Curved cast-in-place concrete beams and construction methods based on shaped quick-release aluminum formwork

A technology of concrete beams and construction methods, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., which can solve the problems of large consumption of materials, high construction cost, and complicated installation of arc-shaped formwork. Achieve the effect of convenient disassembly, simple and fast construction, and prevention of grout leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In this embodiment, the scaffolding erection process, concrete pouring process, formwork hoisting construction, etc. will not be repeated in this embodiment, and the embodiments of the present invention related to structures will be focused on.

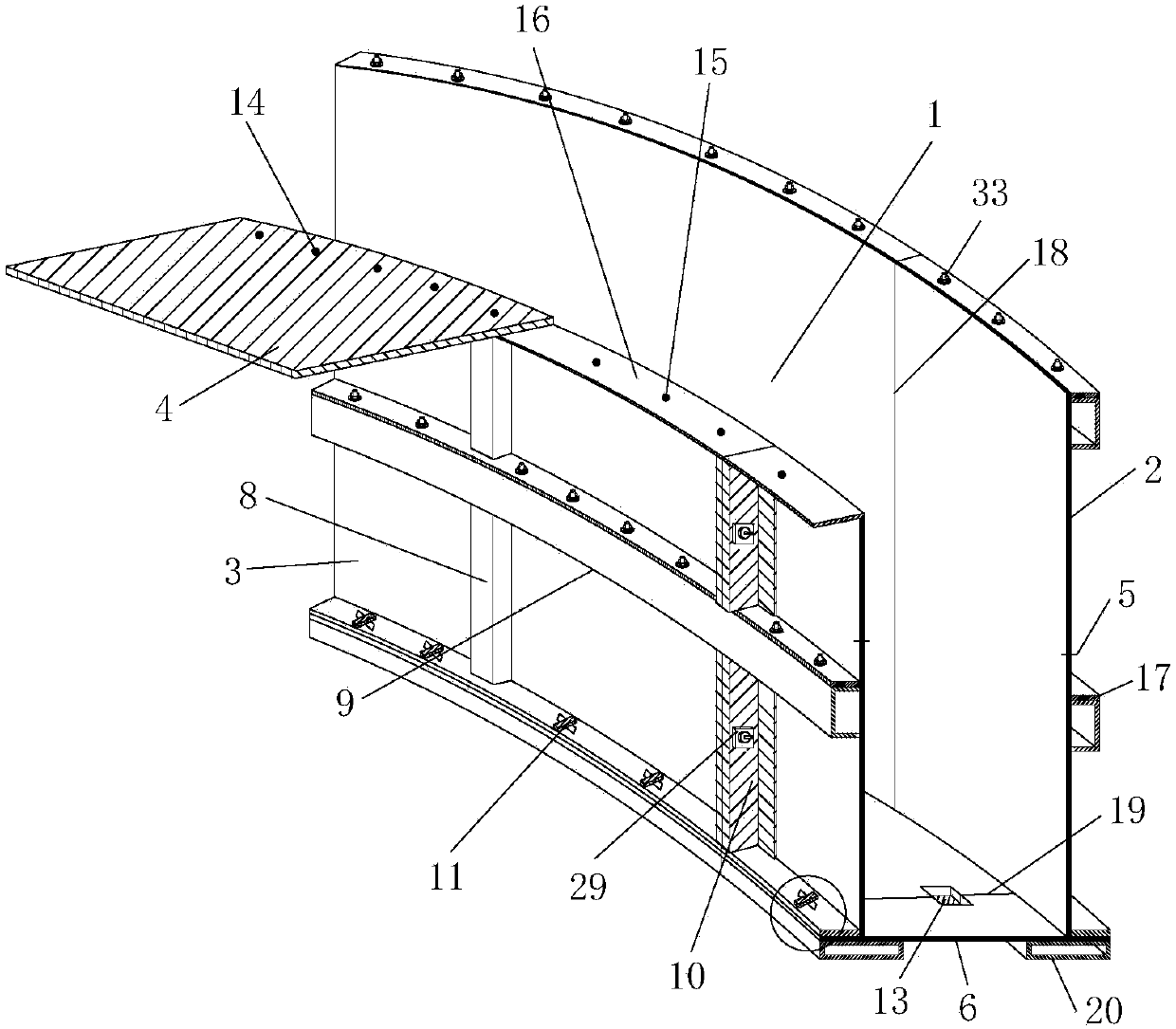

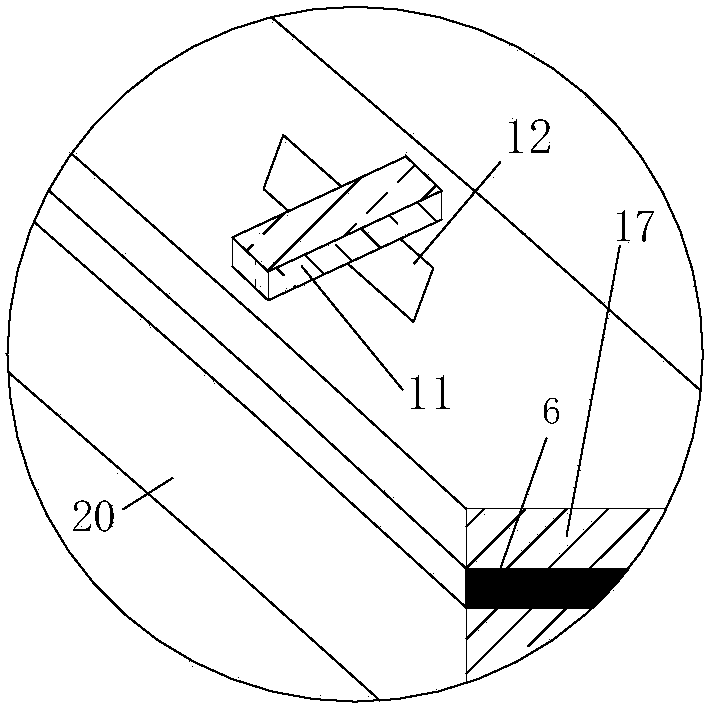

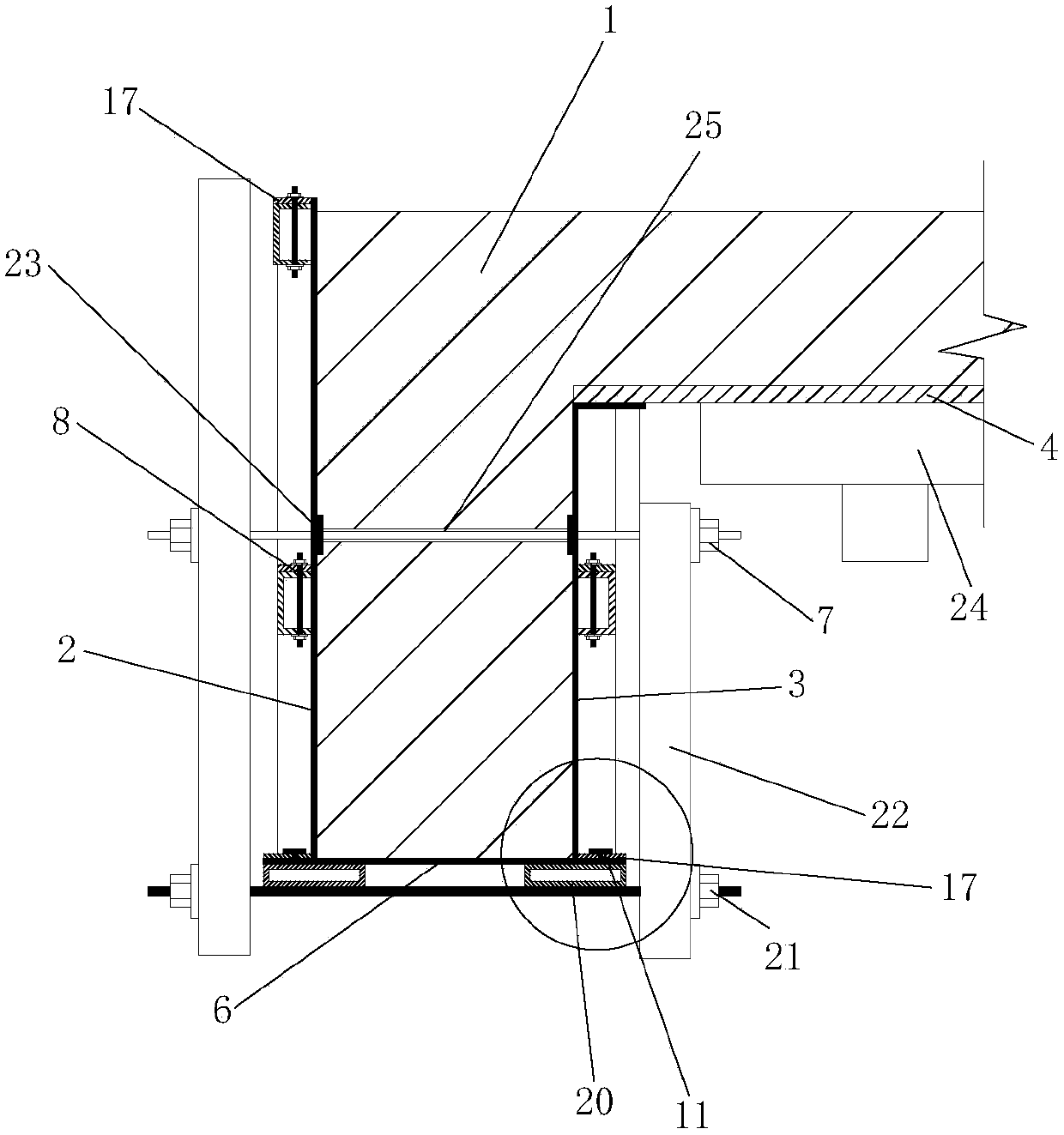

[0037] figure 1 It is a three-dimensional view of the aluminum formwork structure of the arc-shaped cast-in-place concrete beam based on the stereotyped quick-release aluminum formwork and the construction method, figure 2 yes figure 1 Zoom in on the circle, image 3 It is a cross-sectional view of the arc-shaped cast-in-place concrete beam aluminum formwork structure of the present invention, Figure 4 yes image 3 Zoom in on the circle.

[0038] refer to Figure 1~4As shown, the arc-shaped cast-in-place beam formwork is an aluminum alloy formwork with a thickness of 4cm. A grooved aluminum transverse rib 9 is set on the outside of the beam side formwork. The width of the grooved aluminum transverse rib 9 is 80mm and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com