Novel silicon slice transfer box

A transfer box and silicon wafer technology, which is applied in the types of packaging items, bottle/can parts, container decorations, etc., can solve the problems of inconvenient operation, reduce production efficiency, etc. The effect of improving production and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

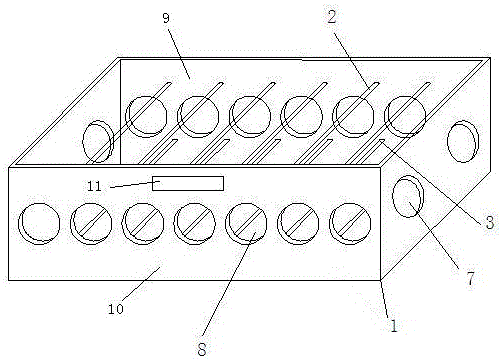

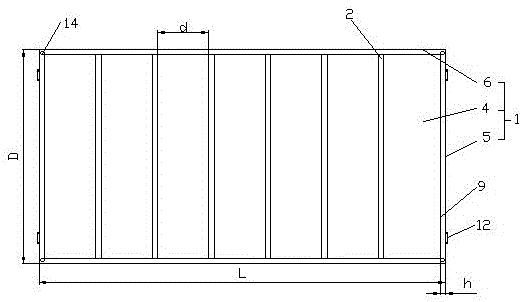

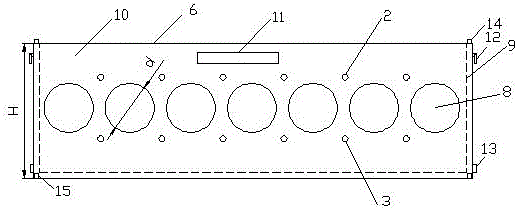

[0020] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] A new type of transfer box for silicon wafers, comprising a box body 1 made of PTFE, a number of first support sticks 2 and second support sticks 3, wherein the box body 1 is in the shape of a cube and includes a bottom plate 4, The first side plate 5 and the second side plate 6, the length L of the box body 1 is 360mm, the width D is 190mm, and the height H is 110mm. There are two first side plates 5, and they are respectively wider than the bottom plate 4. The sides are vertically connected, and the first side plate 5 is provided with a plurality of first round holes 7;

[0022] There are two second side plates 6, and they are vertically connected to the long sides of the bottom plate 4, the second side plates 6 are vertically connected to the first side plates 5, and several second side plates 6 are provided Round holes 8, the plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com