A dry ice blasting machine

A technology of dry ice cleaning and dry ice, applied in the direction of cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of poor mobility of equipment, high labor intensity of workers, and low degree of automation, and achieve convenient operation, high degree of automation, and safety high performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

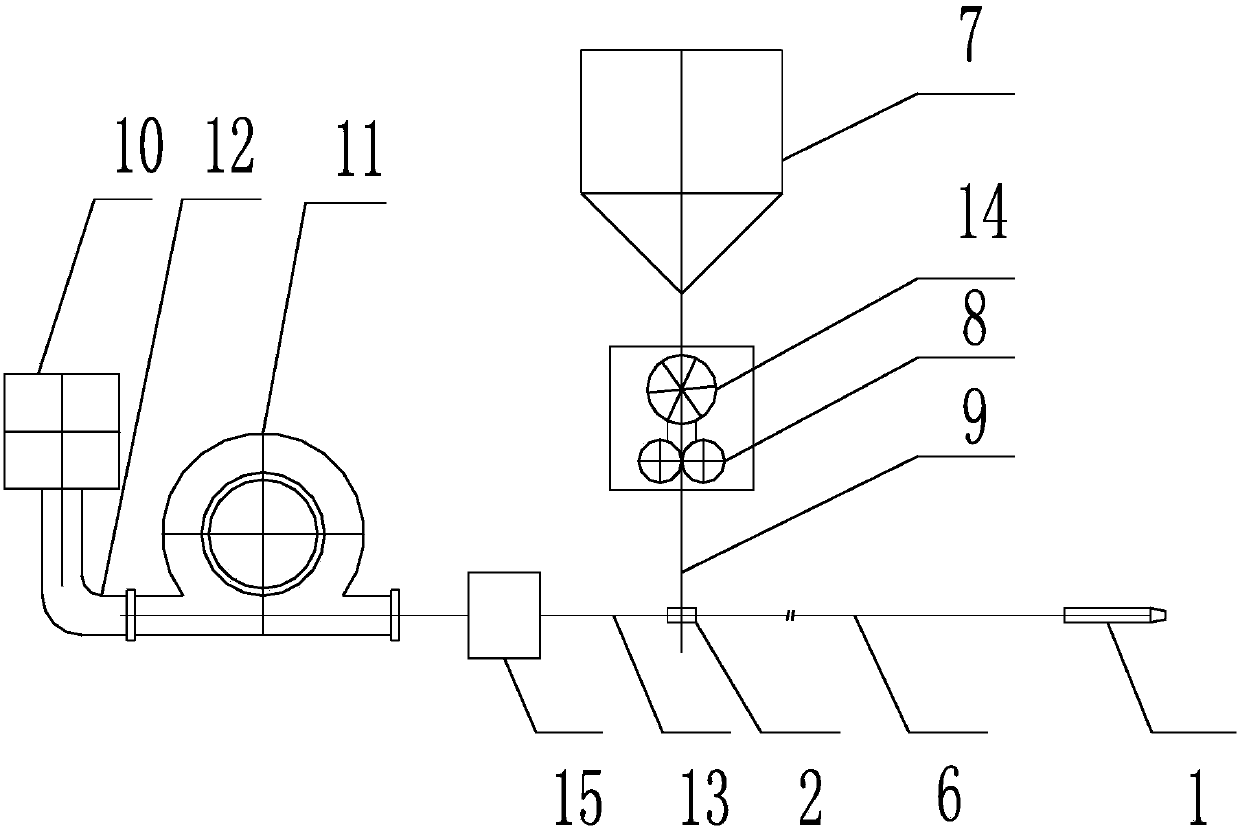

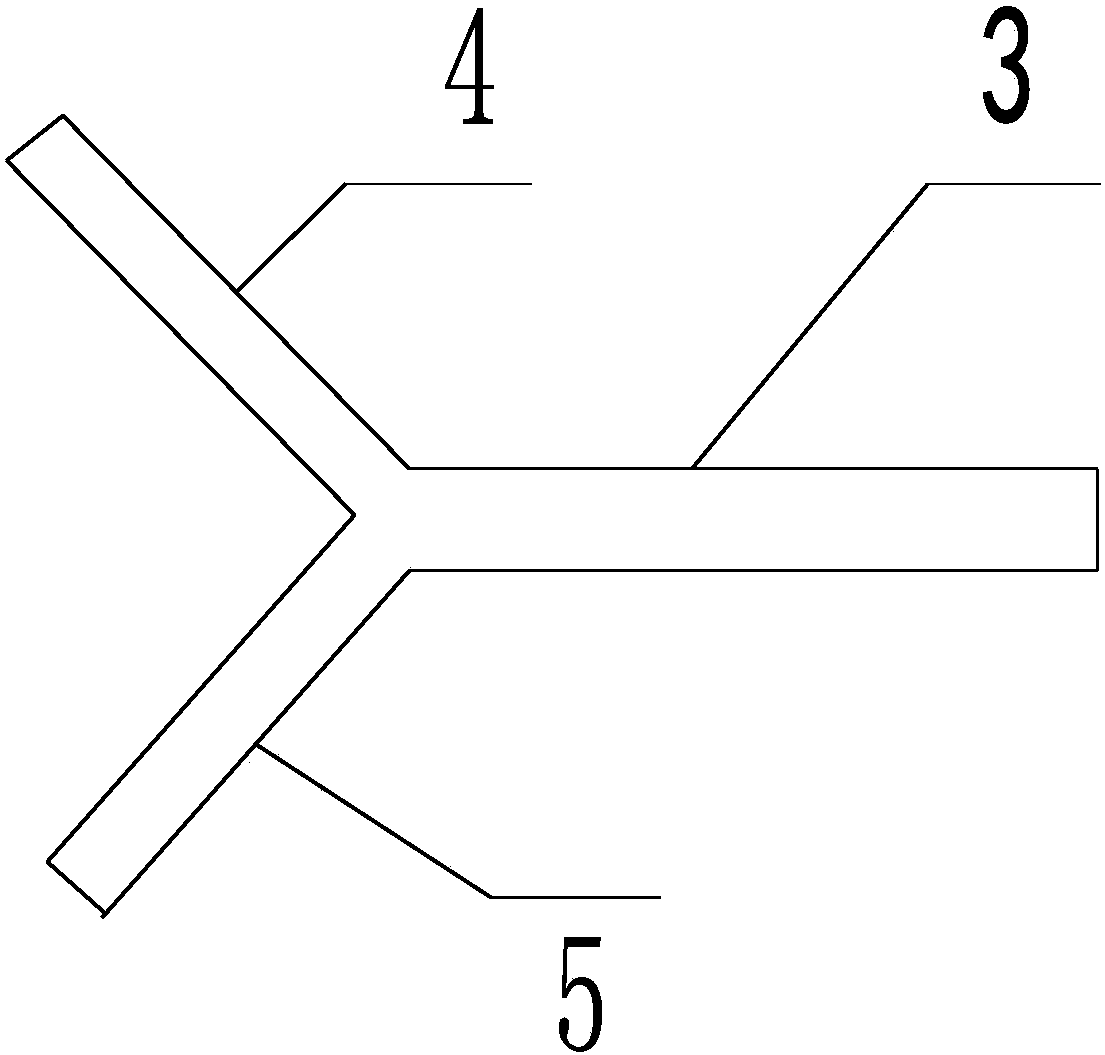

[0022] Attached below Figure 1-2 The specific structure of the dry ice blasting machine of the present invention is described in detail.

[0023] A dry ice blasting machine, the dry ice blasting machine includes a spray gun 1, a dry ice supply assembly, an air power source assembly and a power supply assembly; wherein, the spray gun is connected to the dry ice supply assembly and the air power source through a three-way pipe 2, and the three-way pipe Including the first port 3, the second port 4 and the third port 5 respectively, the spray gun is connected to the first port through the connecting branch pipe 6; the dry ice supply assembly includes a hopper 7, a dry ice pulverizer 8, a dry ice particle delivery pipe 9, and a dry ice pulverizer It is respectively connected with the discharge port of the hopper and the dry ice particle conveying pipe, and the dry ice particle conveying pipe is connected with the second port; the air power source includes an air filter 10, a mult...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap