An anti-collision and anti-turbulence off-road vehicle fuel tank and its control system

A fuel tank and anti-collision technology, which is applied in the field of vehicles, can solve the problems affecting the service life and performance of the fuel tank, the violent shaking of the fuel tank, the impact of the fuel tank wall, etc., and achieve the effect of improving the performance and service life, increasing the service life and protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

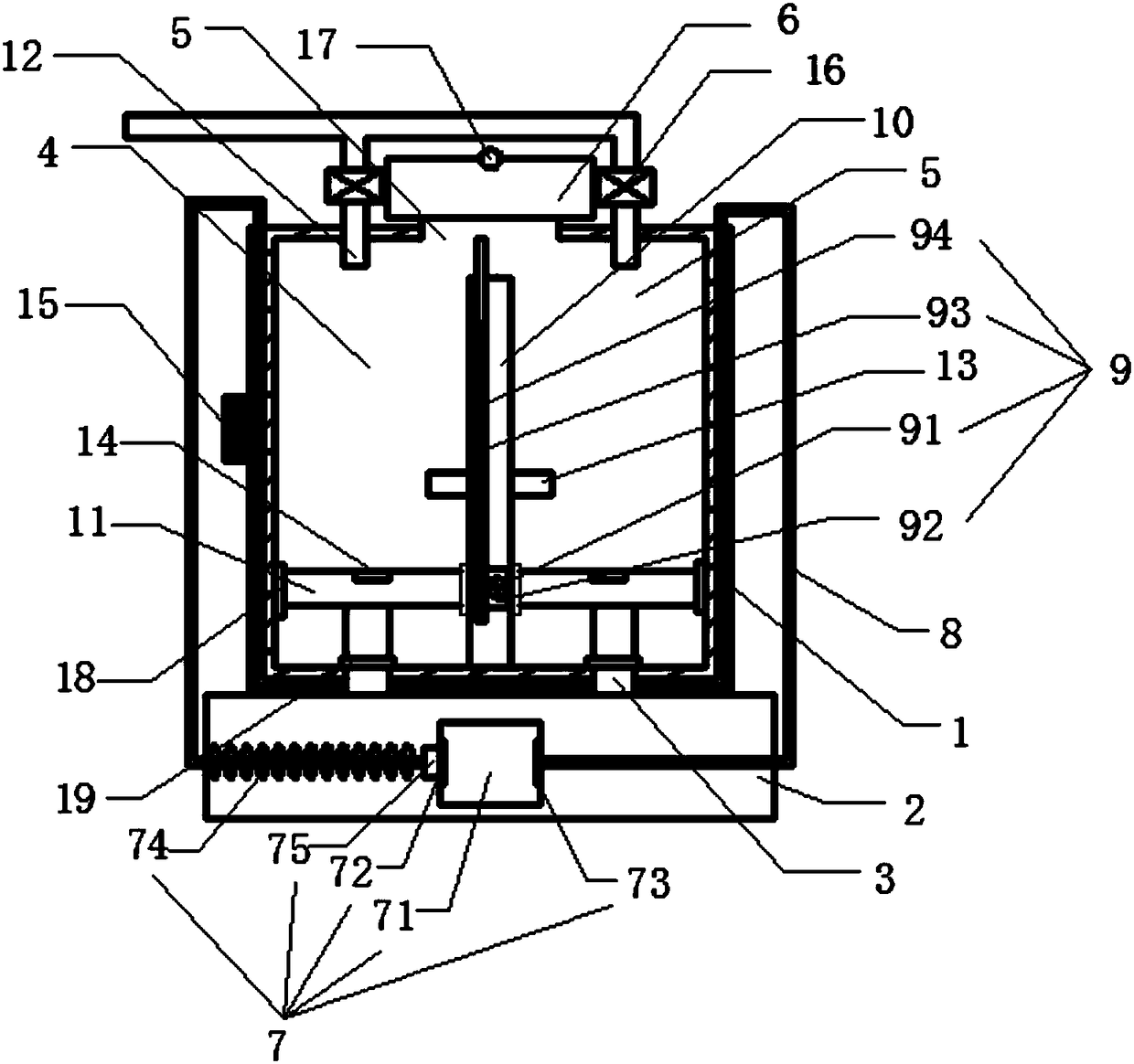

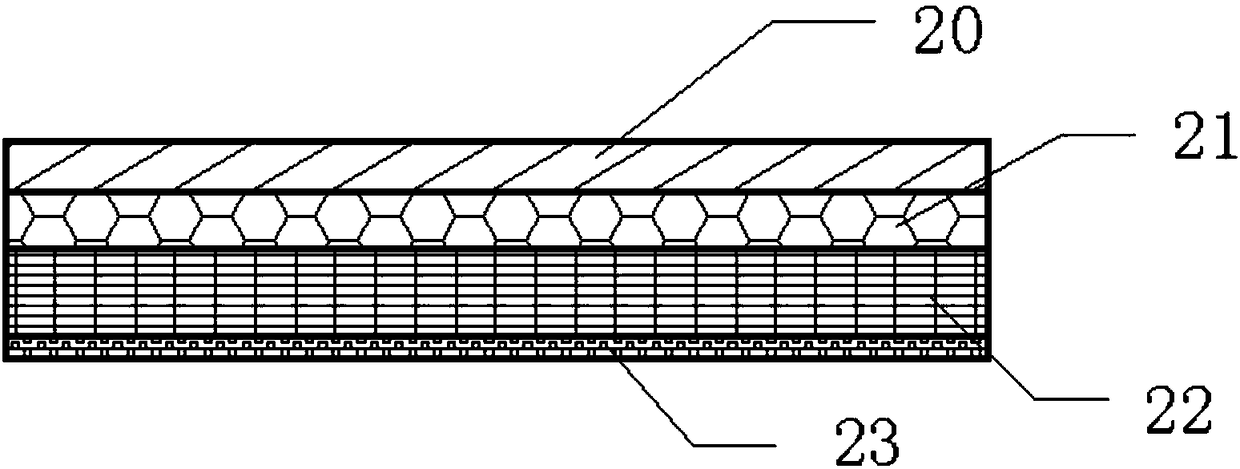

[0026] figure 1 , image 3 and Figure 4 A specific embodiment of the present invention is shown: a fuel tank for an anti-collision and anti-turbulence off-road vehicle, including a body 1, a hydraulic cylinder 2 and a temperature adjustment system 7, the upper part of the body 1 is provided with an oil inlet, and a fuel tank is arranged on the oil inlet The cover 6, the fuel tank cover 6 and the oil inlet are connected by threads, and the side wall of the body 1 is provided with a water pipe 8, wherein the water pipe 8 is connected with the temperature adjustment system 7, and the inside of the body 1 is vertically provided with an oil separator 10 , the body 1 is divided into a first oil tank 4 and a second oil tank 5 by an oil baffle 10, wherein the bottoms of the first oil tank 4 and the second oil tank 5 are provided with an oil baffle 11, and the oil baffle 11 is connected with the inner wall of the body 1 and the partition The oil plate 10 is slidingly connected, the ...

Embodiment 2

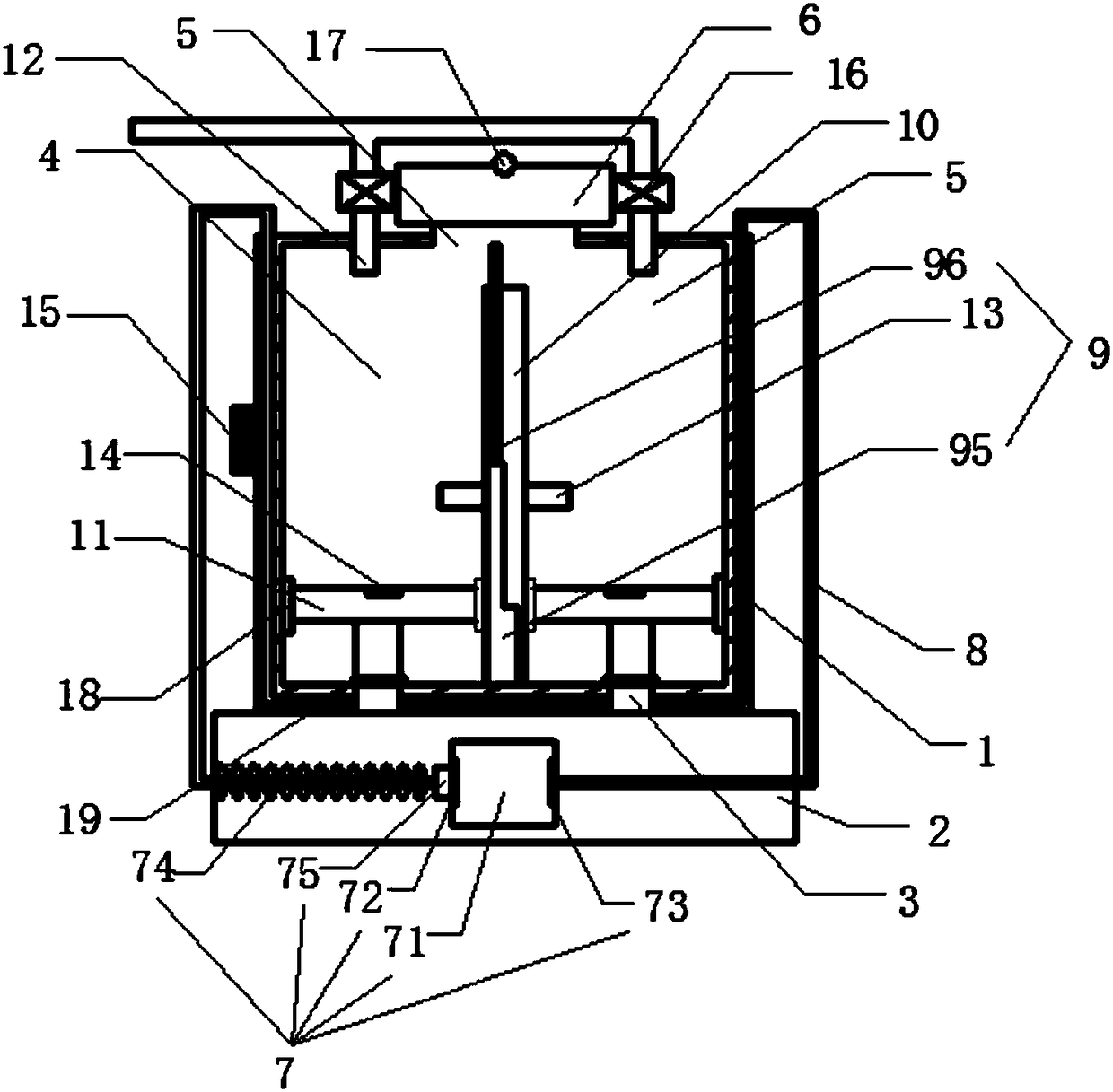

[0038] figure 2 , image 3 and Figure 4 A specific embodiment of the present invention is shown: a fuel tank for an anti-collision and anti-turbulence off-road vehicle, including a body 1, a hydraulic cylinder 2 and a temperature adjustment system 7, the upper part of the body 1 is provided with an oil inlet, and a fuel tank is arranged on the oil inlet The cover 6, the fuel tank cover 6 and the oil inlet are connected by threads, and the side wall of the body 1 is provided with a water pipe 8, wherein the water pipe 8 is connected with the temperature adjustment system 7, and the inside of the body 1 is vertically provided with an oil separator 10 , the body 1 is divided into a first oil tank 4 and a second oil tank 5 by an oil baffle 10, wherein the bottoms of the first oil tank 4 and the second oil tank 5 are provided with an oil baffle 11, and the oil baffle 11 is connected with the inner wall of the body 1 and the partition The oil plate 10 is slidingly connected, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com