Mainboard combined measurement machine and test method thereof

A motherboard and joint testing technology, applied in the direction of electronic circuit testing, etc., can solve the problems of long waiting time for motherboard testing, labor-intensive operation of employees, cumbersome processing of fixtures, etc., to reduce test waiting time, reduce manual labor, fixtures, etc. The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below according to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

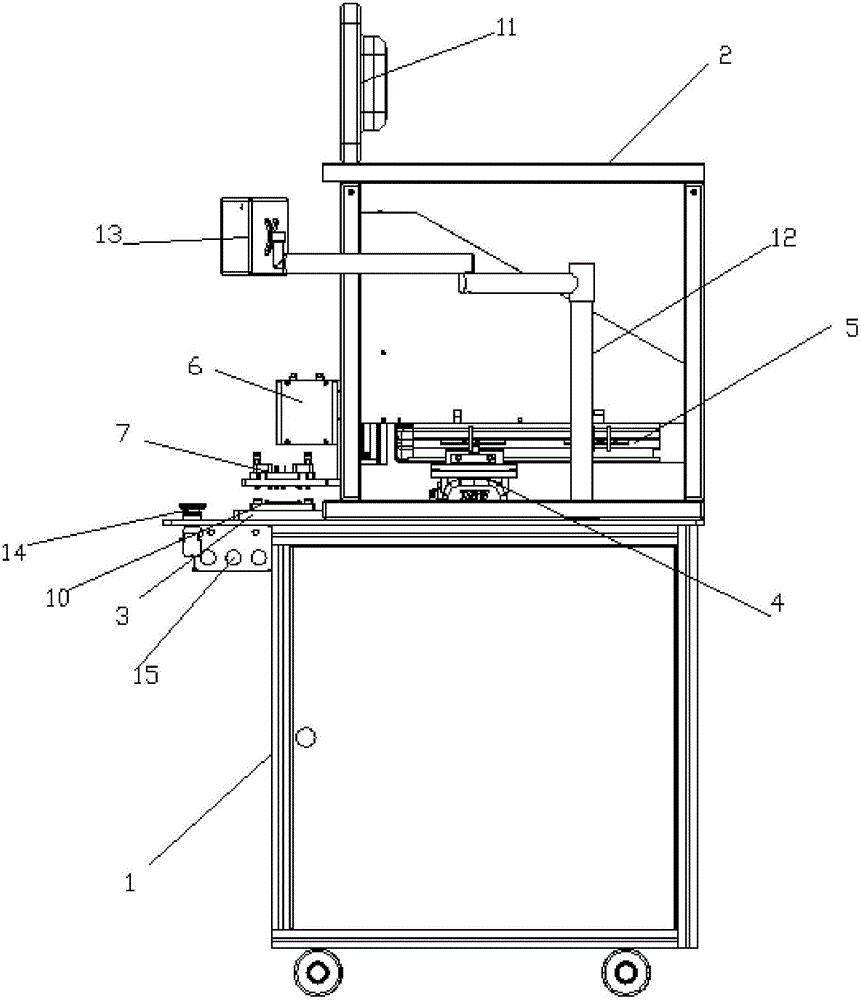

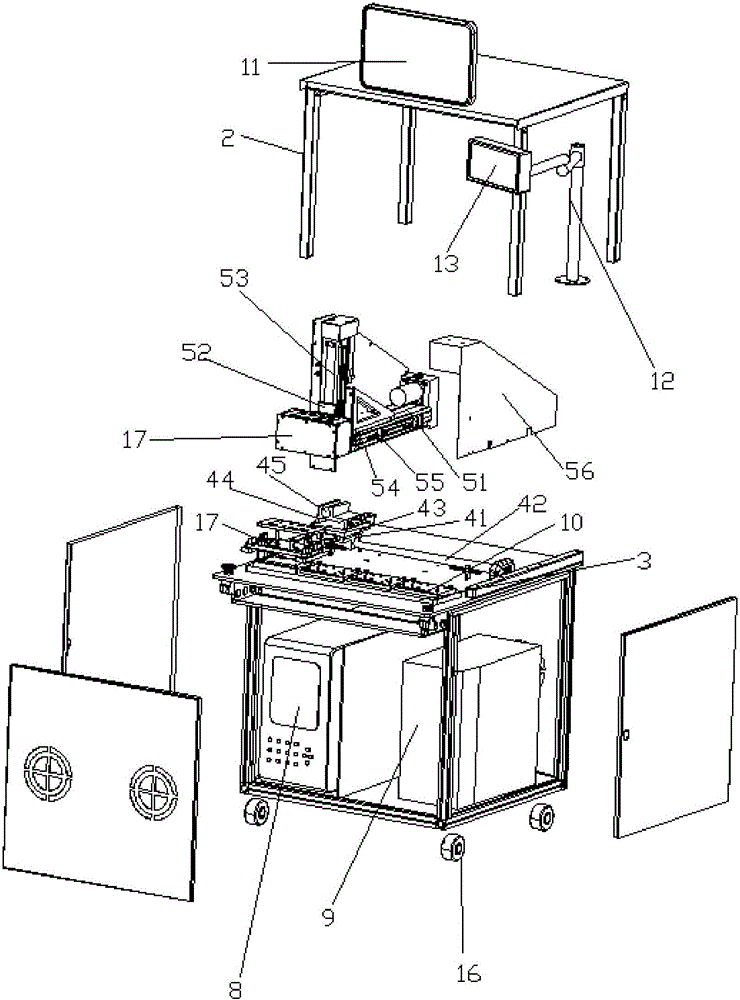

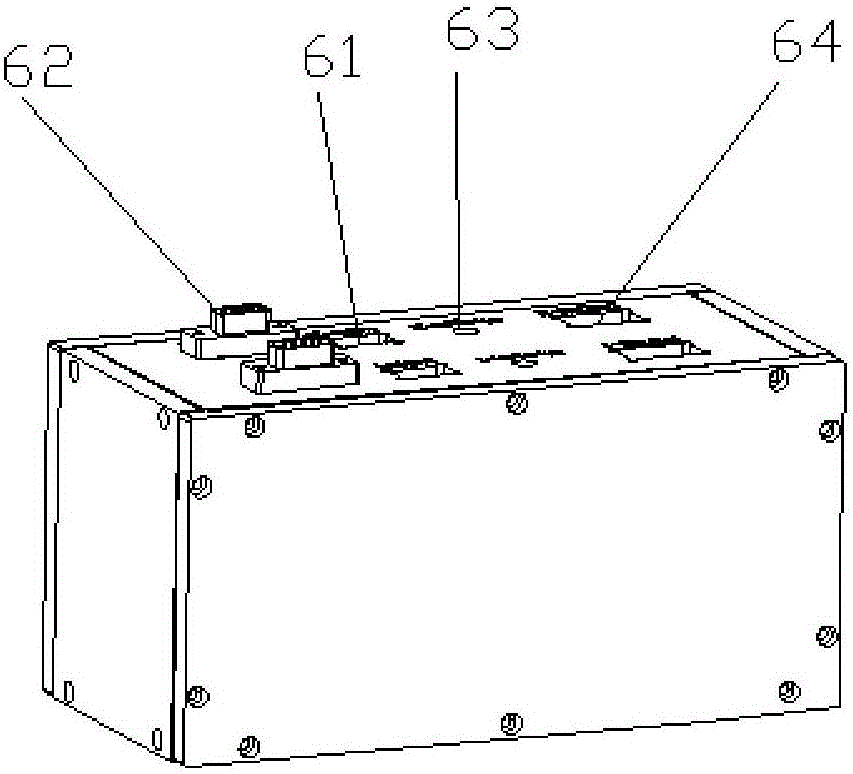

[0027] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a main board joint testing machine includes a lower frame 1 and an upper frame 2, the upper frame 2 is installed on the lower frame 1, and the upper plane of the lower frame 1 is provided with a fixture installation base plate 3 and left and right screw screws Control device 4, an upper and lower lead screw control device 5 is installed on the left and right lead screw control device 4, a communication adapter 6 and a test fixture 7 are installed on the upper and lower lead screw control device 5, and a PLC master is also arranged in the lower frame 1. The control box 8 and the computer mainframe 9 are provided with a plurality of fixture positioning plates 10 at intervals on the fixture installation base plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com