Variable-speed pumped storage generator motor rotor winding end socket insulating box fixing structure

A generator motor and rotor winding technology, applied to the shape/style/structure of winding insulation, electric components, windings, etc., can solve problems such as increased cavitation, low efficiency of water turbines, wear and vibration, etc., to improve reliability and facilitate Installation, the effect of preventing direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

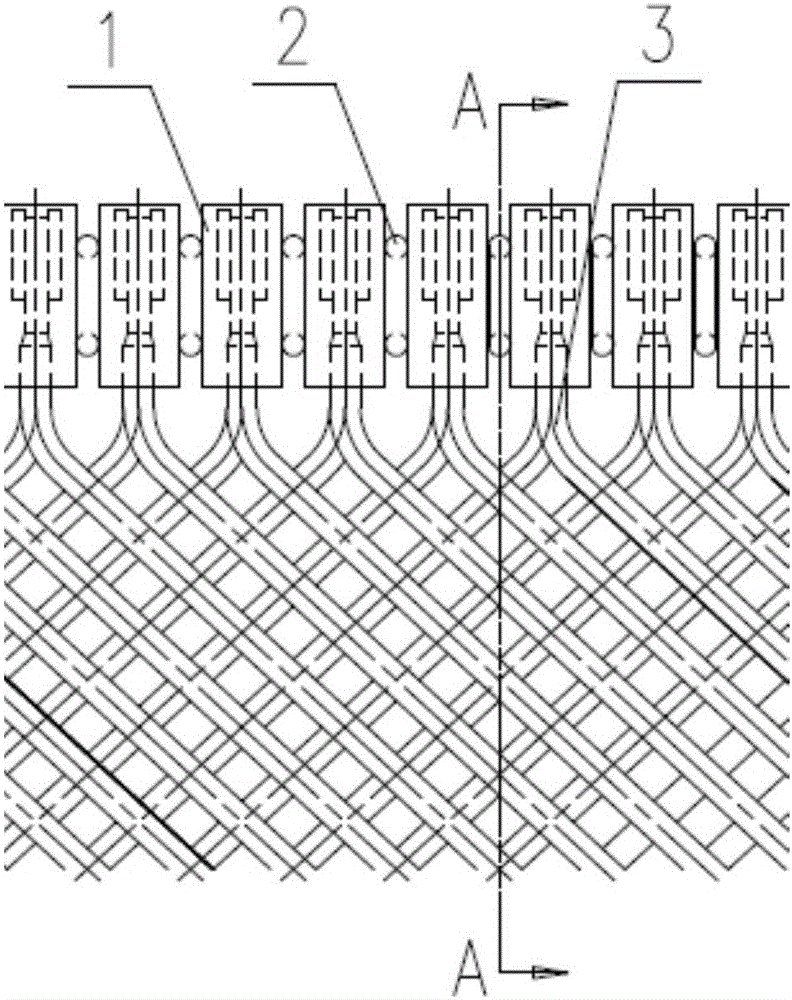

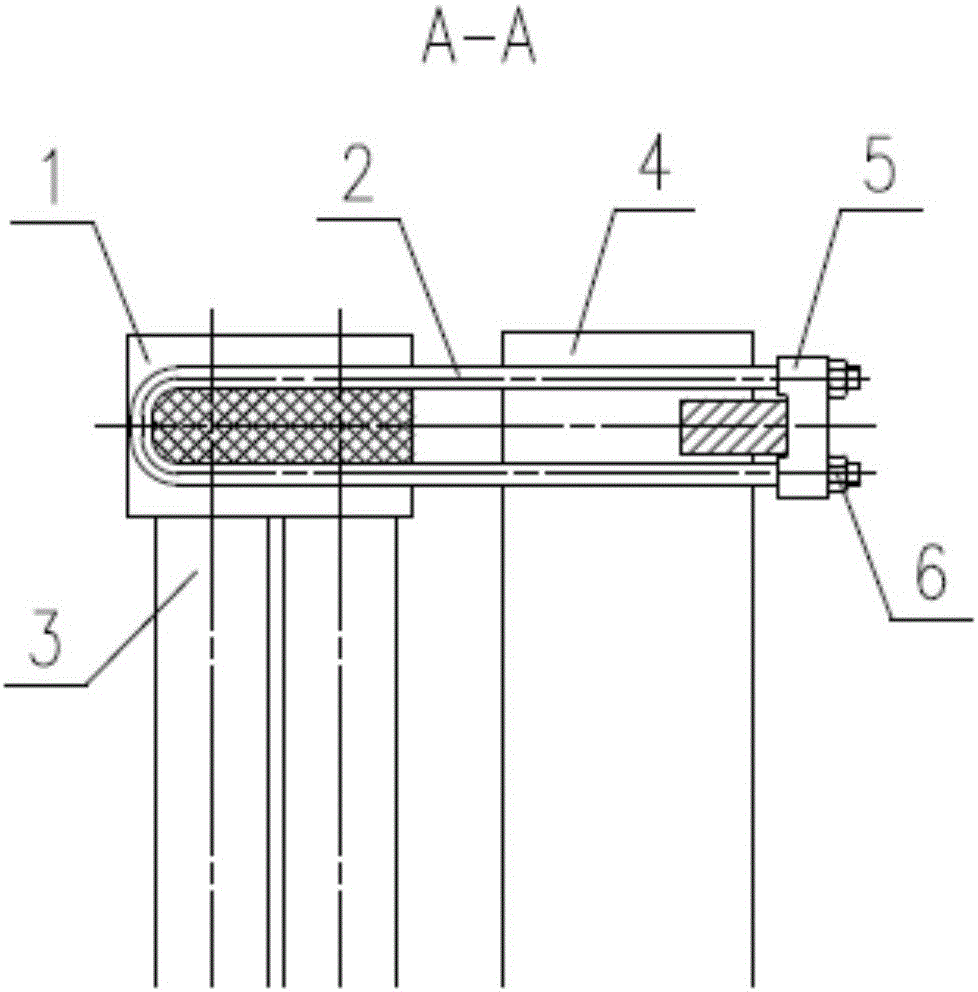

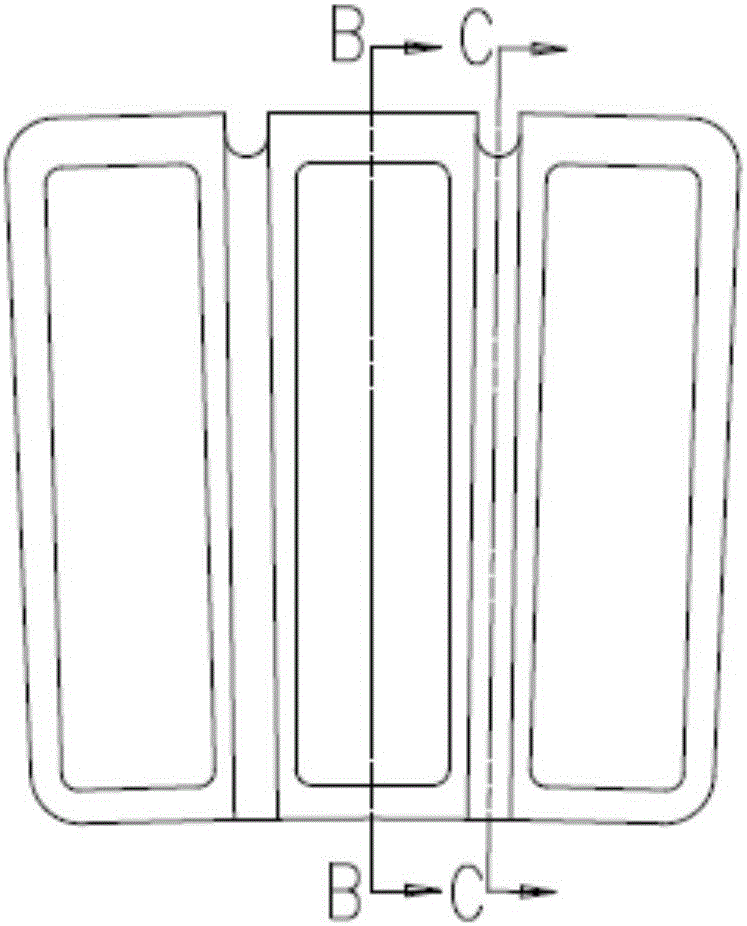

[0019] Such as figure 1 As shown in the figure, the rotor winding of the variable speed pumped storage generator motor adopts strip-type wire rods made of red copper. During operation, a large current passes through the wire rods. Pay attention to the insulation between the winding ends. The large-scale variable-speed pumped-storage generator motor rotor winding terminal insulation box fixing structure proposed by the present invention is composed of a connected insulation box 1, a fixed screw rod 2, a fixed frame 4, an insulating block 5, and a fixed nut 6; the connected insulation box 1 It is made of high-strength insulating material through molding and machining. It is composed of three cavities arranged in a fan shape. Each cavity corresponds to a rotor winding end 3. There is a groove between two adjacent cavities for penetration. Through the fixed screw 2; the fixed screw 2 is made of non-magnetic material, U-shaped structure, and the outer side is covered with insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com