A kind of preparation method of graphite-tin composite material for negative electrode of lithium ion battery

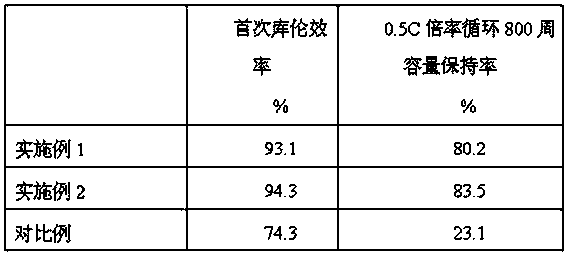

A technology for lithium ion batteries and composite materials, which is applied in the field of preparation of graphite-tin composite materials, can solve the problems of difficult storage, high product reactivity, and complicated preparation process of tin-based material fine powder, and achieves the effect of high coulombic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of graphite tin composite material for lithium ion battery negative electrode, the steps are as follows:

[0026] A1. Add natural flake graphite with a purity of 99.95% and a particle size of 200 mesh and tin oxide with a particle size of 3μm into the fusion machine at a ratio of 100:5. 2 Under protective atmosphere, heat to 250℃ and keep constant temperature for 2h. During heating and constant temperature, the fusion machine keeps high-speed stirring at 3000rpm;

[0027] A2. The fusion material obtained in step A1 is directly vacuum conveyed from the fusion machine to the VC mixer, and an appropriate amount of asphalt with a softening point of 180℃ is added for mixing and coating. The total amount of asphalt is the quality of the natural flake graphite in step A1 The mixing and coating speed is 200rpm, and the mixing and coating time is 30min;

[0028] A3. Put the coating material obtained in step A2 into the crucible by the manipulator, and then place it...

Embodiment 2

[0031] A preparation method of graphite tin composite material for lithium ion battery negative electrode, the steps are as follows:

[0032] A1. First spray natural flake graphite with a purity of 99.95% and a particle size of 200 mesh with an oxidant solution to form uneven oxidation pits on the surface. The oxidant solution can be peroxide, permanganic acid, or chlorate. , Hydrochloric acid, sulfuric acid, etc. Then the oxidized natural flake graphite is laid flat on the bottom surface of the fusion machine. The fusion machine adopts interval heating, first heating to 200~300℃, and then cooling to 0~10℃, heating and cooling alternately, interval time period When the natural flake graphite is curled and deformed, use a spray granulator to spray tin oxide particles with a temperature of 1600°C-1630°C. The size of the tin oxide particles is 7μm, and the quality of the natural flake graphite and tin oxide Spray in the ratio of 100:20, in N 2 Heat to 400°C under a protective atmos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com