Ultralong telescopic chute tube driving structure

A technology of telescopic chute and driving structure, applied in the direction of spring mechanism, loading/unloading, hoisting device, etc., can solve the problems of chute yaw, jamming, etc., and achieve uniform force, simple structure, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

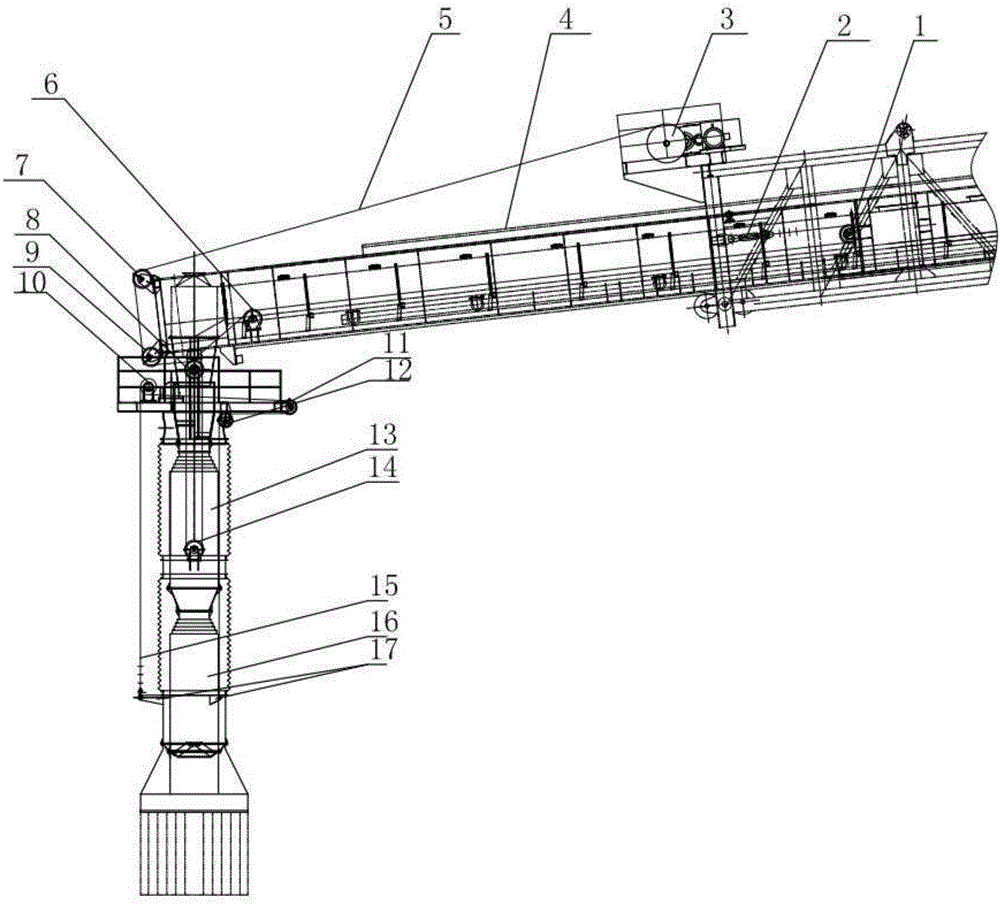

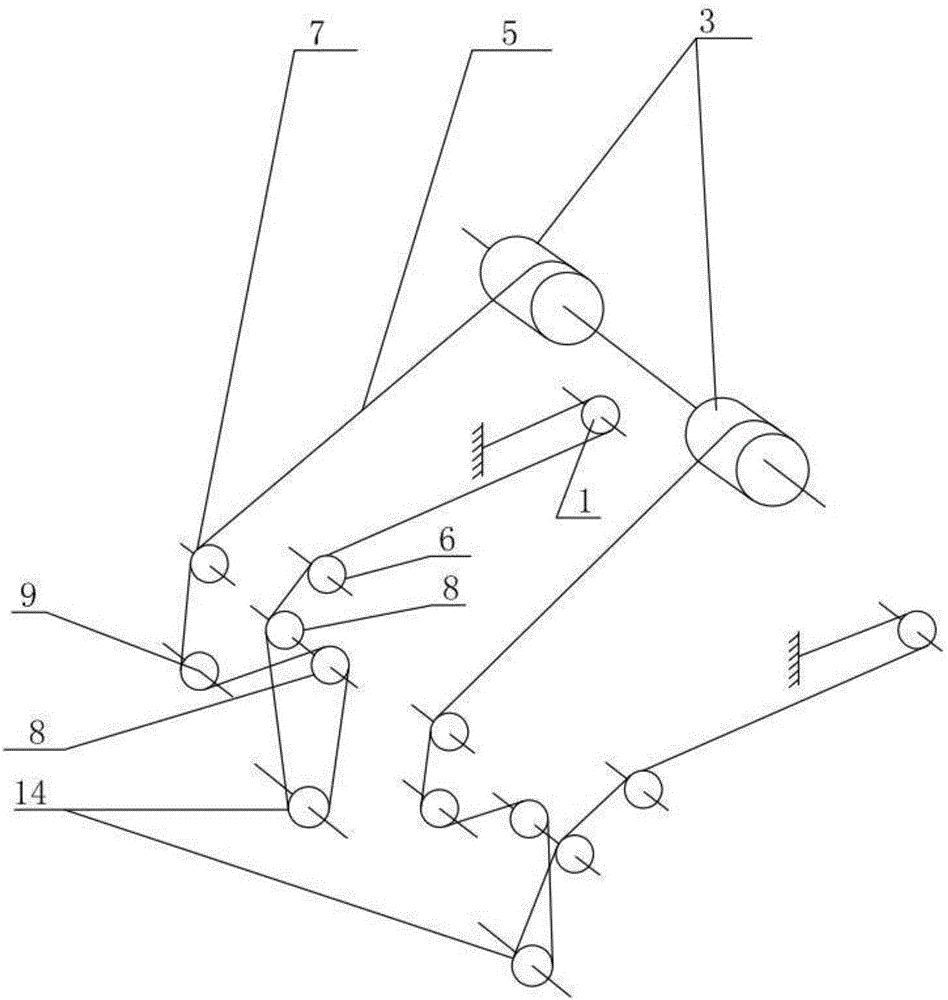

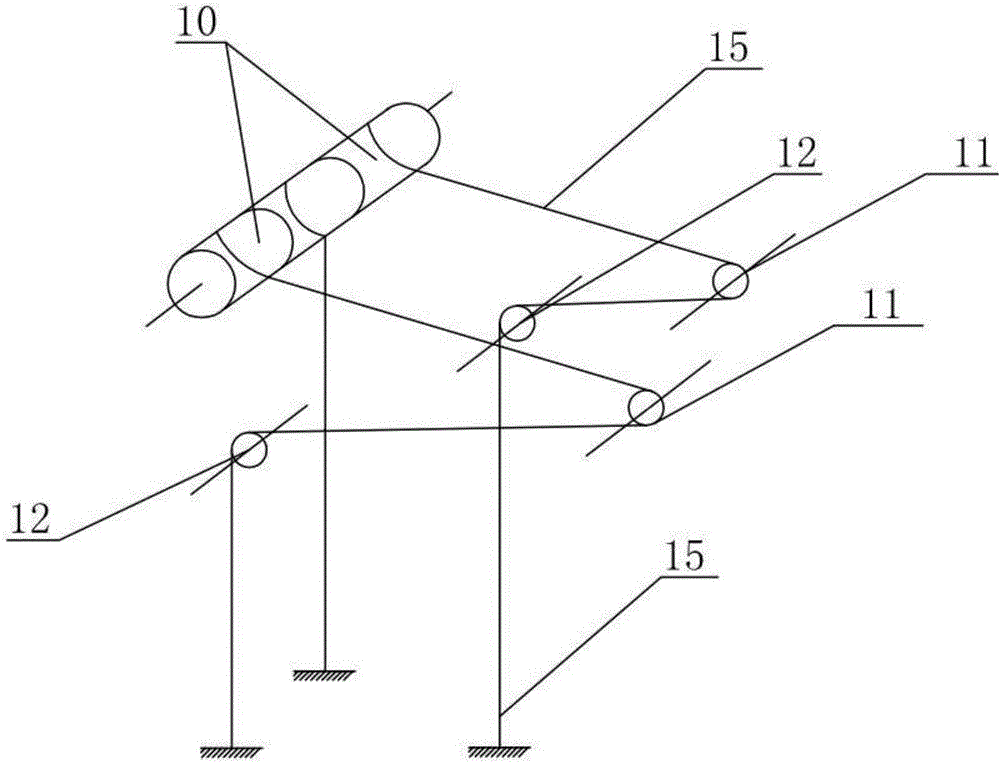

[0022] A super-long telescopic chute driving structure includes a first drive mechanism for pulling the upper chute 13 to stretch and a second drive mechanism for pulling the lower chute 16 to stretch; figure 1 , figure 2 As shown, the specific structure of the first drive mechanism is as follows: it includes two first reels 3 for releasing and receiving the rope, and the first reel 3 for releasing the rope is connected to one end of the first steel wire rope 5 , the other end of the first first steel wire rope 5 passes through the head redirecting pulley block, the upper chute redirecting pulley block, the compensation pulley block and is wound with the adjusting turnbuckle bolt 2; One end of the two first wire ropes 5 is connected, and the other end of the second wire rope 5 passes through the head reversing pulley block, the upper chu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com