Test device and test method for determining the ratchet effect of straight pipelines under high temperature and high pressure

A high-temperature, high-pressure, and test-device technology that is applied to measuring devices, using repeated force/pulsation force to test material strength, instruments, etc., can solve the problem of finite element analysis software deviation, high-temperature ratchet effect dilemma, and difficulty in accurately obtaining high-temperature ratchet effect of materials Data and other issues to achieve the effect of preventing damage and stabilizing the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with embodiment.

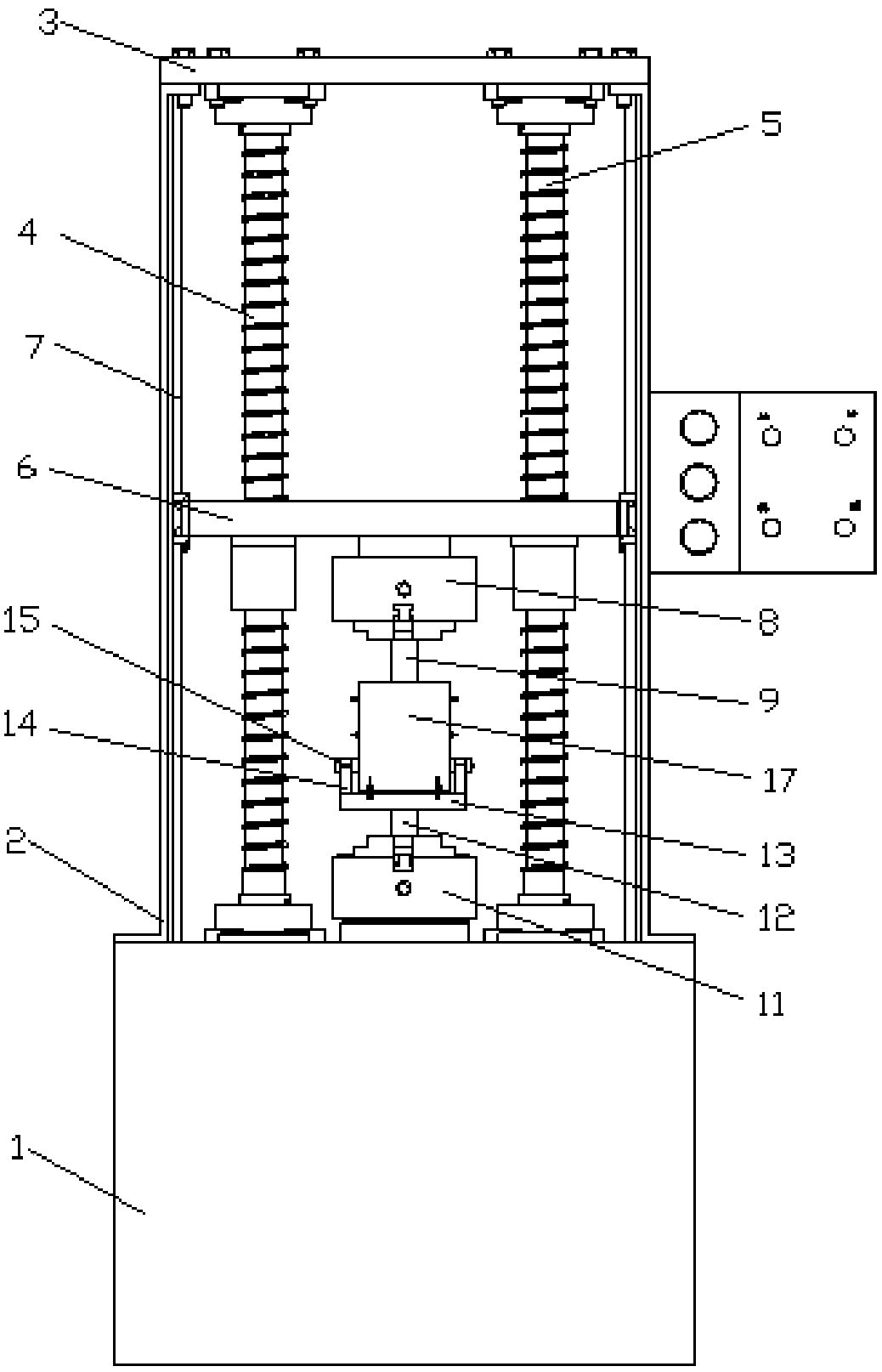

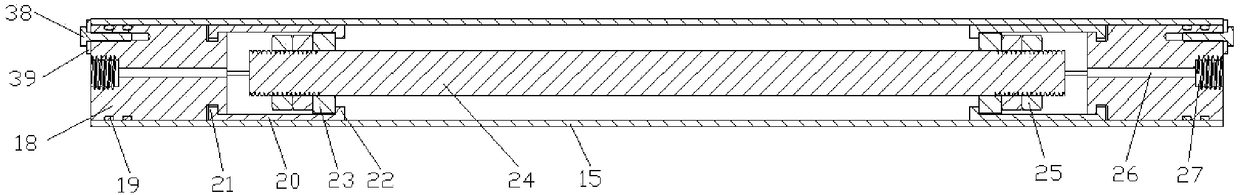

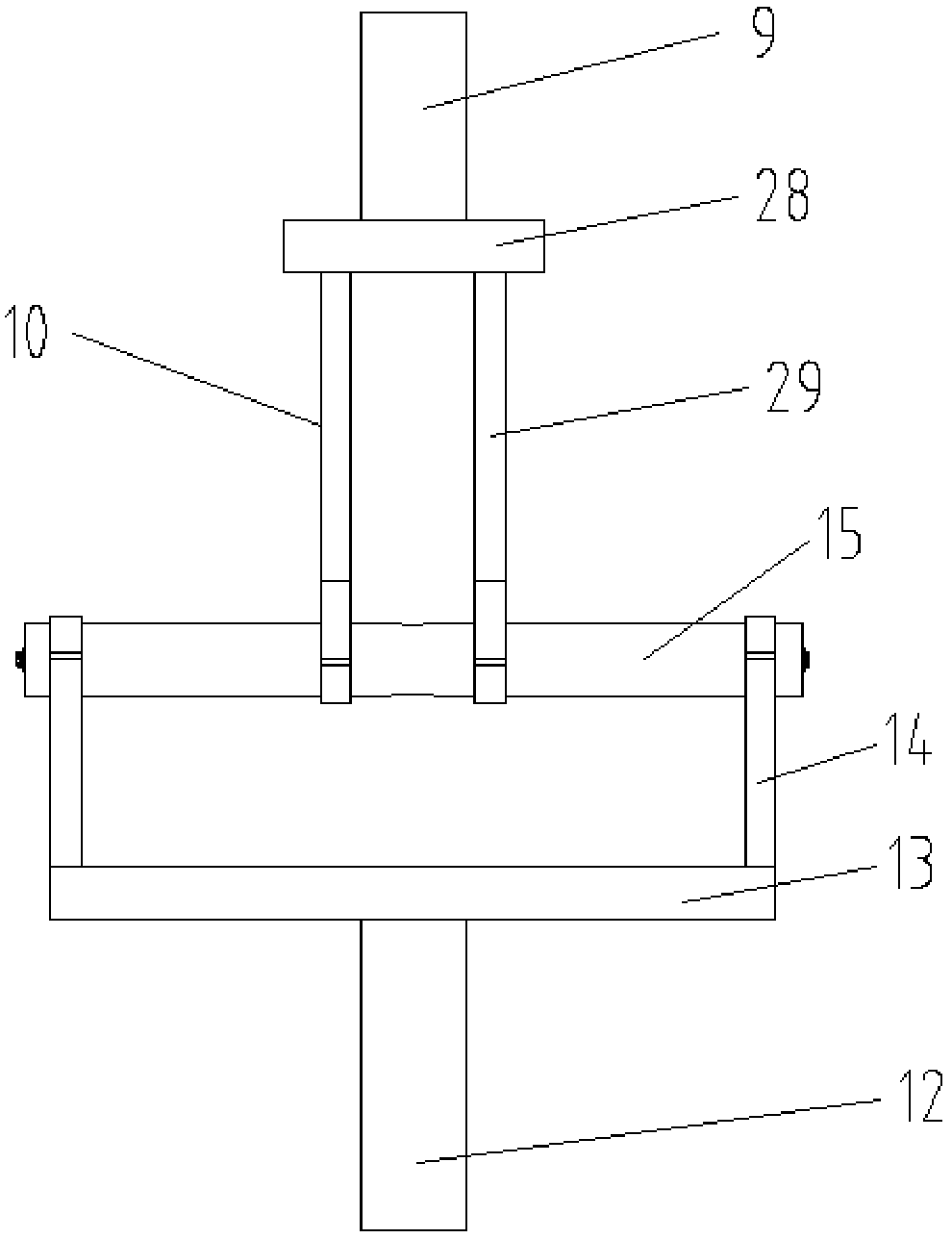

[0033] according to figure 1As shown, a test device for measuring the ratchet effect of straight pipes under high temperature and high pressure, including a base 1, a frame 2 is arranged on the upper part of the base 1, a cover plate 3 is arranged on the upper part of the frame 2, and one end of the first screw 4 and the second screw 5 It is connected with the cover plate 3, and the other end is connected with the base 1. The first screw 4 and the second screw 5 are provided with a first connecting plate 6, and the inner wall of the frame 2 is provided with a slideway 7. The first connecting plate The two ends of 6 are embedded in the slideway 7, so that the first connecting plate 6 slides along the slideway 7, and the upper chuck 8 is fixed on the first connecting plate 6, and the upper chuck 8 is fixed on the first connecting plate. 6 is driven to move up and down, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com