YAG laser welding power supply control system having online fault diagnosis and debugging functions

A debugging function and laser welding technology, which is applied in the direction of program control system, general control system, control/regulation system, etc., can solve the problems of incomplete functions, delay of user production time, increase of product maintenance cost, etc., and achieve simple and convenient maintenance. The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

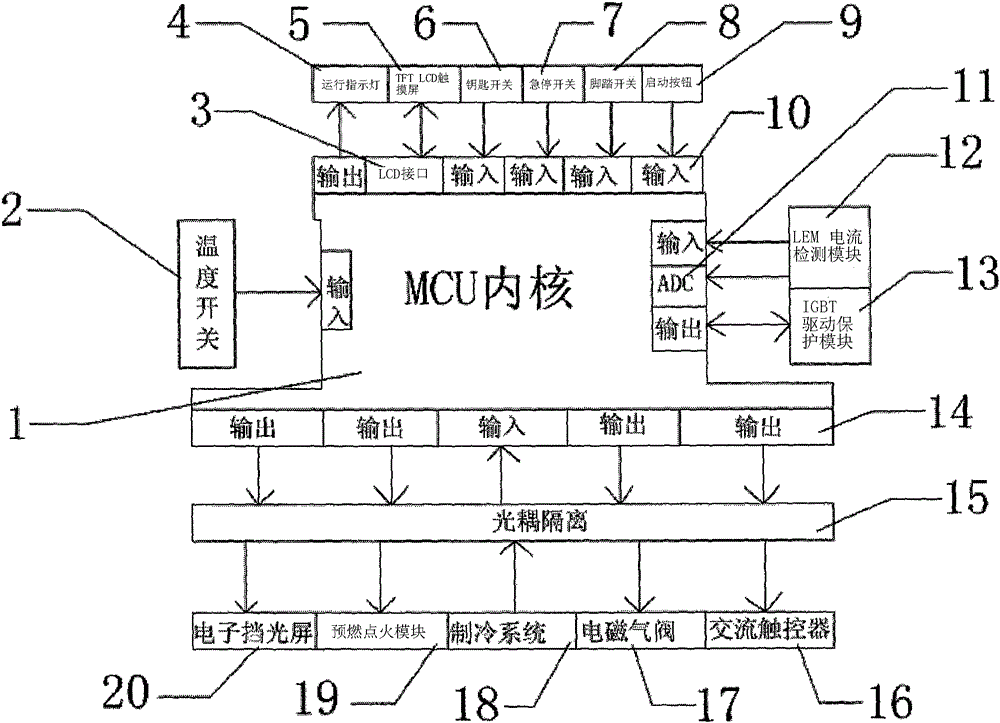

[0012] The present invention provides such figure 1 A YAG laser welding power supply control system with online fault diagnosis and debugging functions shown in the figure, including running indicator light 4, TFT LCD touch screen 5, key switch 6, emergency stop switch 7, foot switch 8, start button 9, temperature Switch 2, LEM current detection module 12, IGBT drive protection module 13, optocoupler isolation 15, electronic light shield 20, pre-ignition ignit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap