Small household garbage incineration treatment system and incineration treatment method

A technology of domestic waste incineration and treatment system, which is applied in the field of incineration treatment and small-scale domestic waste incineration treatment system in small towns. The effects of British resynthesis, complete combustion, and stable furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described below in conjunction with accompanying drawing:

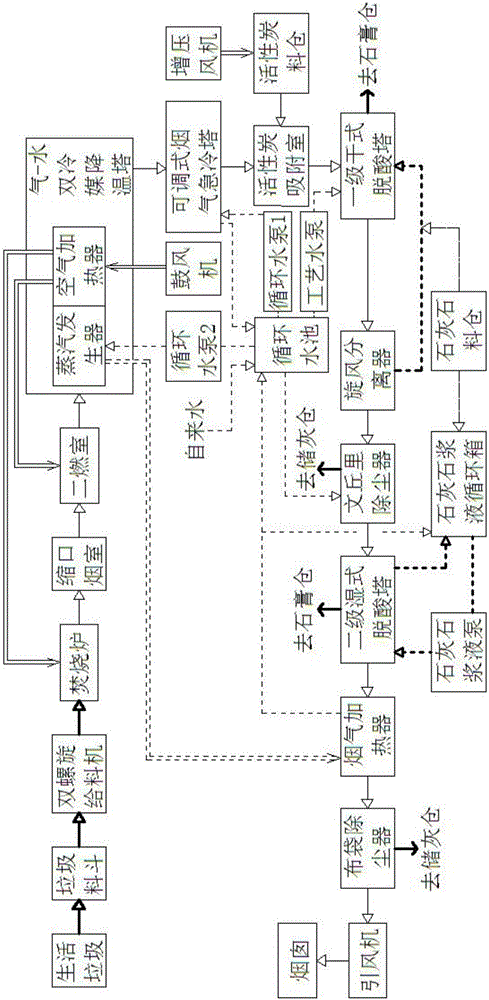

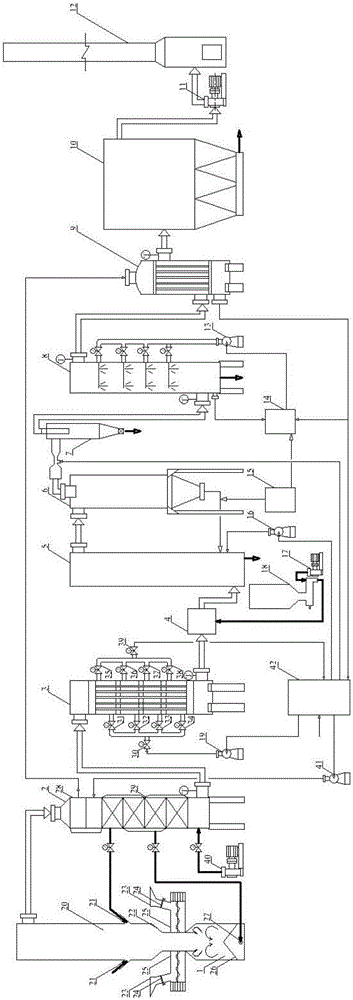

[0030] Such as figure 1 , a small domestic waste incineration treatment system, including a feeding device, an incineration device, a heat energy utilization device, an adjustable flue gas quenching tower, a flue gas purification device and various pipelines;

[0031] The feeding device is composed of a garbage hopper 23, a double-screw feeder 25 installed below the hopper through a descending pipeline, and a one-way cover valve 24 installed in the descending pipeline between the garbage hopper 23 and the double-screw feeder 25; The internal structure of the double-screw feeder 25 in the feeding device is a double-helix structure with an adjustable wheelbase. By adjusting the wheelbase, the garbage with a wide size distribution can enter the incinerator 1 evenly, and the double-helix structure is not easy to cause bridging and blockage; The one-way cover valve 24 can only be op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com