Broadleaf holly leaf dewatering equipment

A greening equipment and technology of Kudingcha, applied in the direction of tea treatment before extraction, can solve the problems of affecting the shape of tea leaves, easy drying and brittleness, gaps in the leaf edge, etc., to avoid damage, improve the greening effect, and maintain the shape of tea leaves. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

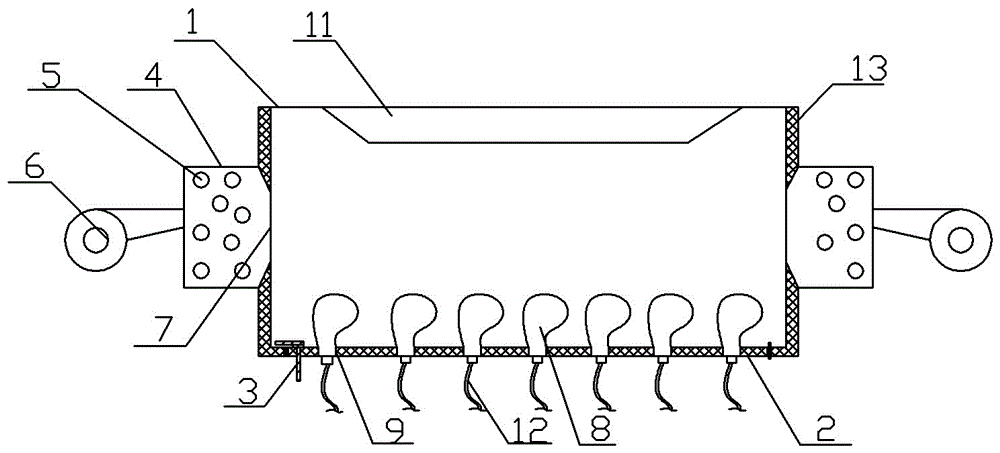

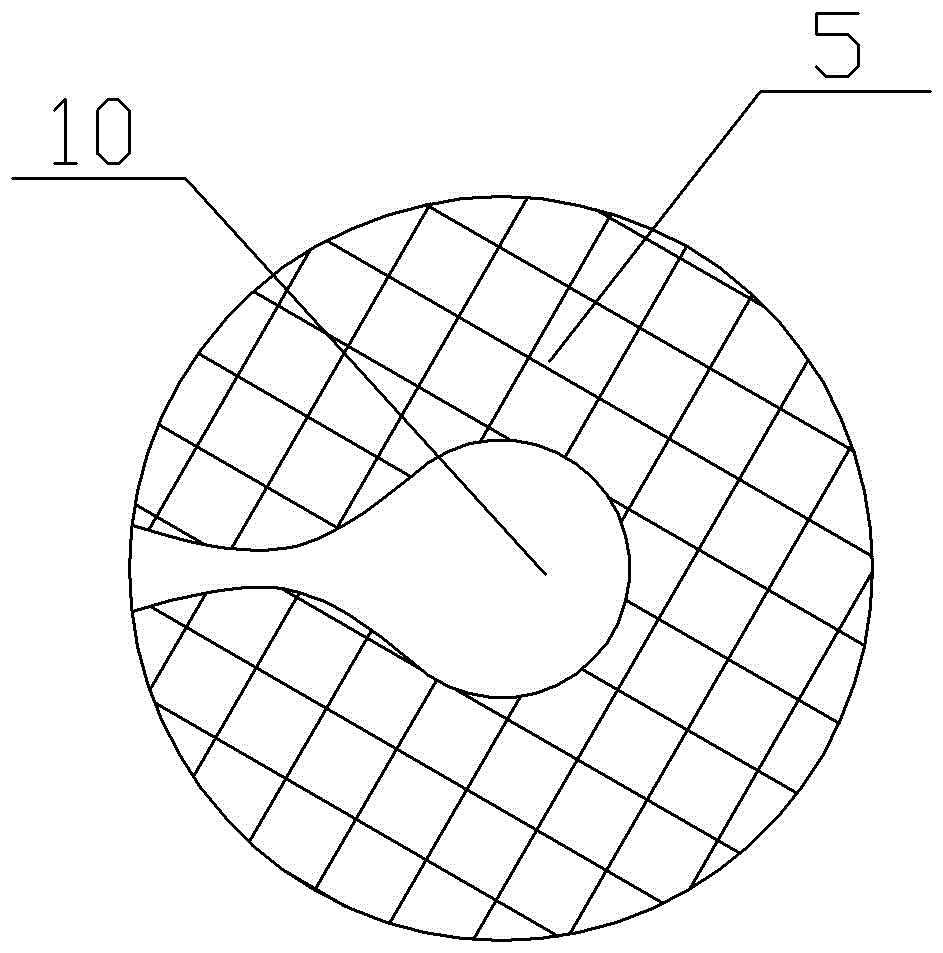

[0016] Embodiment A kind of Kudingcha degreening equipment is basically as attached figure 1 , figure 2 Shown: comprise the recumbent clearing tube 1, the upper end of this clearing tube 1 is provided with the feeding port 11 of tealeaves, and the lower end of the clearing tube 1 is equipped with discharge plate 2. One end of the discharging plate 2 is hinged with the fixing tube 1 through a pin shaft, and the other end is rotated through an L-shaped rod 3, and the short arm of the L-shaped rod 3 is located in the fixing tube 1 (that is, inside the discharging plate 2). , the long arm wall of the L-shaped rod 3 runs through the discharge plate 2 and is located outside the fixing tube 1. When the short arm wall is turned to the left, the discharge plate 2 can be hung on the fixing tube 1. When the short arm wall is turned to the left , the discharge plate 2 rotates counterclockwise, thereby opening the killing cylinder 1. Both the inner wall of the killing cylinder 1 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com