Two-dimensional numerical control electric discharge machining rotating table

A technology of electric discharge machining and turntable, which is applied in the direction of electric processing equipment, metal processing equipment, manufacturing tools, etc., and can solve the problems that cannot meet the processing needs of complex workpieces and multi-curved workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

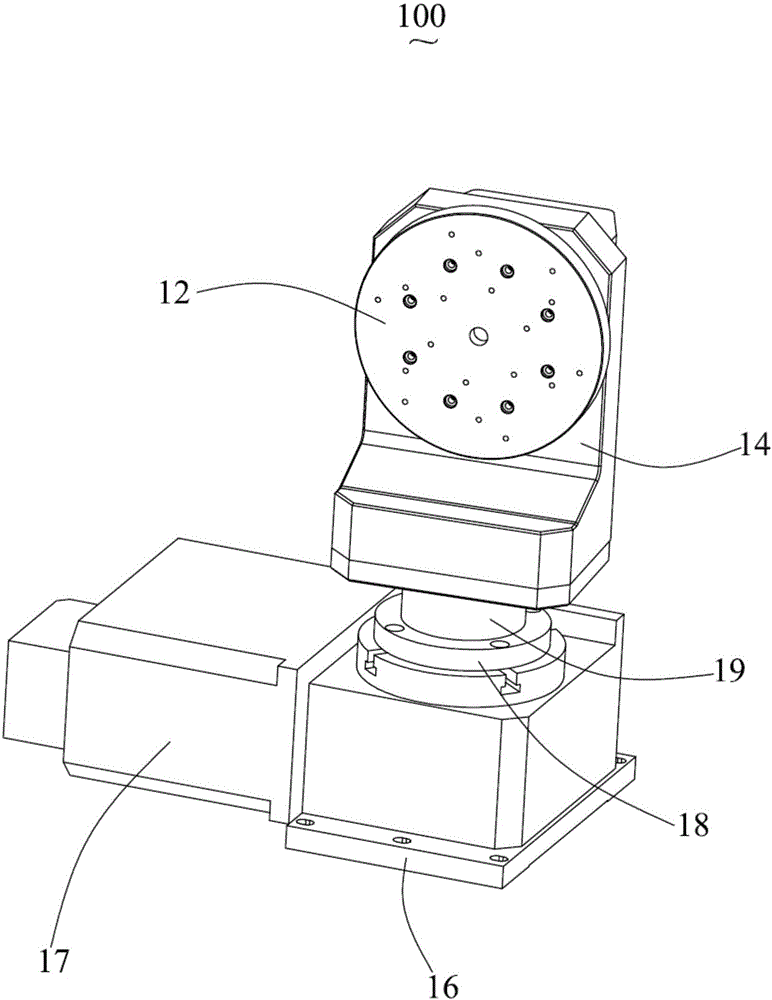

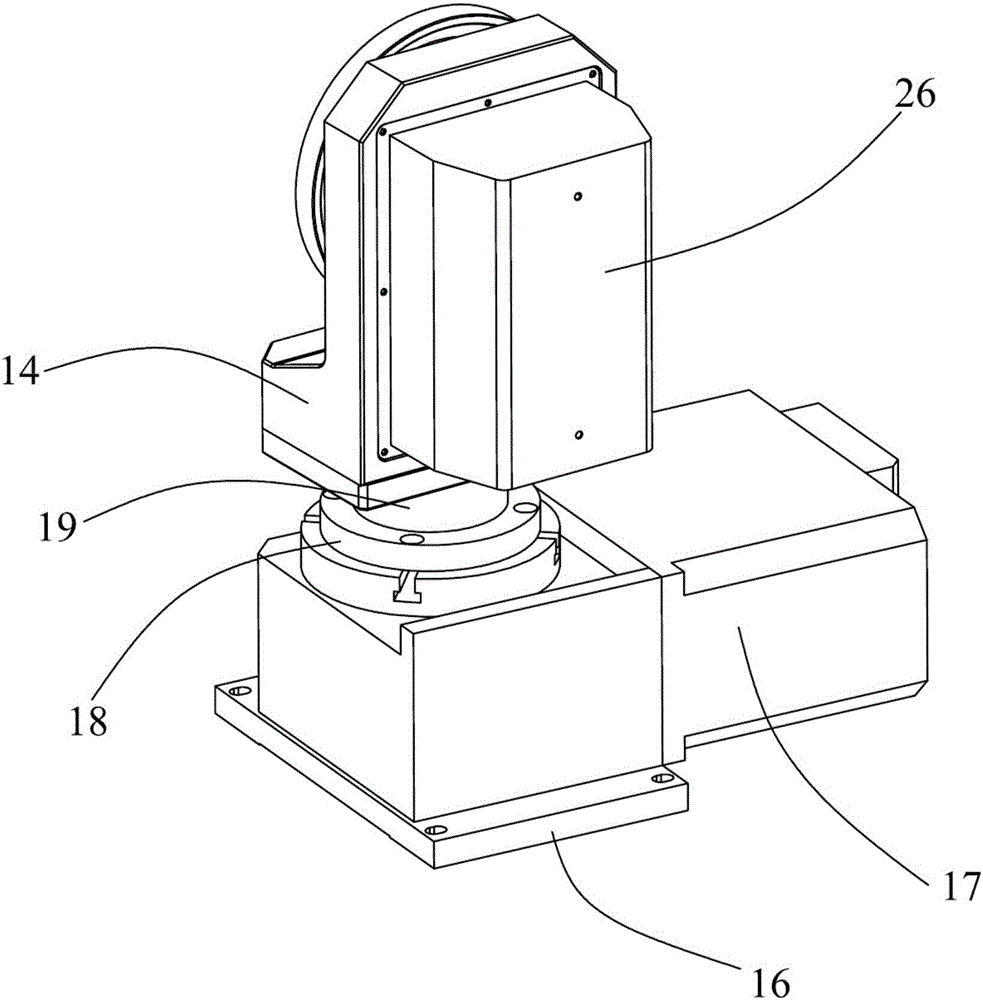

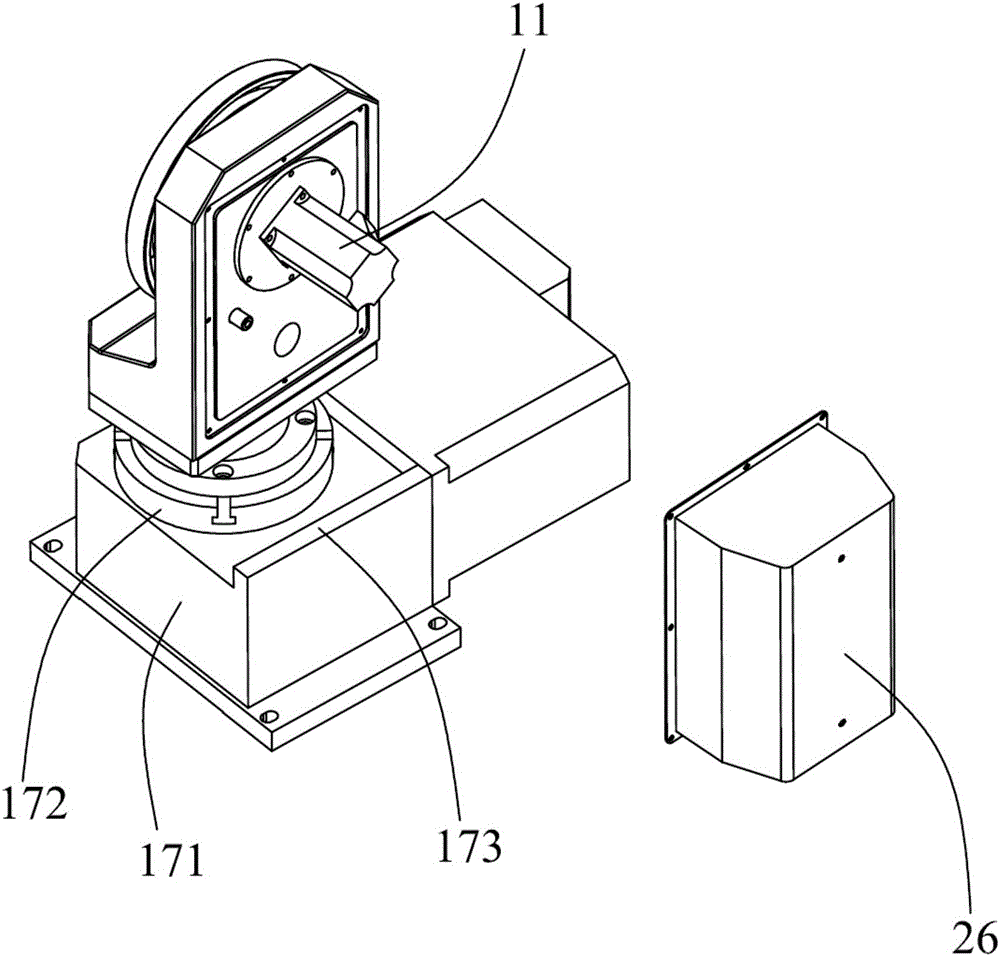

[0023] Such as Figure 1 to Figure 5 As shown, it is a two-dimensional numerical control electric discharge machining turntable 100 according to the present invention, which includes: AC servo motor 11, table top 12, reducer 13, L-shaped plate 14, connecting plate 15, indexing plate connecting plate 16, dividing plate The dial 17, the dial transition plate 18, and the connecting ring 19.

[0024] The AC servo motor 11 extends forward and backward, and the speed reducer 13 is mounted on the front end of the AC servo motor 11 . The table top 12 is connected to the front end of the speed reducer 13, the L-shaped plate 14 has a vertical portion 141 extending in the vertical direction and a horizontal portion 142 extending in the front-rear direction, the horizontal portion 142 is located at the edge of the vertical portion 141 Below, the reducer 13 is acc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap