Dustproof steady bearing and locking assembly

A locking component and a stable technology, applied in the field of dust-proof and stable load-bearing locking components, can solve the problems of bolt corrosion, inconvenient operation, etc., achieve the effect of improving the stress condition, enhancing the structural stability, and avoiding loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

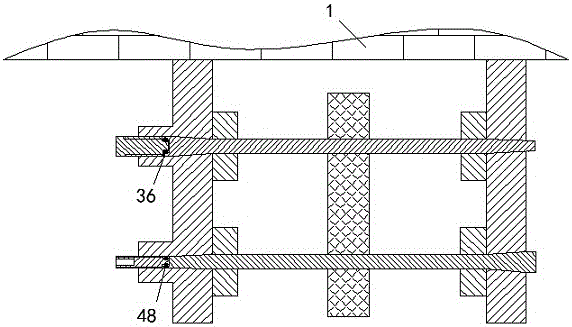

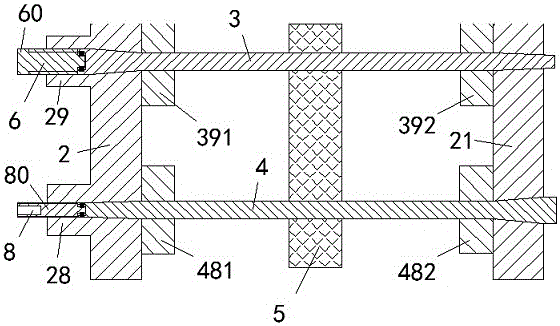

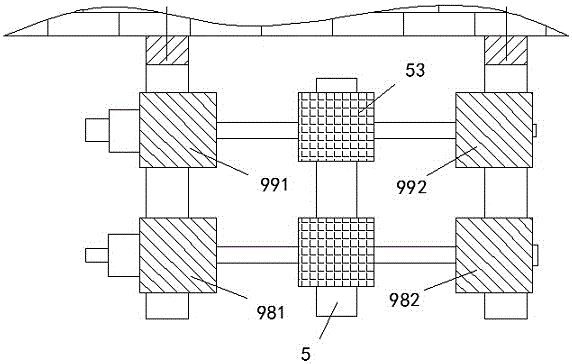

[0013] Combine below Figure 1-7 The present invention will be described in detail.

[0014] According to the embodiment of the present invention, the dust-proof and stable loading locking assembly is used for carrying the load device and locking the loaded load device, including the left bracket 2 and the right bracket 21 for separately fastening on the base 1 and their respective Both pass through the rear locking rod 3 and the front locking rod 4 of the left bracket 2 and the right bracket 21, wherein the rear locking rod 3 includes a rear rod main body and is connected to the left end of the rear rod main body through a rear thrust bearing 36. To the fixedly connected pushing stud member 6, the front locking rod 4 includes a front rod main body and a pull screw sleeve 8 axially fixedly connected to the left end of the front rod main body through a front thrust bearing 48, wherein , the outer circumferences of the push-off stud member 6 and the pull-screw set 8 are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com