applied to ladders, buildings, building structures, etc., can solve the problems of shaking, unsafe, and inability of hooks to be clamped in maintenance ladders, so as to facilitate maintenance and construction, ensure maintenance safety, and improve labor efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

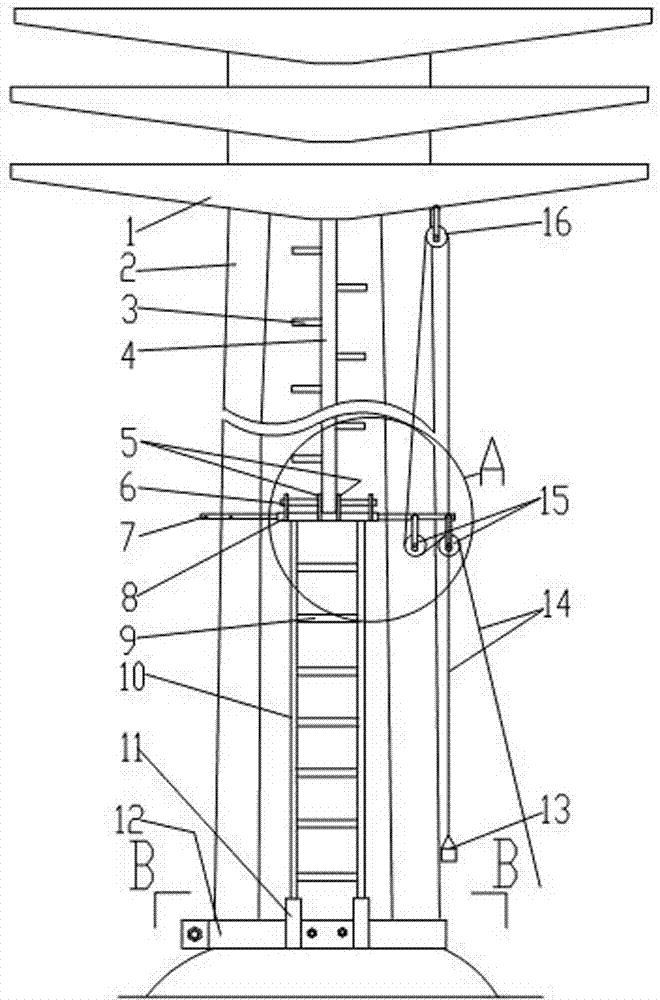

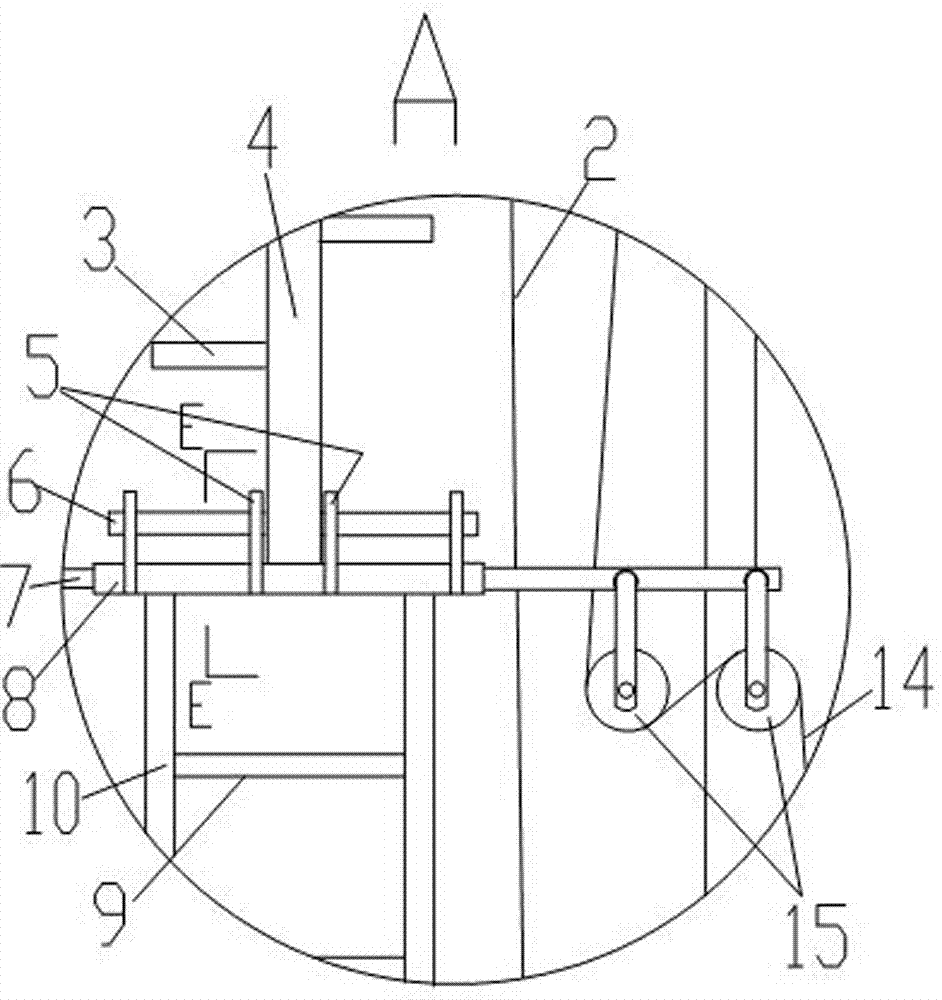

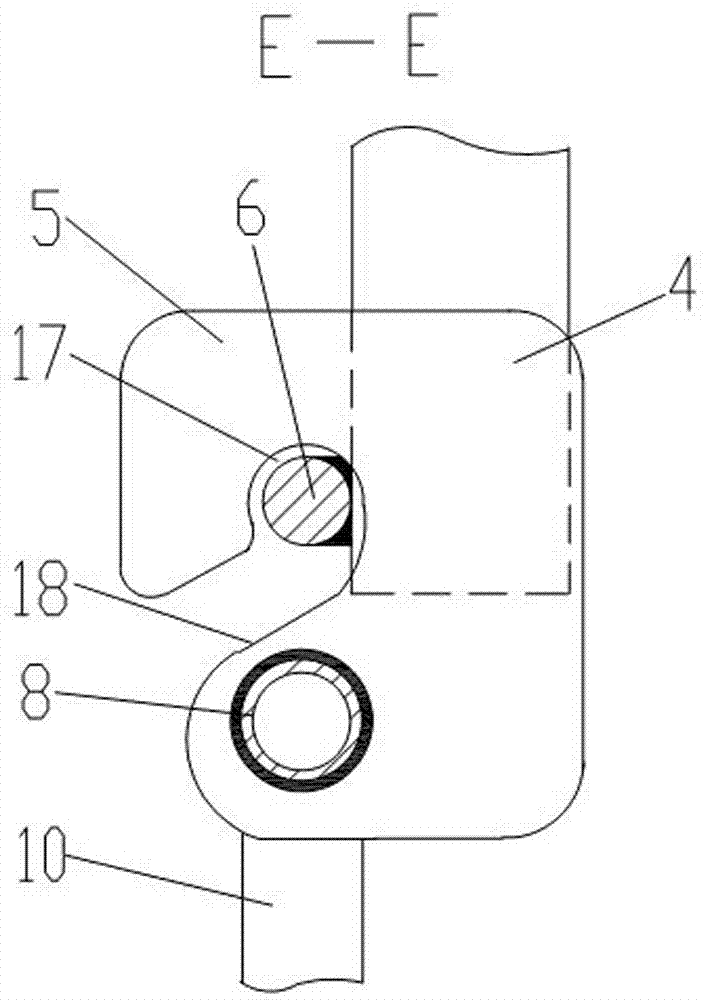

[0014] Embodiment 1: An inspection ladder docked with a fixed ladder of a transmission tower rod, including a landing ladder 10 and a plate hook 5; a round tube 8 is provided at the top of the landing ladder 10, and at least two A plate hook 5 is also hung on the cross bar 6 of the fixed ladder of the transmission tower rod, and two plate hooks 5 positioned at the middle part of the round pipe 8 are stuck in the middle of the column 4 of the fixed ladder of the transmission tower rod. The landing ladder 10 is a frame ladder with risers on both sides; the plate hook 5 is a flat plate, and the flat plate is provided with a hook hole 17 and a hook channel 18, and the diameter of the hook hole 17 is larger than the cross bar of the fixed ladder 6, the hook hole 17 is located above the hook channel 18 and communicates with the hook channel 18. Also comprise transverse tube 7, suspension pulley 16, block pulley 15, stay rope 14 and hanging basket 13; Described transverse tube 7 trav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com