Recovery and reuse equipment for oil-based drilling fluid

An oil-based drilling fluid recycling technology, which is applied in earthwork drilling, wellbore flushing, wellbore/well components, etc., can solve the problems of easily damaged screens, reduced processing capacity of drilling fluid shale shaker, and loss of drilling fluid liquid phase and other problems, to achieve the effect of increasing the processing capacity, easy separation, and lightening the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

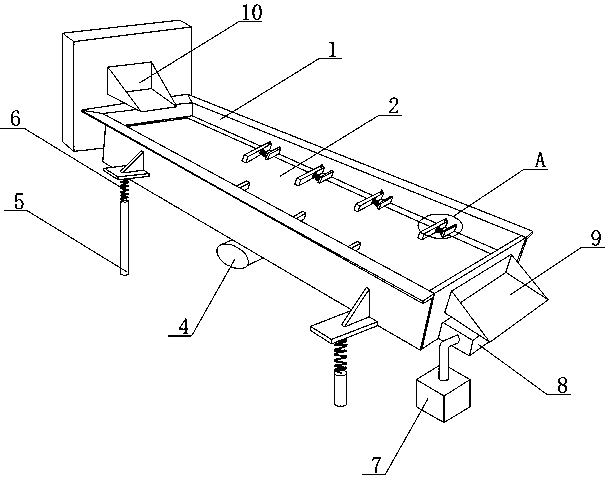

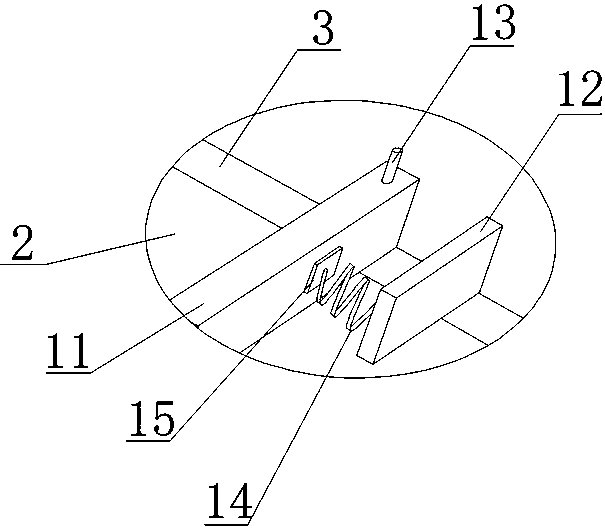

[0025] Such as figure 1 and figure 2 As shown, the present invention is an oil-based drilling fluid recovery and reuse equipment, including a screen box 1, a vibrating motor 4 is arranged under the screen box 1, a support plate is arranged outside the screen box 1, and a tension spring 6 is connected below the support plate. The lower end of the tension spring 6 is connected with a pillar 5, and the top of one end of the screen box 1 is provided with a feed port 10, and the other end is provided with a solid phase discharge port 9, and the screen box 1 is provided with a screen frame 3, and inside the screen frame 3 A screen 2 is provided, and the distance between the screen 2 and the horizontal plane gradually decreases along the direction from the feed port 10 to the solid phase discharge port 9, and a liquid phase discharge box connected to the screen box 1 is provided on the side of the solid phase discharge port 9 8. The liquid phase discharge box 8 is located below the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com