Rapid hoisting method for underground multi-layer double-T-plate structure and positioning fixture thereof

A hoisting method and a technology for positioning fixtures, which are applied in the directions of transportation and packaging, building construction, and load hanging components, etc., and can solve the problem of small hoisting range of small hoisting equipment, small coverage area of boom tower crane, and large load of large hoisting equipment, etc. problems, to achieve the effect of reducing construction safety hazards, improving hoisting efficiency, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

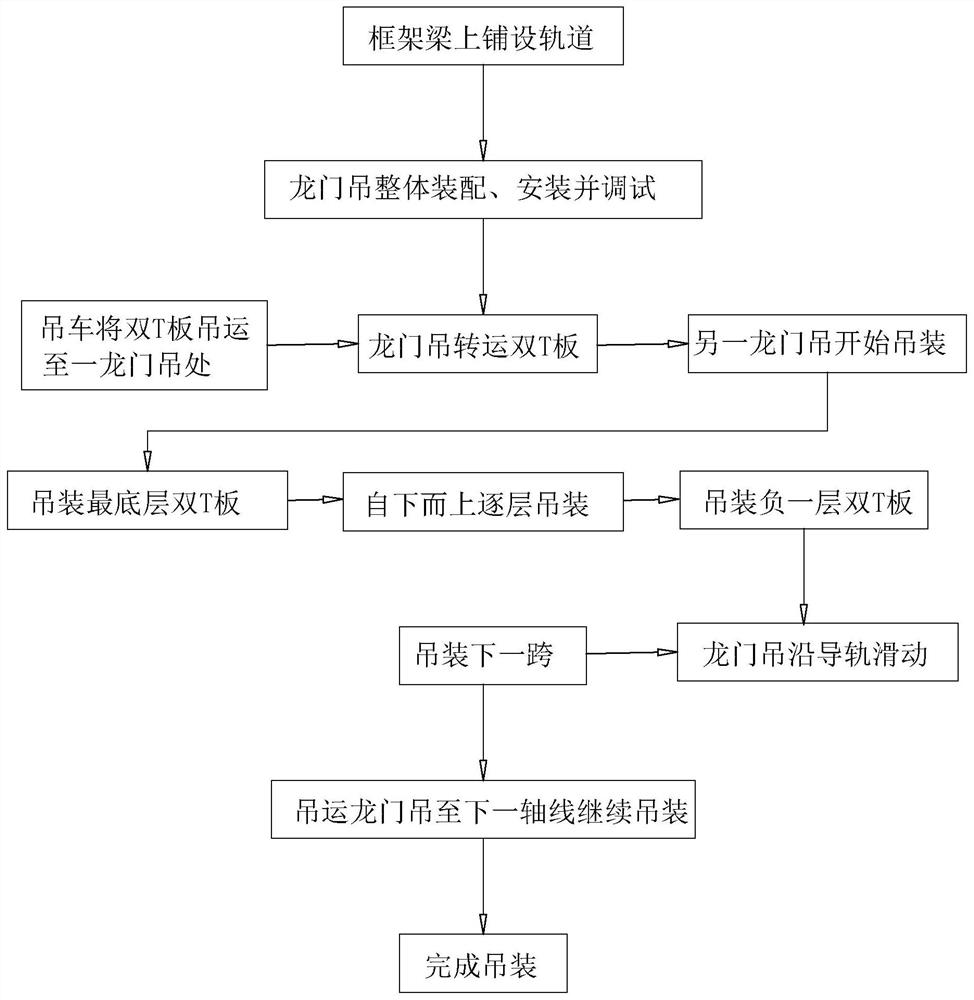

[0060] refer to figure 1 with figure 2 , an underground multi-layer double T plate structure fast hoisting method, comprising the steps of:

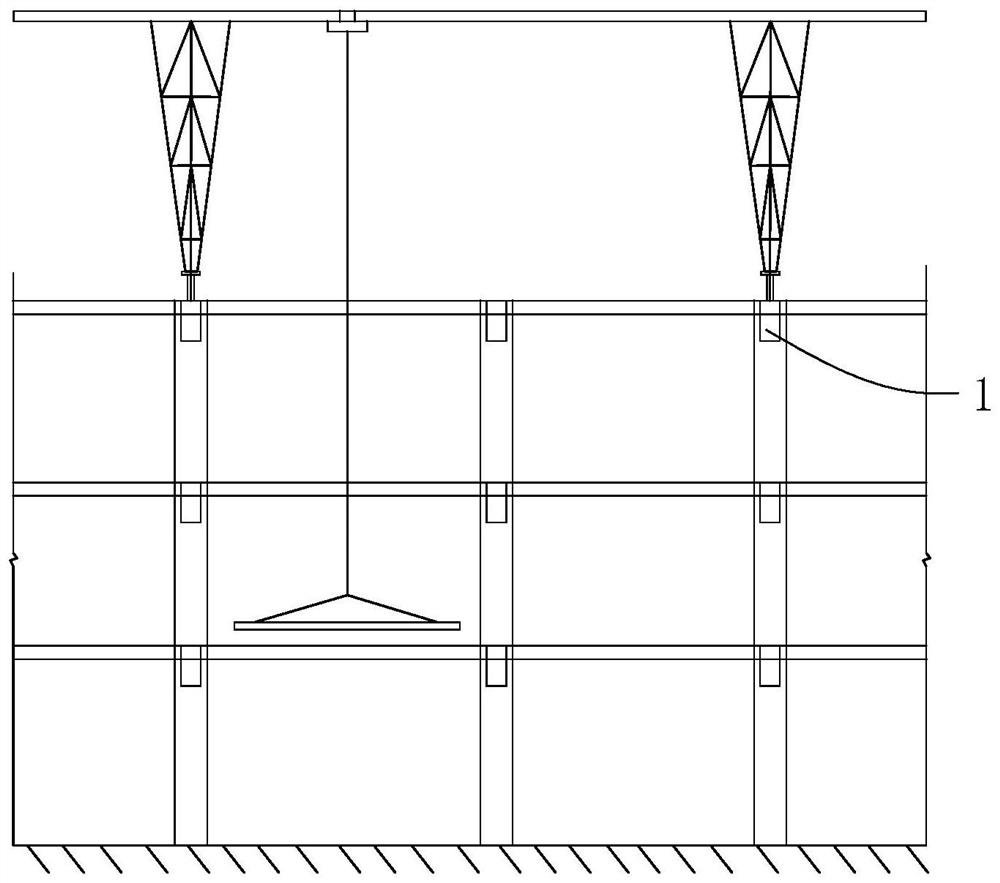

[0061] S1: Install the gantry crane; install the gantry crane on the two parallel frame beams 1 on the first floor of the underground building through several positioning fixtures; transfer the double T-plates to the roof of the first floor of the underground building;

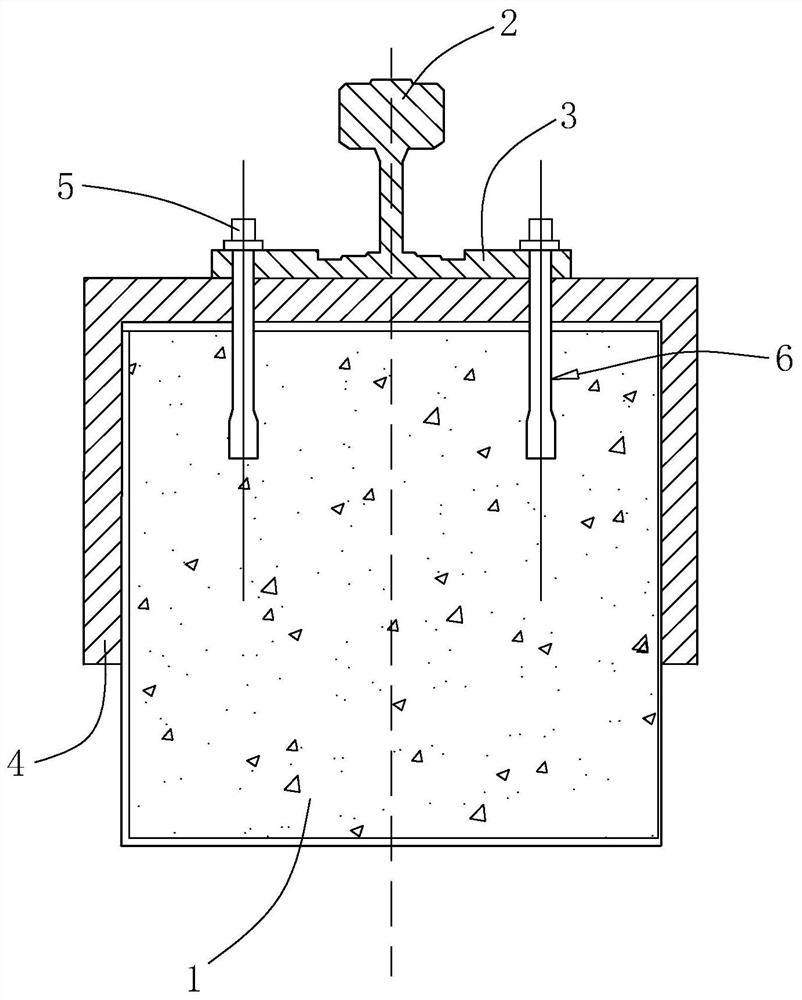

[0062] S11: Install the track: Use several positioning fixtures to install the positioning plate 3 on the two parallel frame beams 1 on the negative floor of the foundation pit of the underground building. The distance between the centers of two adjacent positioning fixtures is 800mm. The specific number depends on the selected gantry crane track. Depends on length; see image 3 , the gantry track includes an integrated guide rail 2 and a positioning plate 3, the positioning plate 3 is arranged on the bottom wall of the guide rail 2 and is symmetrical with respect to ...

Embodiment 2

[0090] The difference between the embodiment of the present application and embodiment 1 is that there are two gantry cranes, and the walking trolleys of two gantry cranes are installed on the two tracks, and the two gantry cranes are installed in parallel on the same group of gantry crane tracks. When hoisting the T-plates, the crane lifts the double T-plates to the roof of the negative floor of the underground building, and the gantry crane near the ground lifts the double T-plates stacked on the roof and transfers them to the roof at the location to be constructed. Another gantry crane lifts the double T-plates and adjusts the hoisting device of the gantry crane to hoist the double T-plates to the lowest floor of the underground building, and hoist them layer by layer from bottom to top.

[0091]During the construction of a gantry crane, it is necessary to repeat the double T-plate transfer first, and then hoist at the same position. Through the cooperation of the two gantry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com