Multistage efficient energy absorption seat backrest

A seat back and high-efficiency technology, which is applied in the field of rail transit, can solve problems such as endangering the life safety of passengers, collision between passengers and the back of the train seat, ignoring seat safety research, etc., to achieve efficient absorption and reduce injuries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

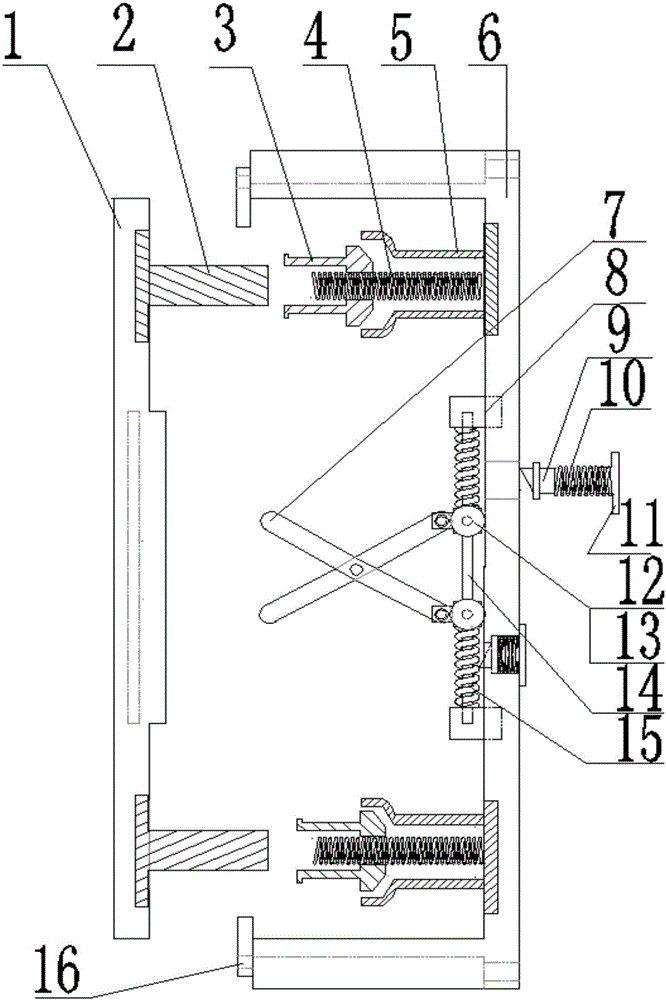

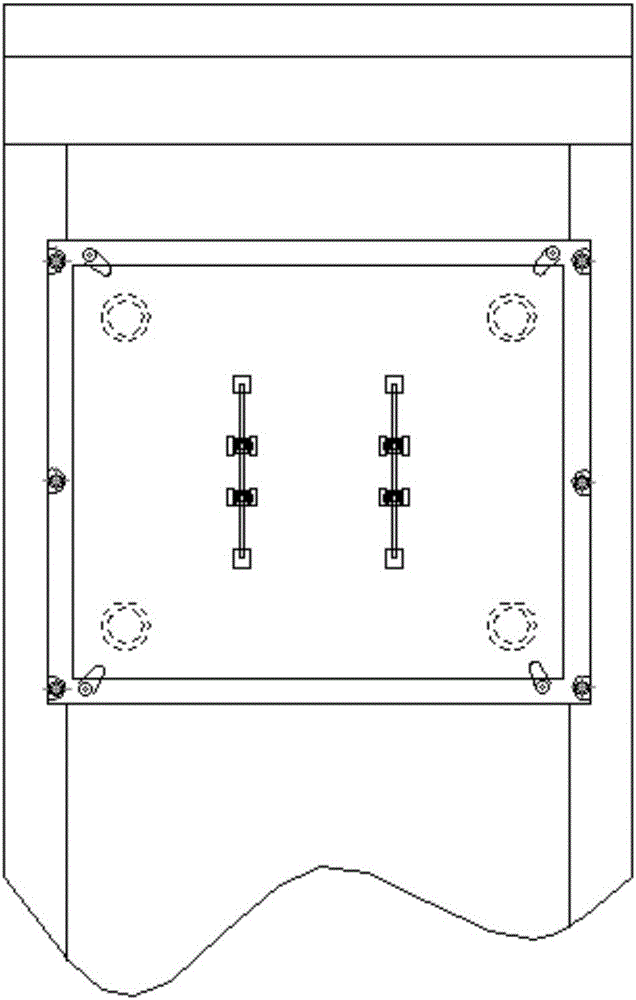

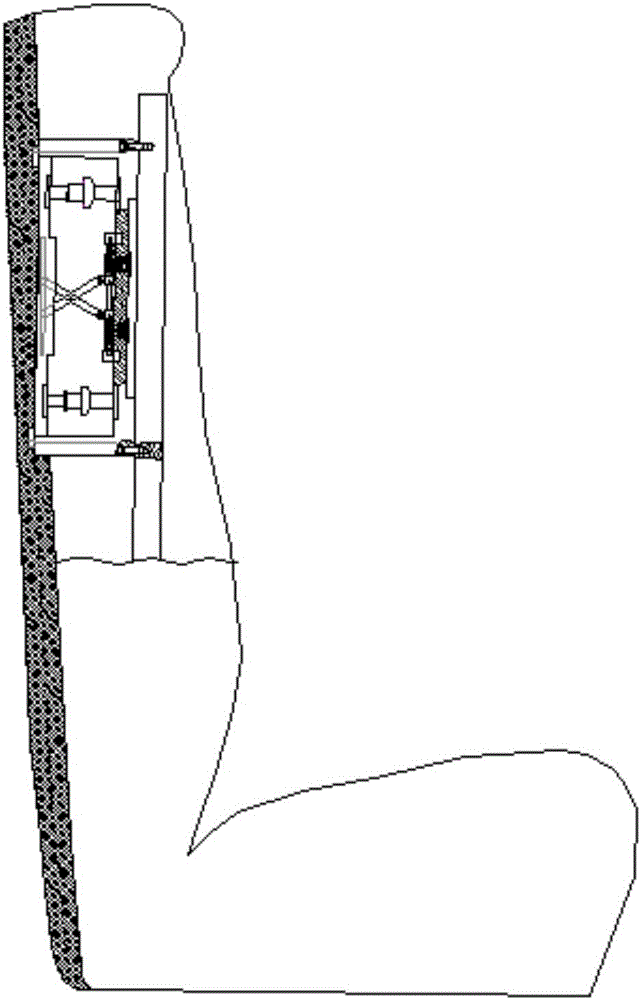

[0027] Such as Figure 1-3 As shown, the multi-stage high-efficiency energy-absorbing seat back of the present invention is provided with a rear fixed plate 1, a front fixed plate 6, and an energy-absorbing device inside; the energy-absorbing device includes two spring-expandable crushing tubes, Buffer folder and spring locking device;

[0028] One end of the spring-expandable crushing tube is connected to the rear fixing plate 1, and the other end is connected to the front fixing plate 6; the two spring-expanding crushing tubes are respectively arranged on the upper and lower parts of the front fixing plate 6;

[0029] The buffer folder is arranged in the middle of the front fixing plate 6; the spring locking device is arranged correspondingly to the buffer folder for locking the buffer folder.

[0030] On the basis of the above scheme, the spring-expandab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com